Are you gearing up for a career in Tool Setter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tool Setter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

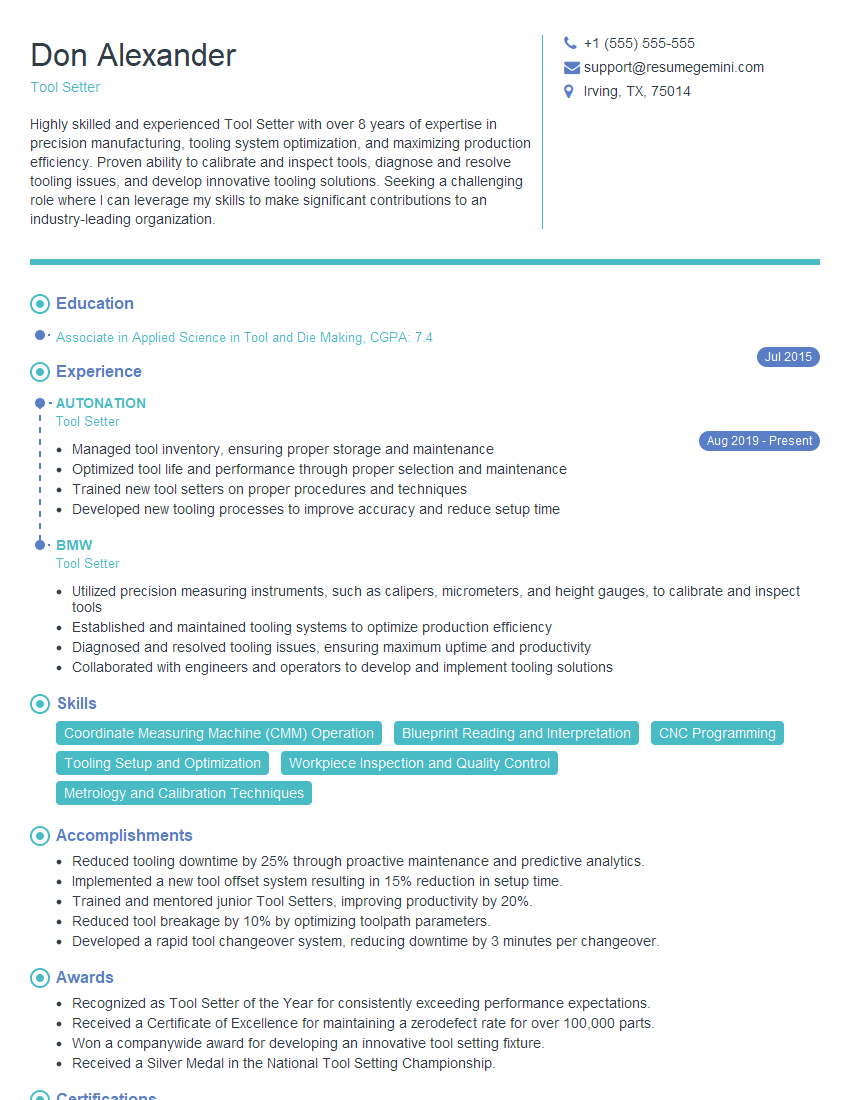

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Setter

1. How would you align a new tool on a CNC machine?

To align a new tool on a CNC machine, I would follow these steps:

- Mount the tool in the tool holder.

- Jog the machine to the tool change position.

- Use the tool setter to measure the tool length and offset.

- Enter the tool length and offset into the CNC program.

- Run the program to test the tool alignment.

2. What is the difference between a tool setter and a touch probe?

A tool setter is used to measure the length and offset of a tool, while a touch probe is used to measure the position of a workpiece. Tool setters are typically more accurate than touch probes, but they can only be used to measure tools. Touch probes can be used to measure both tools and workpieces, but they are not as accurate as tool setters.

3. What are the different types of tool setters?

There are many different types of tool setters, but the most common types are:

- Contact tool setters

- Non-contact tool setters

- Laser tool setters

Contact tool setters use a physical probe to measure the tool length and offset. Non-contact tool setters use a laser or other non-contact sensor to measure the tool length and offset. Laser tool setters use a laser to measure the tool length and offset.

4. How do you calibrate a tool setter?

To calibrate a tool setter, you will need to follow the manufacturer’s instructions. In general, you will need to use a known tool length to set the zero point of the tool setter. Once the zero point has been set, you can then use the tool setter to measure the length and offset of other tools.

5. What are the benefits of using a tool setter?

Using a tool setter has many benefits, including:

- Reduced setup time

- Improved accuracy

- Increased productivity

- Reduced scrap

Tool setters can help to reduce setup time by eliminating the need to manually measure the length and offset of tools. They can also help to improve accuracy by providing a more precise measurement of the tool length and offset. This can lead to increased productivity and reduced scrap.

6. What are the challenges of using a tool setter?

There are some challenges associated with using a tool setter, including:

- Cost

- Complexity

- Maintenance

Tool setters can be expensive to purchase and maintain. They can also be complex to use and require specialized training. However, the benefits of using a tool setter often outweigh the challenges.

7. How do you troubleshoot a tool setter?

If you are experiencing problems with a tool setter, there are a few things you can do to troubleshoot the problem:

- Check the power supply.

- Check the connections.

- Check the calibration.

- Contact the manufacturer.

8. What are some tips for using a tool setter effectively?

Here are some tips for using a tool setter effectively:

- Use the tool setter regularly.

- Keep the tool setter clean.

- Calibrate the tool setter regularly.

- Follow the manufacturer’s instructions.

9. What is the most important thing to remember when using a tool setter?

The most important thing to remember when using a tool setter is to follow the manufacturer’s instructions.

10. What are some of the latest trends in tool setting technology?

Some of the latest trends in tool setting technology include:

- Increased use of automation

- Development of new sensor technologies

- Integration of tool setting with other manufacturing processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tool Setter is responsible for ensuring that the tools used in a manufacturing process are properly set up and maintained. This can involve a variety of tasks, including:

1. Installing and calibrating tools

Tool Setters must be able to install and calibrate tools according to the manufacturer’s specifications. This may involve using a variety of tools, such as wrenches, screwdrivers, and gauges.

- Example: A Tool Setter might be responsible for installing a new cutting tool on a milling machine.

2. Inspecting and maintaining tools

Tool Setters must also inspect and maintain tools on a regular basis. This may involve checking for wear and tear, and making repairs or adjustments as needed.

- Example: A Tool Setter might be responsible for inspecting a drill bit for wear and tear, and replacing it if necessary.

3. Troubleshooting and repairing tools

When tools malfunction, Tool Setters are responsible for troubleshooting and repairing them. This may involve identifying the source of the problem and making the necessary repairs.

- Example: A Tool Setter might be responsible for troubleshooting a cutting tool that is not cutting properly.

4. Providing training to other employees

Tool Setters may also be responsible for providing training to other employees on the proper use and maintenance of tools.

- Example: A Tool Setter might be responsible for training a new employee on how to use a milling machine.

Interview Tips

In order to ace an interview for a Tool Setter position, it is important to be prepared to answer questions about your skills and experience. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Example: You can visit the company’s website to learn more about its history, products, and services.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Example: You can practice your answers to these questions with a friend or family member.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience as a Tool Setter. Be prepared to talk about your experience setting up, calibrating, inspecting, and maintaining tools. You should also be prepared to talk about any troubleshooting or repair work that you have done.

- Example: You can prepare for this by writing down a list of your skills and experience, and then practicing talking about them.

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer.

- Example: You can show your enthusiasm by asking questions about the company and the position, and by sharing your ideas about how you can contribute to the company’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.