Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Straightener interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Straightener so you can tailor your answers to impress potential employers.

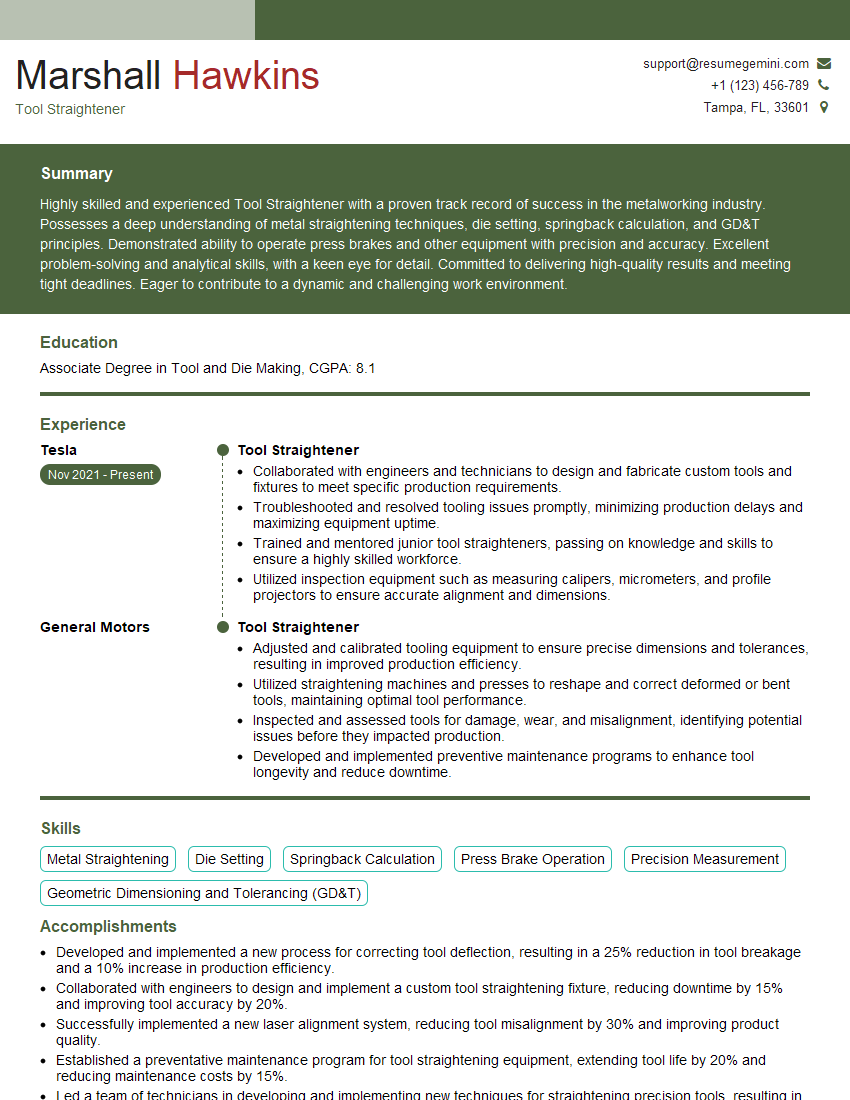

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Straightener

1. Explain the procedure of how to straighten a tool using a straightening jig?

- Inspect the tool for damage or wear.

- Select the appropriate straightening jig for the tool.

- Secure the tool in the jig.

- Apply pressure to the tool until it is straight.

- Check the tool for straightness using a precision measuring tool.

2. What are the different types of straightening jigs?

- Mechanical jigs

- Hydraulic jigs

- Pneumatic jigs

3. What are the factors that affect the accuracy of a straightening operation?

- The condition of the tool

- The type of straightening jig

- The amount of pressure applied

- The skill of the operator

4. What are the safety precautions that should be taken when straightening a tool?

- Wear safety glasses.

- Use gloves to protect your hands.

- Secure the tool in the jig properly.

- Do not apply excessive pressure to the tool.

- Inspect the tool for damage after straightening.

5. What are the common problems that can occur when straightening a tool?

- The tool may not be straight after straightening.

- The tool may be damaged during straightening.

- The straightening jig may not be working properly.

6. How do you troubleshoot a straightening jig that is not working properly?

- Inspect the jig for damage.

- Check the hydraulic or pneumatic system for leaks.

- Calibrate the jig using a precision measuring tool.

7. What are the different types of tools that can be straightened?

- Hand tools

- Power tools

- Cutting tools

- Measuring tools

8. What is the importance of straightening tools?

- Straight tools are more accurate.

- Straight tools are more durable.

- Straight tools are safer to use.

9. What are the different methods of straightening tools?

- Mechanical straightening

- Hydraulic straightening

- Pneumatic straightening

10. What are the advantages and disadvantages of different straightening methods?

Mechanical straightening

- Advantages: Simple and inexpensive.

- Disadvantages: Not as accurate as other methods.

Hydraulic straightening

- Advantages: Accurate and powerful.

- Disadvantages: More expensive than mechanical straightening.

Pneumatic straightening

- Advantages: Fast and portable.

- Disadvantages: Not as accurate as hydraulic straightening.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Straighteners are responsible for ensuring the precision and accuracy of tools used in various industries. Their key job responsibilities include:

1. Tool Inspection

Inspecting and assessing tools for defects, wear and tear, and any deviations from specifications.

- Using precision measuring instruments to verify dimensions, angles, and tolerances

- Identifying and documenting any discrepancies or non-conformances

2. Tool Adjustment and Repair

Adjusting and repairing tools to meet required specifications.

- Using specialized equipment and techniques to bend, straighten, and contour tools

- Replacing or repairing damaged tool components, such as blades, cutters, and inserts

3. Quality Control

Ensuring that tools meet established quality standards.

- Conducting quality checks and inspections throughout the straightening and repair process

- Documenting and maintaining records of tool inspections and repairs

4. Troubleshooting

Diagnosing and resolving tool-related issues.

- Troubleshooting and identifying the root causes of tool failures or malfunctions

- Providing guidance and technical support to operators and technicians

Interview Tips

Preparing for a Tool Straightener interview requires understanding the job responsibilities and demonstrating your skills and experience. Here are some tips:

1. Research the Company and Industry

Research the company you are applying to, as well as the industry in which they operate. This will give you a good understanding of the company’s culture, values, and the specific requirements of the role.

- Visit the company website and read about their mission, products, and services.

- Explore industry publications and websites to stay updated on the latest trends and advancements.

2. Highlight Your Technical Skills

Employers seek candidates with strong technical skills in tool straightening and repair. Emphasize your expertise in the following areas:

- Tool inspection and measurement

- Tool adjustment and alignment

- Tool repair and maintenance

- Troubleshooting and problem-solving

3. Showcase Your Quality Consciousness

Tool Straighteners play a crucial role in maintaining quality standards. Highlight your commitment to quality and accuracy by providing examples of your quality control practices and your attention to detail.

- Describe your experience in implementing quality control measures.

- Explain how you ensure that tools meet the required specifications.

4. Prepare for Common Interview Questions

Research common interview questions and prepare your answers to showcase your skills and experience. Some frequently asked questions include:

- Tell me about your experience in tool straightening and repair.

- How do you ensure that tools meet the required specifications?

- Give me an example of a time when you troubleshooted and resolved a tool-related issue.

- What are your strengths and weaknesses as a Tool Straightener?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Straightener role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.