Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Maker Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

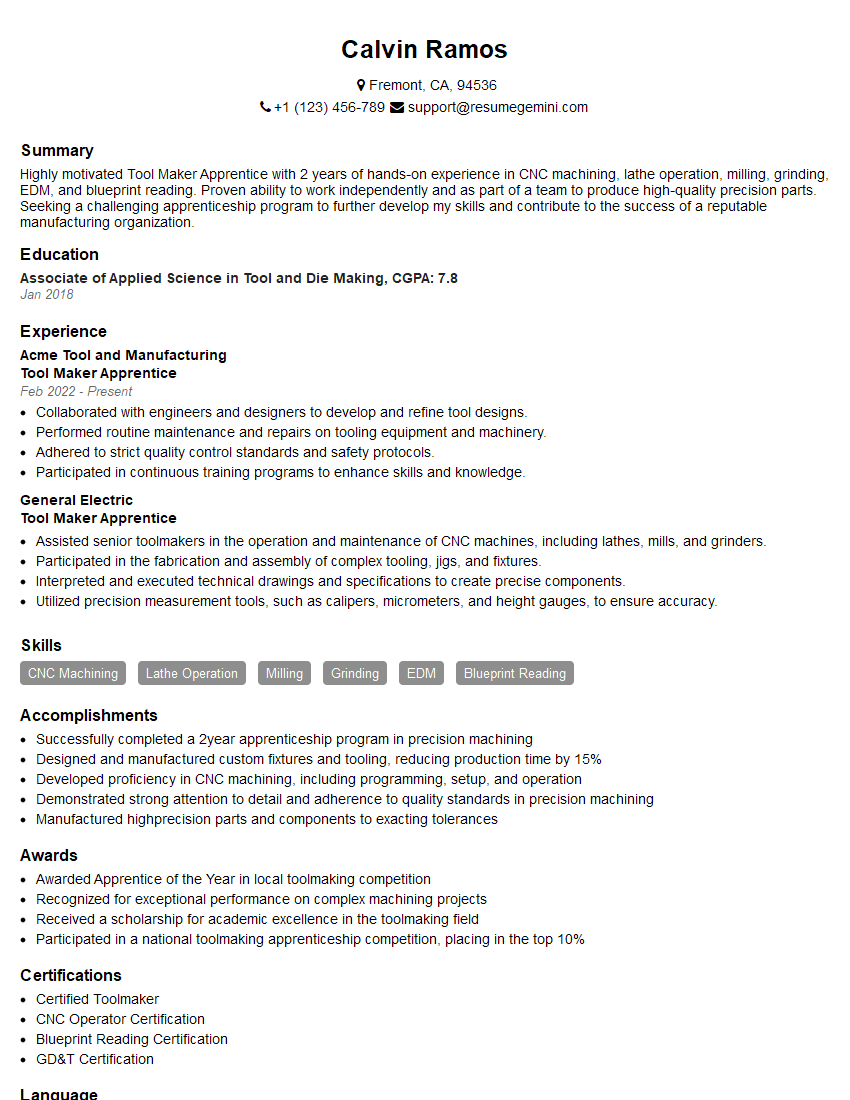

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Maker Apprentice

1. Describe your understanding of the role of a Tool Maker Apprentice?

As a Tool Maker Apprentice, I would be responsible for assisting experienced Tool Makers in the design, development, and production of tools, dies, and fixtures. My duties may include operating various machine tools such as lathes, mills, grinders, and wire EDMs, as well as performing tasks like setting up and operating CNC machines, inspecting and measuring parts, and maintaining tools and equipment.

2. Explain the different types of materials used in tool making?

Metals

- Tool steels: Used for cutting tools due to their hardness and wear resistance.

- Stainless steels: Used for corrosion resistance in applications like food processing.

- Aluminum: Used for lightweight and durable tools and fixtures.

Plastics

- Polycarbonate: Used for clear and impact-resistant parts.

- Delrin: Used for low-friction and wear-resistant components.

- Nylon: Used for its strength and flexibility.

3. What are the essential steps involved in precision grinding?

- Proper workpiece preparation: Ensuring the workpiece is securely mounted and has a stable base.

- Selecting the correct grinding wheel: Choosing the appropriate abrasive, grit size, and bond.

- Setting up the machine: Calibrating the machine according to the desired specifications.

- Grinding: Operating the machine carefully and monitoring the process to achieve the required precision.

- Checking and measuring: Using precision instruments to verify the accuracy and surface finish of the ground workpiece.

4. Explain the process of heat treating tools and dies?

- Annealing: Heating the tool to a high temperature and slowly cooling it to relieve stresses and increase toughness.

- Hardening: Heating the tool to a critical temperature and rapidly cooling it to increase hardness and wear resistance.

- Tempering: Reheating the hardened tool to a lower temperature and cooling it slowly to reduce brittleness and improve toughness.

- Cryogenic treatment: Cooling the tool to extremely low temperatures to further enhance hardness and reduce wear.

5. How do you ensure the accuracy and quality of your work?

- Using precision measuring instruments such as calipers, micrometers, and gauges.

- Following established quality control procedures.

- Inspecting parts at various stages of production.

- Seeking feedback from experienced Tool Makers.

- Continuously improving my skills through training and practice.

6. Describe your experience with different welding processes?

- TIG welding: Used for precise and high-quality welds on thin materials.

- MIG welding: Used for faster welding of thicker materials.

- Stick welding: Used for general-purpose welding applications.

- Brazing: Used for joining dissimilar metals or for creating strong, corrosion-resistant joints.

7. Explain the safety precautions that must be taken when working with machine tools?

- Wearing appropriate safety gear such as eye protection, gloves, and earplugs.

- Ensuring that machines are properly guarded and maintained.

- Following established safety procedures.

- Being aware of potential hazards and taking necessary precautions.

- Reporting any unsafe conditions or incidents promptly.

8. Describe your experience with CAD/CAM software?

- Proficient in using software such as SolidWorks, AutoCAD, and Mastercam.

- Skilled in creating 3D models, generating toolpaths, and simulating machining processes.

- Able to use CAD/CAM software to assist in the design and manufacturing of tools, dies, and fixtures.

9. What are the key qualities and skills required to be a successful Tool Maker?

- Strong technical skills and knowledge of machining processes.

- Attention to detail and accuracy.

- Problem-solving and analytical abilities.

- Ability to read and interpret blueprints and technical drawings.

- Good communication and teamwork skills.

10. Why are you interested in a career as a Tool Maker?

I have always been fascinated by the precision and craftsmanship involved in tool making. The opportunity to create and build tools that play a vital role in various industries excites me.

Furthermore, the prospect of continuous learning and development in this field motivates me. I am eager to expand my knowledge and skills in tool making and contribute to the production of high-quality tools that meet the demands of modern manufacturing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Maker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Maker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tool Maker Apprentice is responsible for assisting experienced tool makers in the fabrication, assembly, repair, and maintenance of tools, dies, jigs, fixtures, and other precision parts.

1. Assist in Tool Fabrication and Assembly

– Assist in the fabrication of new tools, dies, and other components.

– Help assemble and fit together components to create complete tools.

2. Repair and Maintenance

– Perform routine maintenance on tools to ensure they are in good working condition.

– Repair or replace damaged or worn components.

3. Quality Control

– Inspect completed tools to ensure they meet specifications.

– Assist in developing and maintaining quality control procedures.

4. Other Duties

– May be required to operate various machines, such as lathes, mills, and grinders.

– May be responsible for maintaining inventory of tools and materials.

Interview Tips

Interview preparation is crucial for a successful interview. Here are some tips to help you ace your Tool Maker Apprentice interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and goals.

– Visit the company’s website to learn about their history, products, and services.

– Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

– Think about your skills, experience, and qualifications and how they relate to the job requirements.

– Prepare examples of your work that demonstrate your abilities and knowledge.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a manufacturing environment.

– Choose clothes that are comfortable and allow you to move around easily.

– Avoid wearing clothing that is too revealing or too casual.

4. Be Polite and Respectful

Remember to be polite and respectful to everyone you meet during the interview process, from the receptionist to the interviewer.

– Greet people with a smile and make eye contact.

– Be patient and answer questions honestly and thoroughly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Maker Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.