Are you gearing up for an interview for a Tool Room Machinist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tool Room Machinist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

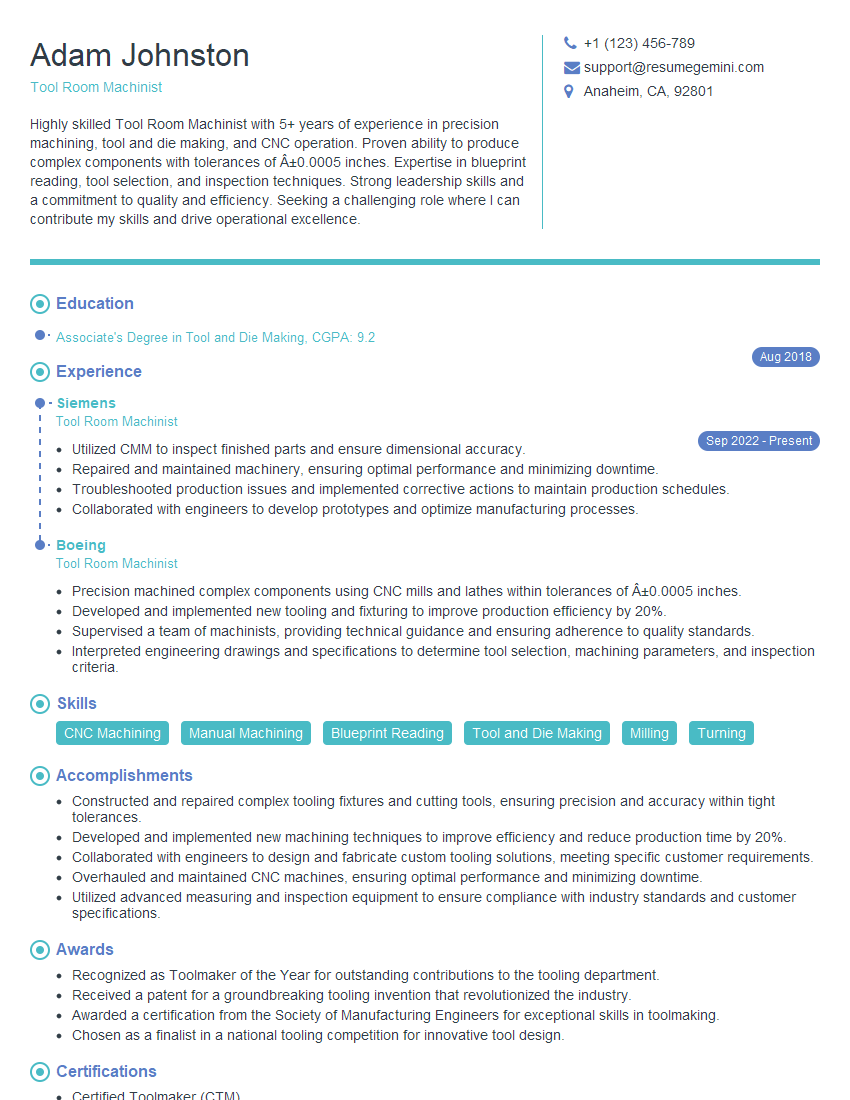

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Room Machinist

1. Can you explain the difference between a milling cutter and an end mill?

A milling cutter is a cutting tool with multiple cutting edges, used to remove material from the workpiece. An end mill is a type of milling cutter, used to cut in all directions around its axis of rotation.

- Milling cutters have multiple cutting edges, while end mills have only one.

- Milling cutters are mounted on a mandrel, while end mills are mounted on a collet.

- Milling cutters are used for a variety of operations, including surface milling, face milling, and slot milling. End mills are used for a variety of operations, including drilling, boring, and contouring.

2. What are the different types of cutting fluids and when would you use each type?

Straight oils

- Mineral oil-based

- Used for moderate to heavy-duty machining operations

- Provides good lubrication and cooling

Soluble oils

- Emulsified in water

- Used for light to medium-duty machining operations

- Provides good cooling and rust protection

Synthetic fluids

- Chemically engineered

- Used for high-performance machining operations

- Provides excellent lubrication and cooling

3. What are the advantages and disadvantages of using CNC machines?

Advantages

- Increased accuracy and precision

- Reduced setup times

- Increased productivity

- Reduced labor costs

Disadvantages

- High initial investment

- Requires skilled operators

- Can be complex to program

- Can be difficult to maintain

4. What are the different types of toolholders and when would you use each type?

Collets

- Used to hold round tools

- Provide good grip and accuracy

- Can be used for a variety of machining operations

Arbors

- Used to hold larger tools

- Provide good rigidity and support

- Can be used for a variety of machining operations

Chucks

- Used to hold irregular-shaped tools

- Provide good grip and versatility

- Can be used for a variety of machining operations

5. What are the different types of cutting tools and when would you use each type?

Cutting bits

- Made of hardened steel or carbide

- Used to remove material from the workpiece

- Come in a variety of shapes and sizes

Insertable cutters

- Made of hardened steel or carbide

- Can be replaced when worn

- Provide good economy and performance

Solid cutters

- Made of hardened steel or carbide

- Cannot be replaced when worn

- Provide good accuracy and precision

6. What are the different types of machining operations and when would you use each type?

Turning

- Used to create cylindrical or conical shapes

- Can be used to create a variety of features, such as shoulders, grooves, and threads

Milling

- Used to create flat or contoured surfaces

- Can be used to create a variety of features, such as pockets, slots, and gears

Drilling

- Used to create holes

- Can be used to create a variety of holes, such as straight holes, tapered holes, and blind holes

7. What are the different types of measurement tools and when would you use each type?

Dial indicators

- Used to measure small displacements

- Can be used to measure a variety of features, such as runout, parallelism, and flatness

Micrometers

- Used to measure small distances

- Can be used to measure a variety of features, such as length, diameter, and thickness

Calipers

- Used to measure larger distances

- Can be used to measure a variety of features, such as length, width, and height

8. What are the different types of inspection tools and when would you use each type?

Visual inspection

- Used to detect surface defects

- Can be used to inspect a variety of materials, such as metal, plastic, and wood

Dimensional inspection

- Used to measure the size and shape of a workpiece

- Can be used to inspect a variety of features, such as length, width, and height

Non-destructive testing

- Used to inspect the interior of a workpiece without damaging it

- Can be used to detect a variety of defects, such as cracks, voids, and inclusions

9. What are the different types of quality control methods and when would you use each type?

Statistical process control

- Used to monitor and control the quality of a manufacturing process

- Can be used to identify and correct problems before they occur

Acceptance sampling

- Used to determine whether a lot of product is acceptable

- Can be used to ensure that the quality of a product meets customer requirements

Total quality management

- Used to create a culture of quality throughout an organization

- Can be used to improve the quality of a product, service, or process

10. What are some of the challenges you have faced as a tool room machinist?

- Working with tight tolerances

- Meeting production deadlines

- Solving complex machining problems

- Staying up-to-date on new technologies

- Working with a variety of materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Room Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Room Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Room Machinists are responsible for the maintenance and repair of tools, dies, jigs, and fixtures used in manufacturing processes. They work closely with engineers and other production staff to ensure that the tools and equipment used on the production floor are in good working order and meet the required specifications.

1. Set up and operate machine tools

Tool Room Machinists set up and operate a variety of machine tools, including lathes, mills, grinders, and drill presses. They use these machines to create and repair tools, dies, jigs, and fixtures.

- Set up and operate machine tools to produce precision parts

- Inspect parts to ensure they meet specifications

2. Perform quality control checks

Tool Room Machinists perform quality control checks on the tools and equipment they produce. They use a variety of measuring tools and instruments to ensure that the tools meet the required specifications.

- Inspect tools and equipment to ensure they meet specifications

- Make adjustments to tools and equipment as needed

3. Maintain and repair tools and equipment

Tool Room Machinists maintain and repair the tools and equipment used in manufacturing processes. They clean, lubricate, and adjust tools and equipment to keep them in good working order.

- Clean, lubricate, and adjust tools and equipment

- Perform minor repairs on tools and equipment

4. Train apprentices and other employees

Tool Room Machinists may train apprentices and other employees on the use and maintenance of tools and equipment. They teach apprentices and other employees how to set up and operate machine tools, perform quality control checks, and maintain and repair tools and equipment.

- Train apprentices and other employees on the use and maintenance of tools and equipment

- Supervise apprentices and other employees

Interview Tips

There are a few things you can do to prepare for your Tool Room Machinist interview. First, make sure you have a strong understanding of the key job responsibilities and qualifications. You can do this by reading the job description and researching the company. Second, practice answering common interview questions. Here are a few examples:

1. Why are you interested in this position?

When answering this question, be sure to highlight your skills and experience that are relevant to the position. You can also mention your interest in the company and the industry.

- I am interested in this position because it aligns with my skills and experience in tool making and machining.

- I am also tertarik in the company’s commitment to quality and innovation.

2. What are your strengths and weaknesses?

When answering this question, be honest and self-aware. Focus on your strengths that are relevant to the position and how you can use them to benefit the company. As for your weaknesses, be prepared to discuss how you are working to improve them.

- My strengths include my attention to detail, my ability to work independently, and my strong work ethic.

- I am also a quick learner and I am always willing to take on new challenges.

3. What are your salary expectations?

When answering this question, be realistic and do your research. You can use online salary calculators or talk to a recruiter to get an idea of what the average salary is for this position in your area.

- My salary expectations are in line with the average salary for this position in my area.

- I am also willing to negotiate based on my experience and qualifications.

4. Do you have any questions for me?

This is your chance to ask the interviewer questions about the position and the company. Asking thoughtful questions shows that you are interested in the position and that you have done your research.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Room Machinist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Room Machinist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.