Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Machine Shop Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Machine Shop Supervisor so you can tailor your answers to impress potential employers.

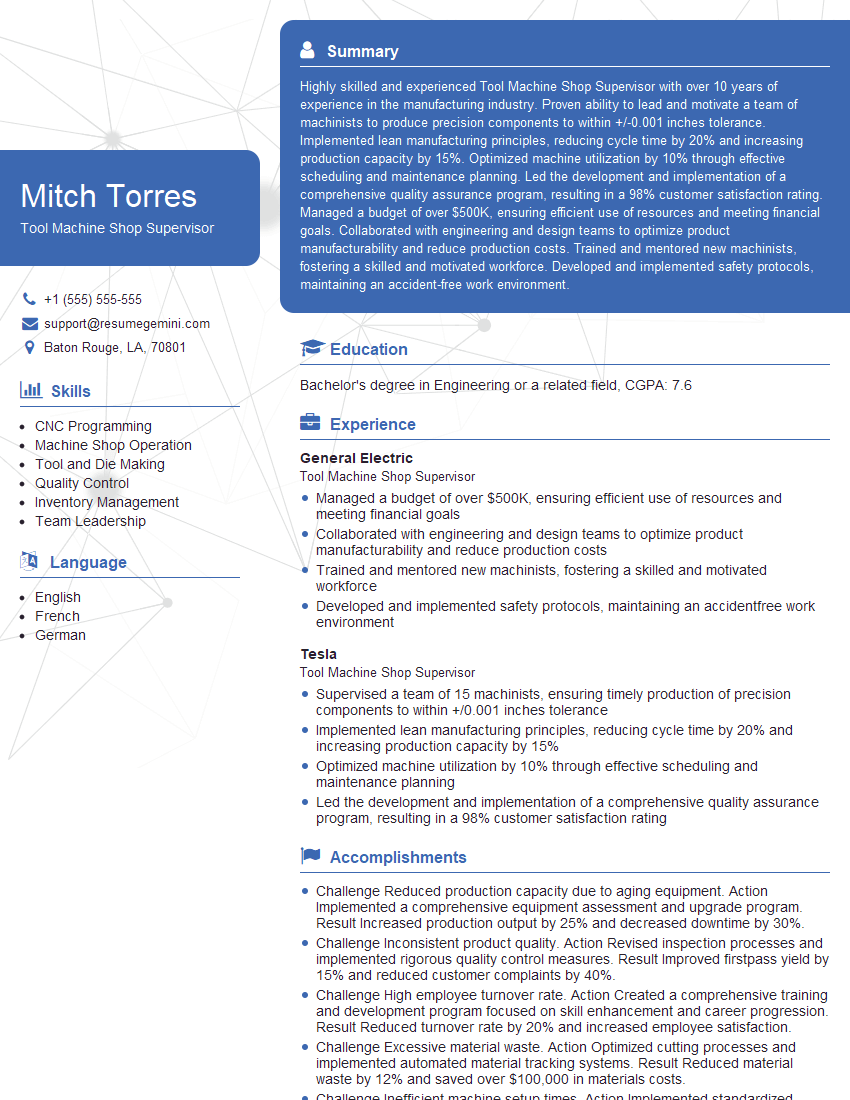

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Machine Shop Supervisor

1. How would you plan and coordinate the production schedule for the tool machine shop?

To plan and coordinate the production schedule for the tool machine shop, I would follow these steps:

- Review and analyze customer orders to determine production requirements.

- Identify the necessary resources, including machines, tools, and personnel.

- Develop a production plan that outlines the sequence of operations and the estimated time for each step.

- Assign tasks to staff and set clear deadlines.

- Implement a monitoring system to track progress and identify potential bottlenecks.

- Make adjustments to the schedule as needed to ensure efficient and timely production.

2. What techniques do you use to ensure the accuracy and precision of machined parts?

Quality Control Measures

- Establish and maintain precise tolerances for all machining operations.

- Implement rigorous inspection procedures at various stages of production.

- Utilize specialized measuring instruments and gauges to verify dimensions and specifications.

Training and Development

- Provide comprehensive training to machinists on precision machining techniques.

- Encourage continuous improvement and skill development.

Equipment Maintenance

- Regularly inspect and calibrate all machine tools to ensure accuracy.

- Implement a preventive maintenance schedule to minimize equipment downtime.

3. How do you manage inventory and ensure that materials are available for production?

To manage inventory and ensure that materials are available for production, I use the following strategies:

- Establish a comprehensive inventory system to track incoming and outgoing materials.

- Implement a reorder point system to trigger replenishment orders when inventory levels reach a minimum threshold.

- Maintain strong relationships with suppliers to ensure timely delivery of materials.

- Optimize storage space and implement efficient inventory handling procedures.

- Monitor inventory costs and conduct regular audits to identify areas for improvement.

4. Describe your experience with tool design and selection for machining operations.

In my previous role, I was responsible for designing and selecting tools for various machining operations. My experience includes:

- Analyzing workpiece materials and machining requirements to determine appropriate tool geometry and materials.

- Selecting and specifying cutting tools, such as end mills, drills, and taps, based on their suitability for the specific operation.

- Optimizing tool speeds and feeds to maximize efficiency and tool life.

- Working closely with tool vendors to stay updated on the latest tool technologies and advancements.

5. How do you ensure the safety of employees in the tool machine shop?

Ensuring the safety of employees in the tool machine shop is of utmost importance. I implement the following measures:

- Develop and enforce comprehensive safety protocols and procedures.

- Provide thorough safety training to all employees and contractors.

- Conduct regular safety inspections and audits to identify potential hazards.

- Establish clear reporting mechanisms for safety incidents and near misses.

- Promote a culture of safety awareness and accountability.

6. How do you stay updated on the latest advancements in tool machine technology?

To stay updated on the latest advancements in tool machine technology, I employ various strategies:

- Attend industry conferences and exhibitions.

- Subscribe to trade publications and technical journals.

- Stay informed about research and development in the field.

- Network with professionals and experts in the industry.

- Participate in training and certification programs to enhance my knowledge and skills.

7. How do you motivate and lead a team of machinists?

I believe in motivating and leading a team of machinists through the following principles:

- Establish clear goals and expectations.

- Provide regular feedback and recognition for achievements.

- Create a positive and supportive work environment.

- Empower team members and encourage their input.

- Foster a culture of continuous improvement.

8. What is your experience with computer-aided manufacturing (CAM) software?

I have extensive experience with CAM software, including:

- Using CAD/CAM software to create toolpaths and NC programs.

- Optimizing toolpaths for efficiency and accuracy.

- Simulating machining operations to identify potential issues.

- Troubleshooting and resolving CAM-related problems.

9. How do you handle quality control and ensure the quality of machined parts?

To ensure the quality of machined parts, I follow these steps:

- Develop and implement a comprehensive quality control plan.

- Establish clear quality standards and specifications.

- Conduct regular inspections at various stages of the machining process.

- Utilize statistical process control techniques to monitor and improve quality.

- Identify and address any non-conformance issues promptly.

10. How do you manage maintenance and repairs of the tool machine shop?

To manage maintenance and repairs of the tool machine shop, I implement the following strategies:

- Establish a preventive maintenance schedule to minimize equipment downtime.

- Hire a skilled maintenance team or contract with a service provider for major repairs.

- Maintain a spare parts inventory for critical components.

- Monitor equipment performance and identify potential issues early on.

- Maintain records of all maintenance and repair activities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Machine Shop Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Machine Shop Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supervises all aspects of tool machine operations, including planning, scheduling, and executing production orders.

1. Production Management

Ensures efficient and effective utilization of tooling and equipment, maximizing production output.

- Develops and implements production schedules to meet customer demand.

- Monitors production progress, identifying and resolving bottlenecks.

2. Quality Control

Maintains high standards of product quality by adhering to specifications and industry best practices.

- Inspects finished products, ensuring they meet customer specifications.

- Conducts quality audits and implements corrective actions when necessary.

3. Team Management

Leads and supervises a team of tooling machine operators, providing guidance and support.

- Assigns tasks, provides training and coaching to employees.

- Creates a positive, motivated team environment.

4. Safety Compliance

Ensures adherence to all safety regulations and procedures to maintain a safe work environment.

- Conducts safety inspections and provides training on safe work practices.

- Investigates accidents and implements corrective measures.

Interview Tips

Interview preparation is crucial to showcase your skills and qualifications for the Tool Machine Shop Supervisor position. Here are some tips to help you succeed.

1. Research the Company and Position

Thoroughly research the company’s website and industry to understand their products, services, and values. Dive into the specific job requirements to identify key skills and responsibilities.

- Study the job description and note the essential qualifications and experience required.

- Visit the company’s website to learn about their mission, culture, and recent news.

2. Practice Your Answers

Anticipate common interview questions and prepare concise, well-structured answers that highlight your relevant skills and experience. Use the STAR (Situation, Task, Action, Result) method to effectively present your accomplishments.

- Prepare examples of situations where you successfully supervised a team or managed production operations.

- Quantify your achievements whenever possible, using specific metrics or data to demonstrate your impact.

3. Highlight Your Leadership Skills

Emphasize your leadership and management abilities, explaining how you effectively motivate, train, and guide your team. Describe instances where you resolved conflicts, fostered collaboration, and created a positive work environment.

- Share examples of how you implemented innovative solutions or improved processes to enhance team performance.

- Discuss your approach to employee development and how you nurture the growth of your team members.

4. Showcase Your Technical Expertise

Demonstrate your comprehensive understanding of tool machine operations, including programming, setup, and maintenance procedures. Be prepared to discuss industry trends and best practices in tooling and manufacturing.

- Highlight your knowledge of different types of tool machines, CNC programming languages, and inspection techniques.

- Explain how you stay updated with the latest advancements in tooling and manufacturing technology.

5. Ask Thoughtful Questions

Asking insightful questions during the interview shows your interest and engagement. Prepare a few well-thought-out questions that demonstrate your curiosity and desire to learn more about the company and the position.

- Ask about the company’s growth plans and how the Tool Machine Shop Supervisor role contributes to those goals.

- Inquire about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Machine Shop Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Machine Shop Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.