Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Repairer so you can tailor your answers to impress potential employers.

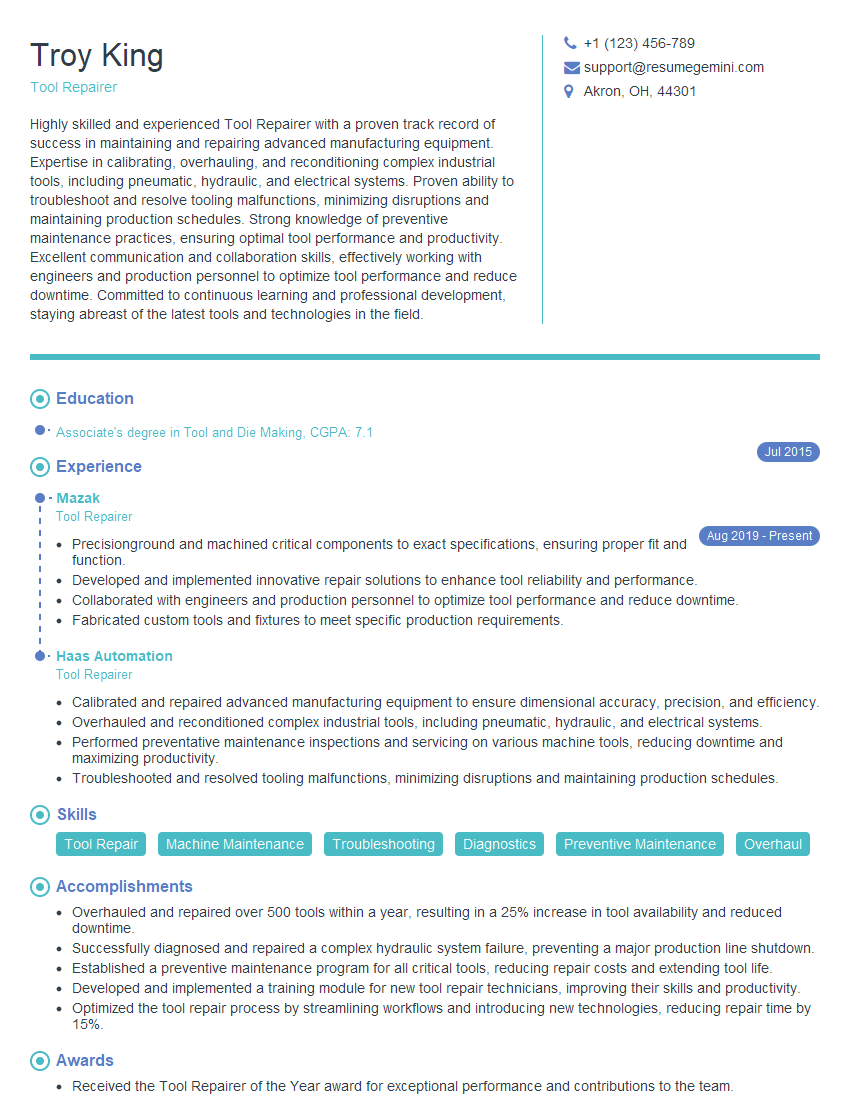

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Repairer

1. How do you diagnose and repair a faulty pneumatic tool?

To diagnose and repair a faulty pneumatic tool, I typically follow these steps:

- Visually inspect the tool for any obvious damage, such as leaks or cracks.

- Check the air supply to the tool by attaching a pressure gauge to the inlet port. The pressure should be within the manufacturer’s specified range.

- Lubricate all moving parts of the tool, as per the manufacturer’s instructions.

- Check the tool’s trigger and valve assembly for proper operation. This may involve disassembling the tool and inspecting the components for wear or damage.

- If necessary, replace any worn or damaged parts and reassemble the tool.

- Test the tool to ensure that it is operating properly.

2. How do you troubleshoot and repair a malfunctioning hydraulic tool?

Inspecting the Tool

- Visually inspect the tool for any leaks, cracks, or other signs of damage.

- Check the hydraulic fluid level and condition.

- Inspect the hoses and fittings for any leaks or damage.

Testing the Tool

- Connect the tool to a hydraulic power source.

- Operate the tool and observe its performance.

- Check for any unusual noises, vibrations, or other signs of malfunction.

Troubleshooting and Repair

- If the tool is not operating properly, troubleshoot the problem by isolating the issue.

- Repair or replace any damaged components.

- Bleed the hydraulic system to remove any air.

3. What are the common safety precautions that must be observed when working with high-voltage electrical tools?

When working with high-voltage electrical tools, it is crucial to observe the following safety precautions:

- Always wear appropriate personal protective equipment (PPE), including insulated gloves, safety glasses, and a hard hat.

- Ensure that the work area is well-lit and free of clutter.

- Use only tools that are rated for the voltage of the electricity you are working with.

- Never work on live electrical circuits. Always isolate the circuit before starting any work.

- Be aware of the location of all electrical outlets and wires in the work area.

- Never use metal tools or ladders when working with electricity.

- If you are unsure about any aspect of the work, consult with a qualified electrician.

4. What are the different types of power tools used in construction and what are their applications?

There are a wide variety of power tools used in construction, each with its own specific applications. Some of the most common types of power tools include:

- Drills: Used for making holes in various materials, such as wood, metal, and concrete.

- Saws: Used for cutting through various materials, such as wood, metal, and plastic.

- Sanders: Used for smoothing and finishing surfaces.

- Grinders: Used for grinding and shaping metal.

- Impact wrenches: Used for tightening and loosening bolts and nuts.

- Nail guns: Used for driving nails into wood.

- Staple guns: Used for stapling materials together.

5. What are some of the most common problems that you have encountered while repairing tools?

Some of the most common problems that I have encountered while repairing tools include:

- Worn or damaged parts.

- Electrical problems, such as loose connections or faulty switches.

- Hydraulic leaks.

- Pneumatic leaks.

- Overheating.

- Improper lubrication.

6. What are some of the challenges that you have faced while working as a Tool Repairer?

Some of the challenges that I have faced while working as a Tool Repairer include:

- Working with a variety of tools and equipment.

- Diagnosing and repairing complex problems.

- Meeting deadlines.

- Working in a fast-paced environment.

- Keeping up with new technologies.

7. What are some of the tips that you would give to someone who is new to the role of Tool Repairer?

Here are some tips that I would give to someone who is new to the role of Tool Repairer:

- Get familiar with the different types of tools and equipment that you will be working with.

- Develop good troubleshooting skills.

- Be patient and methodical in your work.

- Keep up with new technologies.

- Be willing to learn from others.

8. How do you stay up-to-date with the latest developments in tool repair technology?

I stay up-to-date with the latest developments in tool repair technology by:

- Reading industry publications.

- Attending trade shows and conferences.

- Taking online courses.

- Networking with other tool repairers.

9. What are your career goals for the next 5 years?

My career goals for the next 5 years are to:

- Become a certified Tool Repairer.

- Start my own tool repair business.

- Develop new and innovative tool repair techniques.

- Teach tool repair classes.

- Become a leader in the tool repair industry.

10. Why are you interested in working for our company?

I am interested in working for your company because:

- You are a leading provider of tool repair services.

- You have a reputation for quality and customer service.

- You offer opportunities for professional development.

- Your company culture is a good fit for me.

- I am excited about the opportunity to contribute to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Repairers are responsible for maintaining, repairing, and troubleshooting tools and equipment. They also perform preventive maintenance to ensure that tools are in optimal condition.

1. Inspect and Diagnose

Tool Repairers inspect tools and equipment to identify any defects or damage. They then diagnose the problem and determine the best course of action. They can also provide troubleshooting tips and advice to prevent future problems.

- Inspect tools and equipment for wear and tear, damage, or defects.

- Diagnose problems with tools and equipment, and determine the best course of action.

2. Repair and Maintain

Tool Repairers repair and maintain tools and equipment by performing a variety of tasks, such as replacing parts, adjusting components, and calibrating equipment. They also perform preventive maintenance, such as cleaning and lubricating tools and equipment, to ensure that they are in optimal condition.

- Repair and maintain tools and equipment by replacing parts, adjusting components, and calibrating equipment.

- Perform preventive maintenance on tools and equipment, such as cleaning and lubricating, to ensure that they are in optimal condition.

3. Calibrate and Test

Tool Repairers calibrate and test tools and equipment to ensure that they are accurate and functioning properly. They also develop and implement calibration procedures to ensure that tools and equipment meet the required standards.

- Calibrate and test tools and equipment to ensure that they are accurate and functioning properly.

- Develop and implement calibration procedures to ensure that tools and equipment meet the required standards.

4. Troubleshoot

Tool Repairers troubleshoot problems with tools and equipment. They use their knowledge of the equipment and their troubleshooting skills to identify and resolve problems quickly and efficiently.

- Troubleshoot problems with tools and equipment.

- Use their knowledge of the equipment and their troubleshooting skills to identify and resolve problems quickly and efficiently.

Interview Tips

Interviewing for a job as a Tool Repairer can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go on an interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Tool Repairer. You can also use this information to tailor your answers to the interviewer’s questions.

- Visit the company’s website and read about their mission, values, and products or services.

- Look up the job description for the position you are applying for.

- Read reviews of the company on websites like Glassdoor and Indeed.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Think about your strengths and weaknesses, and how they relate to the job you are applying for.

- Prepare stories or examples that demonstrate your skills and abilities.

- Practice answering questions with a friend or family member.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience as a Tool Repairer. Be prepared to talk about your skills and abilities, and how they have helped you to be successful in your previous roles.

- Quantify your accomplishments whenever possible.

- Use specific examples to illustrate your skills and abilities.

- Be enthusiastic and positive when talking about your experience.

4. Ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your chance to learn more about the company and the position, and to show that you are interested in the job.

- Prepare a few questions to ask the interviewer.

- Questions about the company culture, the position, and the company’s goals are all good options.

- Asking questions shows that you are interested in the job and that you are engaged in the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.