Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Trouble Shooter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Trouble Shooter so you can tailor your answers to impress potential employers.

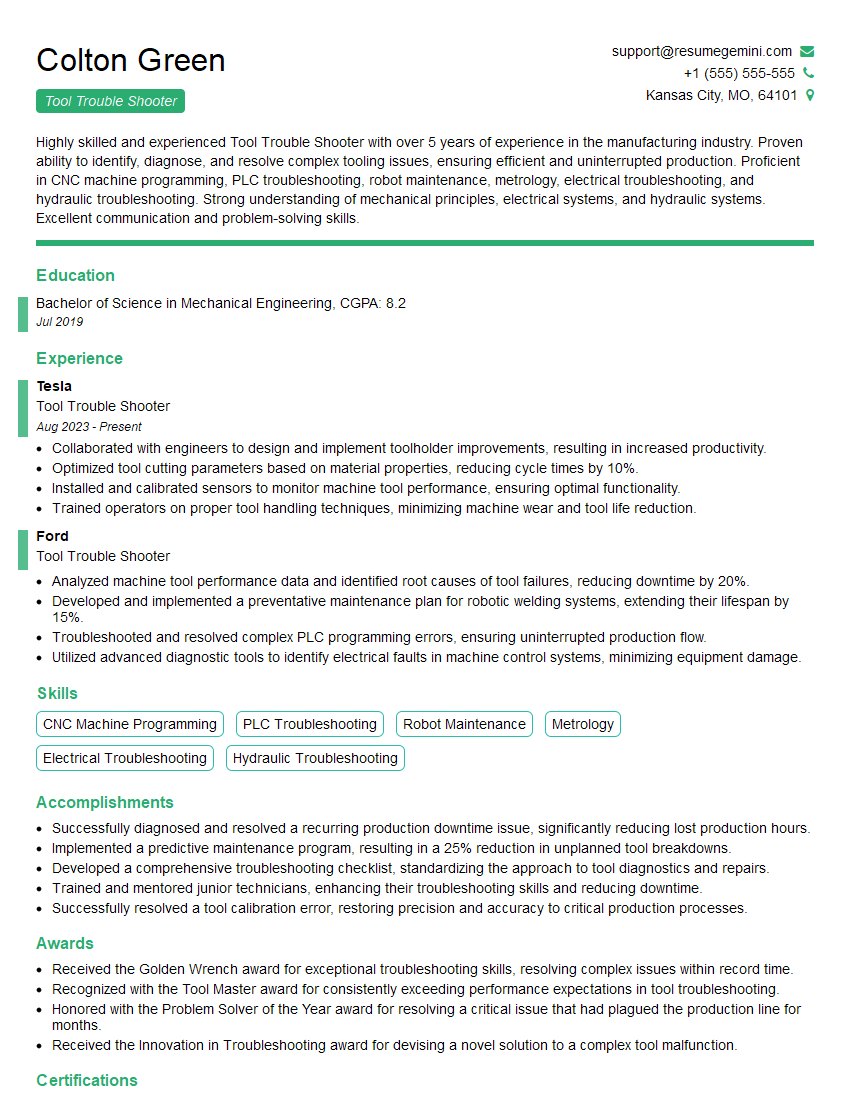

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Trouble Shooter

1. What are the common causes of tool failures?

The common causes of tool failures are:

- Improper maintenance

- Overheating

- Overloading

- Accidents

- Manufacturing defects

2. What are the steps involved in troubleshooting a tool failure?

Inspection

- Visually inspect the tool for any obvious damage, such as cracks, breaks, or loose connections.

- Check the tool’s power source to ensure that it is properly connected and supplying power.

Testing

- Test the tool’s functions to determine the nature of the failure.

- Compare the tool’s performance to its specifications to identify any deviations.

Repair

- Identify the cause of the failure and determine the appropriate repair.

- Repair or replace the damaged components.

3. What are the different types of tool failures?

The different types of tool failures include:

- Mechanical failures: These are caused by physical damage to the tool, such as a broken gear or a worn-out bearing.

- Electrical failures: These are caused by problems with the tool’s electrical system, such as a short circuit or a faulty motor.

- Software failures: These are caused by problems with the tool’s software, such as a bug or a virus.

4. What are the safety precautions that should be taken when troubleshooting tool failures?

The safety precautions that should be taken when troubleshooting tool failures include:

- Always wear appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection.

- Never attempt to repair a tool that is still connected to a power source.

- Be aware of the potential hazards associated with the tool, such as sharp edges or moving parts.

- Follow the manufacturer’s instructions for troubleshooting and repair.

5. What are the common tools and equipment used for troubleshooting tool failures?

The common tools and equipment used for troubleshooting tool failures include:

- Multimeter

- Oscilloscope

- Logic analyzer

- Soldering iron

- Replacement parts

6. What are the different types of tools used in manufacturing?

The different types of tools used in manufacturing include:

- Cutting tools: These tools are used to cut or shape materials, such as drills, saws, and milling cutters.

- Forming tools: These tools are used to shape or bend materials, such as presses, brakes, and rollers.

- Joining tools: These tools are used to join materials together, such as welders, soldering irons, and adhesives.

- Measuring tools: These tools are used to measure the dimensions of materials or objects, such as rulers, calipers, and micrometers.

7. What are the different types of tool materials?

The different types of tool materials include:

- Carbon steel: This is a low-cost and versatile material that is used for a wide range of applications.

- Alloy steel: This is a stronger and more durable material than carbon steel, and it is often used for cutting tools.

- High-speed steel: This is a very hard and wear-resistant material that is used for high-speed cutting operations.

- Carbide: This is an extremely hard and wear-resistant material that is used for cutting tools and other applications where high durability is required.

8. What are the different types of tool coatings?

The different types of tool coatings include:

- Titanium nitride (TiN): This is a hard and wear-resistant coating that is used to improve the performance of cutting tools.

- Titanium carbonitride (TiCN): This is a harder and more wear-resistant coating than TiN, and it is used for cutting tools that are subjected to high wear.

- Diamond-like carbon (DLC): This is a very hard and wear-resistant coating that is used for cutting tools that are used in extreme conditions.

9. What are the different types of tool sharpening?

The different types of tool sharpening include:

- Grinding: This is a process of removing material from a tool using a grinding wheel.

- Honing: This is a process of refining the edge of a tool using a honing stone.

- Lapping: This is a process of polishing the edge of a tool using a lapping compound.

10. What are the benefits of using a tool management system?

The benefits of using a tool management system include:

- Improved tool organization and inventory control

- Reduced tool costs

- Increased tool life

- Improved productivity

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Trouble Shooter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Trouble Shooter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Trouble Shooters are responsible for maintaining and repairing tools and equipment used in various industrial and manufacturing settings. They diagnose and resolve issues with machinery, ensuring that production processes run smoothly and efficiently.

1. Troubleshooting and Repair

Diagnose and repair a wide range of tools and equipment, including power tools, machinery, and diagnostic equipment.

- Identify mechanical, electrical, and software problems

- Determine the root cause of malfunctions

- Repair or replace faulty components

- Calibrate and adjust equipment to ensure optimal performance

2. Maintenance and Inspection

Perform regular maintenance and inspections to prevent breakdowns and ensure optimal performance of equipment.

- Inspect tools and equipment for wear, damage, or defects

- Lubricate and clean machinery

- Replace worn or damaged components

- Ensure equipment meets safety standards and regulations

3. Technical Support

Provide technical support to operators and other staff to resolve equipment-related issues.

- Respond to inquiries and troubleshoot problems over the phone or email

- Provide guidance on equipment operation and maintenance

- Document and report on equipment performance

4. Inventory Management

Maintain an inventory of tools, spare parts, and supplies.

- Order and receive inventory items

- Manage inventory levels to ensure availability

- Dispose of obsolete or damaged items

Interview Tips

To impress the hiring manager and ace your interview, here are some tips and preparation hacks:

1. Research the Company and Position

Before the interview, take time to research the company, its industry, and the specific role you’re applying for. This will help you understand the company’s culture, goals, and the specific requirements of the job.

- Visit the company’s website and read about their mission, values, and recent news.

- Check out the company’s LinkedIn page to learn more about their team and culture.

- Review the job description carefully and identify the key skills and experiences they’re looking for.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your relevant skills, experiences, and accomplishments.

- Quantify your results with specific numbers and metrics whenever possible.

3. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you a chance to learn more about the company and the role.

- Ask about the company’s growth plans and industry outlook.

- Inquire about opportunities for professional development and training.

- Ask about the company’s culture and work-life balance.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress appropriately for the interview. Arrive on time to show that you’re respectful of the interviewer’s time.

- Choose clean, pressed business attire.

- Avoid wearing strong scents or excessive jewelry.

- Plan your route in advance and allow extra time for unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Trouble Shooter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!