Feeling lost in a sea of interview questions? Landed that dream interview for Tool Polishing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tool Polishing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

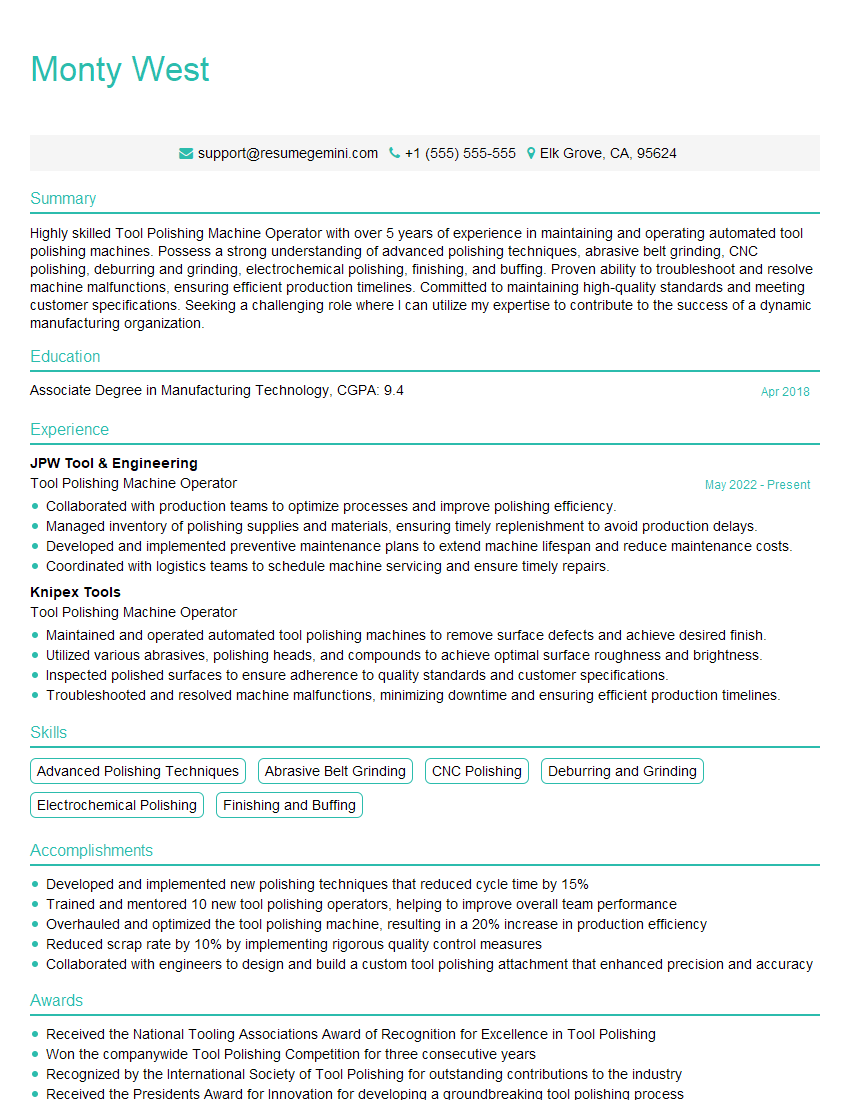

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Polishing Machine Operator

1. Describe the types of polishing tools used in tool polishing?

In tool polishing, various types of polishing tools are utilized to achieve different desired finishes and precision levels. Some of the common types include:

- Abrasive Belts: Flexible belts coated with abrasive particles used for grinding and shaping.

- Polishing Wheels: Rotating wheels made of various materials like felt, cotton, or leather, used with abrasive compounds for fine finishing.

- Buffing Wheels: Similar to polishing wheels but with softer materials for achieving a high-luster finish.

- Honing Stones: Natural or synthetic stones used to refine sharp edges and remove burrs.

- Diamond Compounds: Advanced abrasives used for precision finishing and polishing hard materials.

2. Explain the importance of surface preparation before polishing?

Surface Inspection:

- Checking for any imperfections, scratches, or defects that need to be addressed.

Cleaning and Degreasing:

- Removing dirt, oil, or grease that can interfere with the polishing process.

Abrasive Blasting or Grinding:

- Using abrasive techniques to remove excess material or shape the surface.

Proper preparation ensures:

- Improved adhesion of polishing compounds.

- Achieving the desired surface finish.

- Avoiding rework or polishing defects.

3. What are the different types of polishing compounds and their applications?

- Abrasive Compounds: Used for cutting and shaping, contain coarse abrasive particles.

- Fine Polishing Compounds: For smoothing and refining surfaces, have finer abrasive particles.

- Color Compounds: Enhance surface appearance and provide color.

- Liquid Compounds: Suspensions of abrasive particles in a liquid medium, easy to apply and control.

- Paste Compounds: Thick, viscous compounds that are applied with a cloth or brush.

4. How do you maintain the accuracy and precision of the polishing machine?

- Regular Calibration: Using precision measuring instruments to ensure accuracy.

- Spindle Maintenance: Lubricating and adjusting the spindle to minimize vibration and maintain alignment.

- Tooling Alignment: Ensuring that the polishing tools are properly aligned with the workpiece.

- Monitoring: Regularly checking the machine’s performance and making adjustments as needed.

- Preventive Maintenance: Following manufacturer’s guidelines for maintenance to avoid breakdowns.

5. Describe the process of polishing a complex curved surface?

- Surface Preparation: Cleaning, degreasing, and preparing the surface.

- Tool Selection: Choosing flexible polishing tools like buffs or abrasive belts to conform to the curve.

- Compound Selection: Using fine polishing compounds for a smooth finish.

- Technique: Gently applying the tool to the surface while following the contour.

- Inspection: Regularly checking the progress and adjusting the technique as needed.

6. How do you troubleshoot common polishing defects, such as swirl marks or pitting?

- Swirl Marks: Caused by uneven pressure or improper tool movement; adjust technique and use finer compounds.

- Pitting: Occurs due to surface imperfections or contamination; improve surface preparation and use cleaner compounds.

- Scratches: Caused by abrasive particles or sharp edges; inspect tools and workpiece, replace or repair as needed.

- Burnishing: Excessive heat build-up; reduce pressure or use a lower speed, check machine settings.

- Orange Peel: Caused by uneven compound application; thin the compound or apply it more evenly.

7. How do you ensure the consistency and repeatability of the polishing process?

- Standardized Procedures: Establishing clear instructions and checklists for all steps.

- Tool Calibration: Ensuring that tools are properly calibrated and maintained.

- Quality Control: Regularly inspecting finished products to meet specifications.

- Data Logging: Recording process parameters to track and analyze results.

- Continuous Improvement: Identifying areas for improvement and implementing changes to enhance consistency.

8. Describe the safety precautions to be observed while operating a tool polishing machine?

- Protective Gear: Wearing appropriate eye protection, gloves, and dust mask.

- Machine Guarding: Ensuring all guards are in place and functioning.

- Electrical Safety: Checking for proper grounding and avoiding loose wires.

- Proper Handling: Operating the machine only when necessary and using tools as intended.

- Ventilation: Ensuring adequate ventilation to remove polishing dust and fumes.

9. How do you stay up-to-date with the latest advancements in tool polishing techniques?

- Industry Publications: Subscribing to trade magazines and attending industry events.

- Online Resources: Researching online forums, articles, and technical papers.

- Training and Workshops: Participating in training programs and workshops offered by equipment manufacturers or industry organizations.

- Collaboration with Colleagues: Exchanging knowledge and best practices with fellow tool polishers.

- Continuous Learning: Staying proactive in seeking new information and technologies.

10. What are the key qualities and skills required to be a successful tool polishing machine operator?

- Technical Proficiency: In-depth knowledge of polishing techniques, materials, and equipment.

- Attention to Detail: Meticulous focus on achieving precise and high-quality finishes.

- Problem-Solving Ability: Troubleshooting issues and finding solutions to ensure smooth operation.

- Physical Dexterity: Ability to handle and maneuver tools with precision and stability.

- Communication Skills: Effective communication with colleagues, supervisors, and customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Polishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Polishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Polishing Machine Operators play a crucial role in the manufacturing process by using specialized machines to grind and polish tools and components to precise specifications.

1. Tool Grinding and Polishing

Operate a variety of tool polishing machines, such as belt grinders, buffing wheels, and polishing lathes, to remove burrs, imperfections, and excess material from tools and components.

- Use abrasives, polishing compounds, and other materials to achieve the desired surface finish.

- Monitor the grinding and polishing process to ensure tools and components meet required specifications.

2. Machine Setup and Maintenance

Set up and calibrate polishing machines according to specifications.

- Inspect machines for wear and tear, and perform routine maintenance as needed.

- Troubleshoot and resolve machine malfunctions promptly to minimize downtime.

3. Quality Control

Inspect polished tools and components to ensure they meet quality standards.

- Use measuring tools and gauges to verify dimensions, surface finish, and other critical parameters.

- Identify and resolve any defects or inconsistencies in the polishing process.

4. Work Environment and Safety

Maintain a clean and organized work area, following established safety protocols.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a mask.

- Handle tools and equipment safely, adhering to company policies and regulations.

Interview Tips

Preparing thoroughly for a Tool Polishing Machine Operator interview is essential to showcase your skills and qualifications effectively. Here are some top tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, industry trends, and the specific role you are applying for. This knowledge will help you understand the company’s values, business goals, and the context of the position.

- Research the company’s products, services, and target market.

- Review industry publications and websites to stay abreast of the latest developments.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in operating tool polishing machines and your ability to achieve precise finishes.

- Provide specific examples of your work, quantifying your accomplishments whenever possible.

- Share your knowledge of polishing techniques, abrasives, and quality control procedures.

3. Demonstrate Safety Awareness and Attention to Detail

Stress your commitment to safety and your ability to work meticulously in a fast-paced environment.

- Describe your experience with safety protocols and your adherence to company policies.

- Provide examples of how you have identified and resolved quality issues in your previous roles.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the position and the company.

- Ask about the company’s growth plans and its commitment to innovation.

- Inquire about the specific responsibilities of the role and the opportunities for professional development.

5. Practice and Seek Feedback

Practice your answers to common interview questions and seek feedback from a friend or mentor.

- Record your responses and listen back to them to identify areas for improvement.

- Ask for constructive criticism to refine your answers and delivery.

Next Step:

Now that you’re armed with the knowledge of Tool Polishing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tool Polishing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini