Are you gearing up for a career in Tool Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tool Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

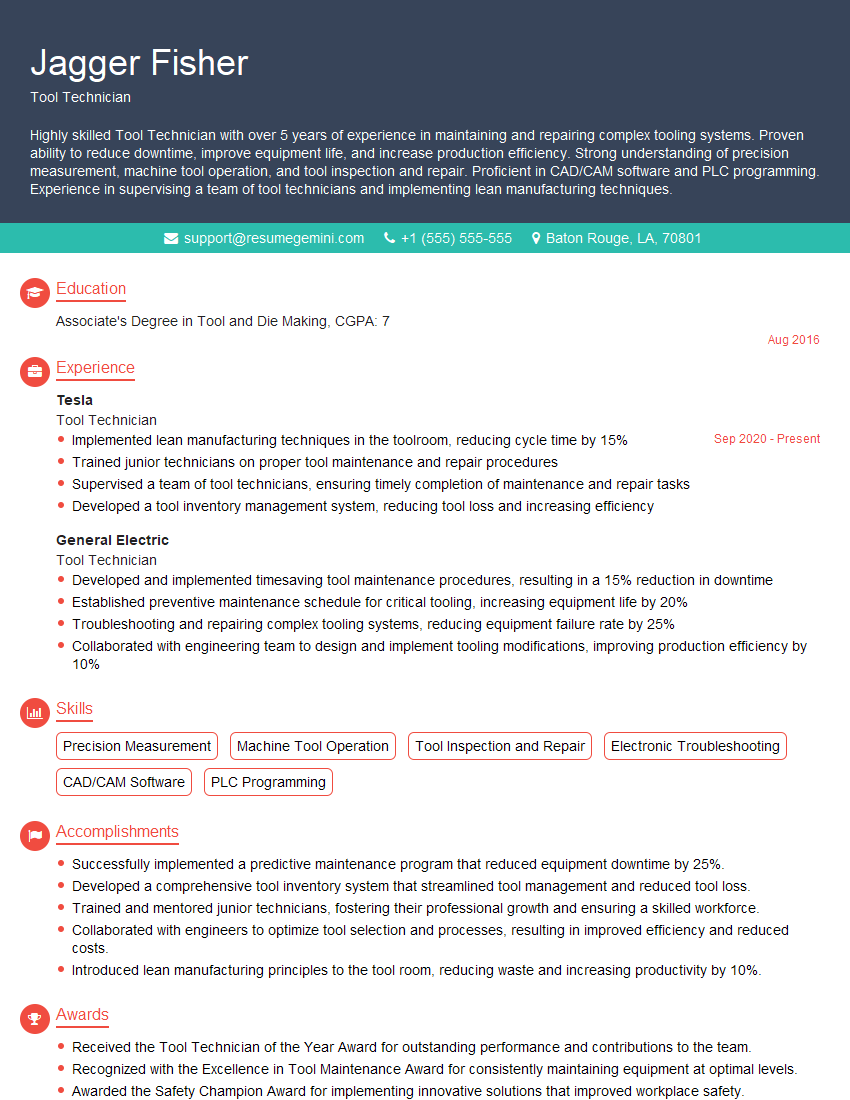

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Technician

1. What are the different types of tools that you are familiar with?

I am familiar with a wide variety of tools, including:

- Hand tools, such as screwdrivers, wrenches, pliers, and hammers

- Power tools, such as drills, saws, and grinders

- Precision tools, such as calipers, micrometers, and bore gauges

- Measuring tools, such as rulers, tape measures, and levels

- Machine tools, such as lathes, mills, and grinders

2. What are the safety procedures that you follow when using tools?

General Safety Procedures

- Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Never use a tool that you are not familiar with.

- Always inspect your tools for damage before using them.

- Never use a tool that is damaged.

- Always use tools in a well-ventilated area.

- Never use tools near flammable materials.

- Always store tools in a safe place when they are not in use.

Specific Safety Procedures

- When using hand tools, always use the correct tool for the job.

- When using power tools, always follow the manufacturer’s instructions.

- When using precision tools, always handle them with care.

- When using measuring tools, always check the accuracy of the tool before using it.

- When using machine tools, always follow the manufacturer’s instructions and never operate a machine without proper training.

3. What are the different types of materials that you have experience working with?

I have experience working with a wide variety of materials, including:

- Metals, such as steel, aluminum, and brass

- Plastics, such as ABS, PVC, and polyethylene

- Wood, such as pine, oak, and maple

- Glass

- Ceramics

4. What are the different types of machines that you have experience operating?

I have experience operating a wide variety of machines, including:

- Lathes

- Mills

- Grinders

- Drills

- Saws

- CNC machines

5. What are the different types of welding that you are familiar with?

I am familiar with a wide variety of welding processes, including:

- Arc welding

- MIG welding

- TIG welding

- Oxy-fuel welding

- Laser welding

6. What are the different types of maintenance that you have experience performing on tools and machines?

I have experience performing a wide variety of maintenance tasks on tools and machines, including:

- Preventive maintenance, such as lubrication, cleaning, and inspection

- Corrective maintenance, such as replacing worn parts and repairing damaged equipment

- Overhaul, such as completely disassembling and rebuilding a machine

7. What are the troubleshooting skills that you have?

I have a strong troubleshooting ability and I am able to quickly identify and resolve problems.

- I start by gathering information about the problem, such as when it started, what symptoms it is causing, and what steps have been taken to try to resolve it.

- I then use my knowledge of tools and machines to identify the possible causes of the problem.

- Once I have identified the possible causes of the problem, I develop and test solutions.

- I continue to test solutions until I have found one that resolves the problem.

8. What are the communication skills that you have?

I have strong communication skills and I am able to clearly and concisely communicate with people from all walks of life.

- I am able to write clear and concise reports, emails, and other documents.

- I am able to give clear and concise presentations.

- I am able to effectively communicate with people from all cultures and backgrounds.

9. What are the teamwork skills that you have?

I am a team player and I am able to work effectively with others to achieve a common goal.

- I am able to share my ideas and knowledge with others.

- I am able to listen to and understand the ideas of others.

- I am able to compromise and work towards a consensus.

- I am able to motivate and inspire others.

10. What are your career goals?

My career goal is to become a Tool Technician Supervisor. I am confident that I have the skills and experience necessary to be successful in this role.

- I am a highly motivated and results-oriented individual.

- I am a team player and I am able to work effectively with others to achieve a common goal.

- I am a lifelong learner and I am always looking for ways to improve my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Technicians play a crucial role in maintaining the smooth functioning of manufacturing and industrial operations. Their primary responsibilities include:

1. Equipment Maintenance and Repair

Inspect and maintain tools, equipment, and machinery to ensure optimal performance.

- Diagnose and troubleshoot mechanical and electrical issues.

- Repair or replace faulty components.

2. Tool Calibration and Inspection

Calibrate and inspect tools and equipment to ensure accuracy and compliance with industry standards.

- Use specialized gauges and testing equipment.

- Maintain documentation and records of calibration and inspections.

3. Preventive Maintenance

Conduct regular preventive maintenance tasks to minimize equipment downtime and extend the lifespan of tools.

- Clean and lubricate equipment.

- Replace worn or damaged parts.

4. Tool and Equipment Inventory Management

Maintain an inventory of tools and equipment, ensuring availability and tracking their usage.

- Order new tools and equipment as needed.

- Control and manage tool crib.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Tool Technician interview:

1. Research the Company and Position

Before the interview, take the time to research the company’s industry, products or services, and specific job requirements. This will help you understand their needs and demonstrate your enthusiasm for the role.

2. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to ensure they are clear, concise, and highlight your relevant skills and experience.

3. Showcase Your Technical Expertise

Emphasize your knowledge of tools, equipment, and machinery. Provide specific examples of your experience in diagnosing and repairing mechanical and electrical issues. Mention any certifications or training you have completed.

4. Highlight Your Organizational Skills

Tool Technicians must be highly organized and efficient. Discuss your experience in inventory management, preventive maintenance, and keeping detailed records. Explain how you ensure the availability and proper use of tools and equipment.

5. Be Prepared for Practical Tests

Some interviews may include practical tests or assessments. Be ready to demonstrate your skills in tool repair, calibration, or preventive maintenance. If possible, bring your own tools or request the necessary equipment beforehand.

6. Ask Thoughtful Questions

Asking informed questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s future plans, training opportunities, or specific tool-related challenges.

7. Follow Up

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and briefly highlight your key qualifications. This gesture can leave a positive impression and show your appreciation for the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!