Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Salvage Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Salvage Worker so you can tailor your answers to impress potential employers.

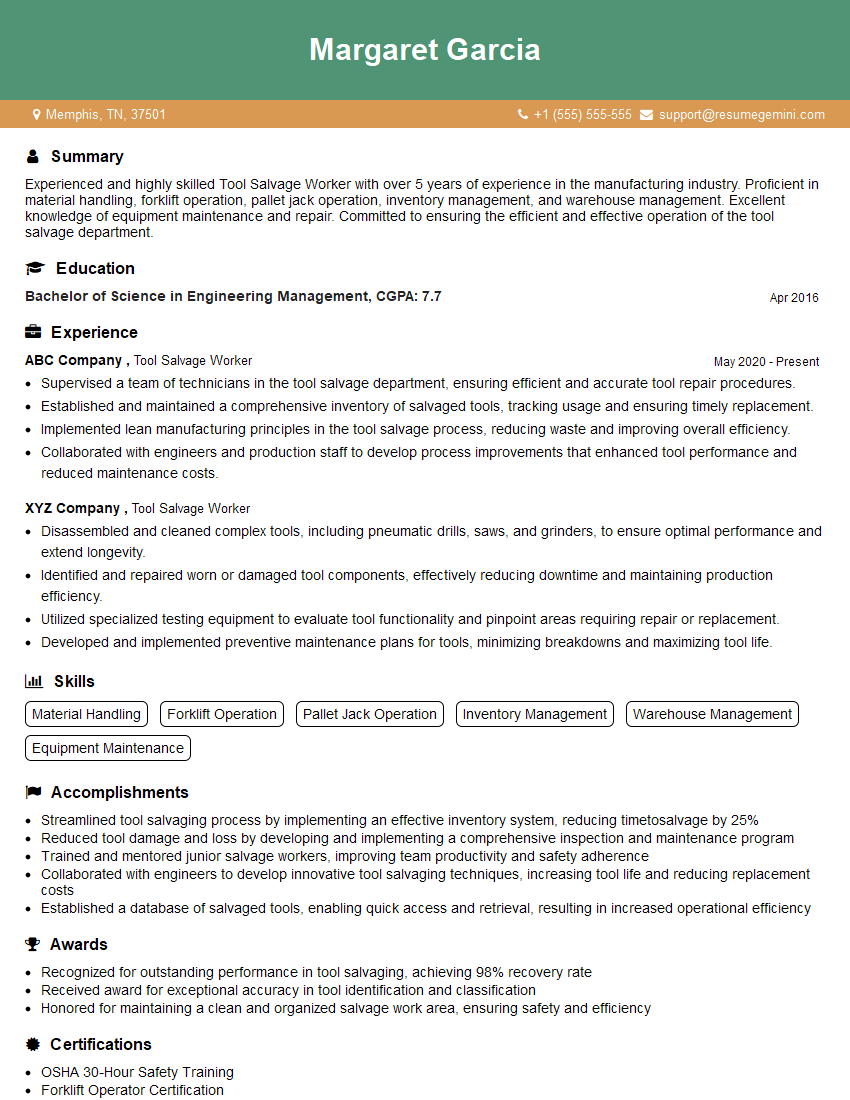

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Salvage Worker

1. What are the different types of tools that you have experience salvaging?

In my previous role, I was responsible for salvaging a wide range of tools, including:

- Hand tools (e.g., hammers, wrenches, screwdrivers)

- Power tools (e.g., drills, saws, grinders)

- Measuring tools (e.g., rulers, calipers, micrometers)

- Specialty tools (e.g., automotive tools, construction tools)

2. What is the process you follow when salvaging tools?

Identifying the tools

- Visually inspect tools to identify the type, make, and model.

- Check for any visible damage or defects.

Disassembling the tools

- Remove any bolts, screws, or other fasteners.

- Separate the different components of the tool.

- Clean and inspect each component.

Repairing the tools

- Identify any damaged or worn components.

- Replace or repair damaged components.

- Lubricate and adjust the tools as needed.

Reassembling the tools

- Reassemble the tools in the correct order.

- Tighten all bolts, screws, and other fasteners.

- Test the tools to ensure they are functioning properly.

3. What are some of the challenges you have encountered when salvaging tools?

One of the biggest challenges I have encountered is salvaging tools that are severely damaged or rusted. In these cases, I need to carefully assess the damage and determine if the tool is worth salvaging. Another challenge is salvaging tools that are made from specialty materials, such as titanium or stainless steel. These materials can be difficult to work with and require specialized tools.

4. What are some of the safety precautions you take when salvaging tools?

- Always wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Inspect tools carefully before using them to identify any potential hazards.

- Use the correct tools for the job and follow all safety instructions.

- Be aware of your surroundings and take precautions to avoid accidents.

- Never attempt to salvage a tool that is damaged or unsafe.

5. How do you stay up-to-date on the latest tool salvage techniques?

- Attend industry conferences and workshops.

- Read trade publications and online articles.

- Network with other tool salvage professionals.

- Seek out training opportunities from manufacturers and suppliers.

6. What are some of the trends you are seeing in the tool salvage industry?

- Increased use of automation and robotics in tool salvage operations.

- Development of new and innovative tool salvage techniques.

- Growing demand for sustainable tool salvage practices.

- Increased focus on safety and compliance.

7. How do you handle situations where you are unable to salvage a tool?

- First, I try to identify the reason why the tool cannot be salvaged.

- I then communicate this information to my supervisor and/or the customer.

- Together, we decide on the best course of action, such as recycling the tool or disposing of it properly.

8. What is your favorite part about being a Tool Salvage Worker?

My favorite part about being a Tool Salvage Worker is the challenge of taking something that is broken or damaged and restoring it to its original condition. I also enjoy the satisfaction of knowing that I am helping to extend the life of tools and reduce waste.

9. What are your career goals?

My career goal is to become a supervisor in the tool salvage industry. I would like to continue to develop my skills and knowledge, and eventually lead a team of tool salvage workers.

10. What are your strengths and weaknesses as a Tool Salvage Worker?

Strengths:

- Excellent technical skills

- Strong work ethic

- Attention to detail

- Problem-solving skills

- Teamwork skills

Weaknesses:

- Impatience

- Perfectionism

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Salvage Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Salvage Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Tool Salvage Worker is a crucial member of the maintenance team, responsible for salvaging and reconditioning tools and equipment to increase their lifespan and optimize operations.

1. Tool Reconditioning

Recondition and rebuild damaged or broken tools and equipment to extend their service life.

- Dismantle and inspect tools and equipment to assess the extent of damage.

- Repair or replace damaged components, such as bearings, springs, and seals.

2. Tool Inspection and Maintenance

Conduct regular inspections of tools and equipment to identify potential issues and prevent breakdowns.

- Inspect tools for signs of wear, damage, or malfunction.

- Perform preventive maintenance tasks, such as lubrication, cleaning, and calibration.

3. Data Management and Reporting

Maintain accurate records of tool reconditioning and maintenance activities for tracking and reporting purposes.

- Document tool repair and maintenance procedures and outcomes.

- Report on tool usage, condition, and any issues that require attention.

4. Collaboration and Communication

Collaborate with maintenance technicians and other stakeholders to identify tool and equipment needs.

- Consult with technicians to determine the cause of tool failures and develop solutions.

- Communicate tool reconditioning status and provide updates to stakeholders.

Interview Tips

Preparing for an interview for a Tool Salvage Worker position requires a combination of technical knowledge, situational awareness, and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Role and Company

Before the interview, thoroughly research the Tool Salvage Worker role and the company you are applying to. This will demonstrate your interest in the position and help you understand the specific requirements of the job.

- Review job descriptions and company websites to learn about the key responsibilities and expectations.

- Research the company’s industry, products, and services to familiarize yourself with their business.

2. Practice Responding to Common Interview Questions

Prepare for common interview questions by anticipating the types of questions that may be asked. Practice your responses to highlight your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

- Rehearse your answers with a friend, family member, or career counselor to improve your delivery and confidence.

3. Showcase Your Technical Skills and Knowledge

During the interview, emphasize your technical skills and knowledge in tool reconditioning, inspection, and maintenance. Provide examples of projects or tasks where you successfully salvaged or repaired tools and equipment.

- Highlight your understanding of different tool types and their functions.

- Discuss your expertise in diagnosing and troubleshooting tool issues.

4. Demonstrate Your Commitment to Safety and Quality

Tool Salvage Workers must prioritize safety and quality in their work. Emphasize your commitment to following safety protocols and adhering to quality standards in your interview.

- Explain your understanding of industry safety regulations and how you ensure compliance.

- Discuss your attention to detail and your ability to produce high-quality work.

5. Highlight Your Communication and Interpersonal Skills

Effective communication and interpersonal skills are essential for Tool Salvage Workers who interact with technicians, supervisors, and other stakeholders. Demonstrate your ability to communicate clearly and collaborate effectively.

- Provide examples of how you effectively communicated with technicians to resolve tool issues.

- Discuss your experience in working as part of a team and your ability to build relationships with colleagues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Salvage Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!