Feeling lost in a sea of interview questions? Landed that dream interview for Tool Room Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tool Room Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

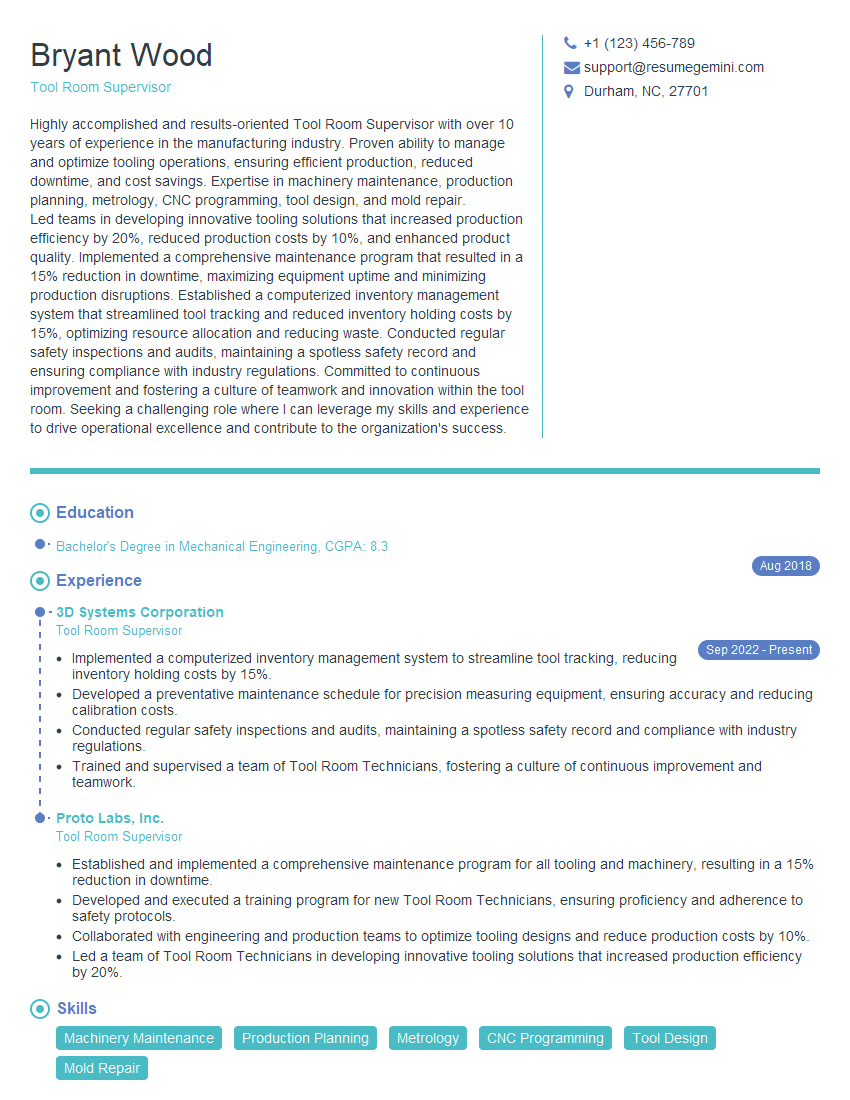

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Room Supervisor

1. Describe the key responsibilities of a Tool Room Supervisor.

The key responsibilities of a Tool Room Supervisor typically include:

- Supervising and managing the tool room staff, including toolmakers, machinists, and apprentices.

- Planning and scheduling tool room activities, including the production of new tools, the maintenance and repair of existing tools, and the calibration and inspection of tools.

- Ensuring that all tools are properly maintained and calibrated, and that they meet the required specifications.

- Developing and implementing quality control procedures for the tool room.

- Maintaining inventory of tools and supplies, and placing orders for new tools and supplies as needed.

- Training and developing tool room staff.

- Working with other departments, such as engineering and production, to ensure that the tool room is meeting their needs.

2. What are the different types of tools that are typically found in a tool room?

The types of tools that are typically found in a tool room can vary depending on the industry, but some of the most common types include:

- Cutting tools, such as drills, milling cutters, and taps.

- Forming tools, such as punches, dies, and molds.

- Measuring tools, such as calipers, micrometers, and gauges.

- Hand tools, such as wrenches, screwdrivers, and pliers.

- Power tools, such as drills, grinders, and saws.

- Inspection equipment, such as microscopes and CMMs.

3. What are the different types of materials that are used in toolmaking?

The types of materials that are used in toolmaking can vary depending on the application, but some of the most common types include:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

- Plastic

- Ceramics

4. What are the different processes that are used in toolmaking?

The processes that are used in toolmaking can vary depending on the type of tool being made, but some of the most common processes include:

- Milling

- Turning

- Grinding

- EDM (Electrical Discharge Machining)

- Wire EDM

- Heat treating

- Coating

5. What are the different types of quality control checks that are performed on tools?

The types of quality control checks that are performed on tools can vary depending on the type of tool, but some of the most common checks include:

- Visual inspection

- Dimensional inspection

- Hardness testing

- Coating thickness testing

- Functional testing

6. What are the different ways to improve tool life?

There are many ways to improve tool life, including:

- Using the correct tool for the job

- Using the correct cutting parameters

- Maintaining the tool properly

- Using coolants and lubricants

- Coating the tool

7. What are the different types of tool management systems?

There are many different types of tool management systems, including:

- Manual tool management systems

- Automated tool management systems

- Cloud-based tool management systems

8. What are the benefits of using a tool management system?

There are many benefits of using a tool management system, including:

- Reduced tooling costs

- Improved tool life

- Increased productivity

- Improved safety

- Reduced downtime

9. What are the different types of tool storage systems?

There are many different types of tool storage systems, including:

- Tool chests

- Tool cabinets

- Tool carts

- Wall-mounted tool storage systems

10. What are the different factors to consider when choosing a tool storage system?

The factors to consider when choosing a tool storage system include:

- The number of tools that need to be stored

- The size and weight of the tools

- The frequency of use of the tools

- The budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Room Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Room Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tool Room Supervisor is accountable for overseeing and organizing all aspects of a tool room within an organization. This encompasses the management of tools, machinery, and equipment, as well as supervising staff involved in the maintenance and repair of tools.

1. Tool Management

The Supervisor ensures the proper inventory and maintenance of all tools within the tool room.

- Establishing and implementing systems for tool storage, organization, and tracking.

- Conducting regular audits and inspections to monitor tool usage and identify any discrepancies.

2. Equipment Maintenance and Repair

The Supervisor supervises and monitors the maintenance and repair of all machinery and equipment within the tool room.

- Ensuring that all tools are regularly serviced and calibrated according to manufacturer specifications.

- Coordinating with vendors and service providers for repairs and replacement of damaged or obsolete tools.

3. Staff Supervision and Training

The Supervisor leads and manages a team of tool room staff, providing guidance and support.

- Training staff on proper tool handling, maintenance, and safety procedures.

- Setting performance goals, conducting evaluations, and providing feedback to staff.

4. Process Improvement

The Supervisor continuously reviews and evaluates tool room operations to identify areas for improvement.

- Implementing new technologies and best practices to enhance tool management and efficiency.

- Developing and implementing processes to reduce tool downtime and increase productivity.

Interview Tips

Here are some key interview tips to help candidates ace an interview for a Tool Room Supervisor position:

1. Research the Company and Role

Take the time to thoroughly research the company and the specific Tool Room Supervisor role.

- Familiarize yourself with the company’s history, products, services, and values.

- Identify the specific responsibilities and qualifications required for the role.

2. Highlight Relevant Experience

During the interview, emphasize your relevant experience that demonstrates your ability to fulfill the key job responsibilities.

- Provide specific examples of how you have managed tools, supervised staff, and implemented process improvements in previous roles.

- Quantify your accomplishments to demonstrate the impact of your work.

3. Showcase Leadership and Management Skills

Highlight your leadership and management skills, as these are essential for a Tool Room Supervisor.

- Describe how you have motivated and developed your team to achieve high performance.

- Provide examples of how you have resolved conflicts and made difficult decisions.

4. Technical Knowledge

Demonstrate your technical knowledge of tools, machinery, and equipment.

- Be prepared to discuss the types of tools and equipment commonly used in tool rooms.

- Show your understanding of tool maintenance and repair procedures.

5. Be Enthusiastic and Confident

Convey your enthusiasm for the role and your confidence in your abilities.

- Show the interviewer that you are passionate about tool management and supervision.

- Be confident in your skills and abilities, but be humble and willing to learn.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Room Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Room Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.