Are you gearing up for a career in Tooling Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tooling Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

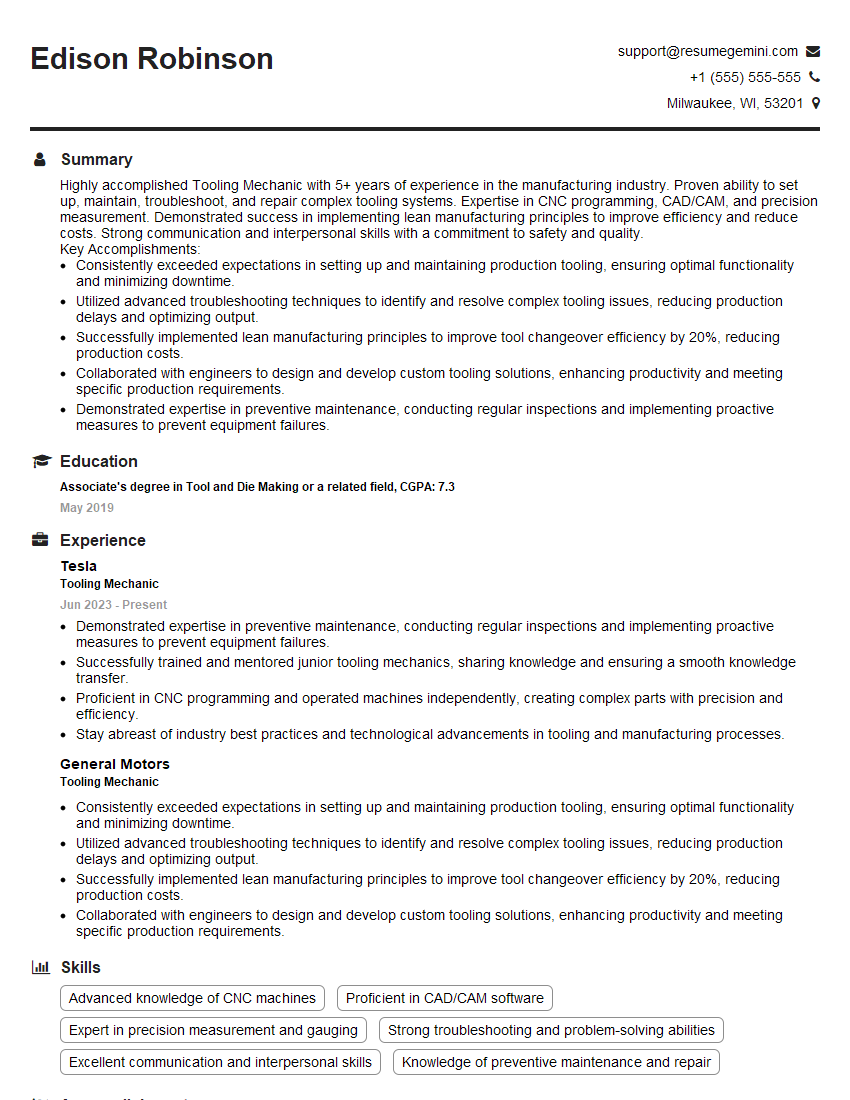

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tooling Mechanic

1. Describe the steps involved in setting up a precision measuring tool, such as a coordinate measuring machine (CMM)?

- Prepare the CMM by cleaning the work surface and ensuring that all necessary components are present.

- Install the workpiece on the CMM bed and align it using the appropriate fixtures.

- Calibrate the CMM using a standard reference artifact to ensure measurement accuracy.

- Define the coordinate system and establish the measurement points on the workpiece using the CMM software.

- Execute the measurement program and collect the necessary data.

2. What types of cutting fluids are commonly used in machining operations, and how do you select the appropriate fluid for a specific application?

Factors influencing the selection of cutting fluid include:

- Type of machining operation

- Material of the workpiece and cutting tool

- Desired surface finish

- Environmental regulations

Common types of cutting fluids:

- Straight oils: Mineral oil-based, suitable for low-speed operations on soft materials.

- Soluble oils: Oil-in-water emulsions, providing cooling and lubrication for moderate-speed operations.

- Synthetic fluids: Chemically engineered fluids, offering high performance and extended tool life.

- Semisynthetic fluids: Combinations of mineral oil and synthetic fluids, providing a balance of properties.

3. Explain the principles of pressworking and describe the different types of presses used in this process.

Pressworking involves forming sheet metal into desired shapes using pressure applied by a press.

Types of presses:

- Mechanical presses: Use a mechanical flywheel to generate force, providing high power and speed.

- Hydraulic presses: Utilize hydraulic fluid to apply pressure, offering precise control and slow, powerful strokes.

- Pneumatic presses: Use compressed air to generate force, suitable for small-scale operations and delicate materials.

4. How do you maintain and calibrate measuring equipment, such as micrometers and dial indicators, to ensure accuracy and reliability?

- Regularly clean and inspect equipment for damage or wear.

- Follow manufacturer’s instructions for calibration using standard reference gauges.

- Maintain a calibration log and track calibration intervals.

- Use calibrated equipment only for intended measurements.

5. What safety precautions should be observed when working with high-pressure hydraulic systems?

- Wear appropriate personal protective equipment (PPE), including gloves and eye protection.

- Inspect hydraulic lines and fittings regularly for leaks or damage.

- Never attempt to release pressure without proper training and authorization.

- Use only authorized tools and equipment for servicing or repairs.

- Be aware of the location of emergency shut-off valves.

6. Describe the different types of welding processes and explain their advantages and disadvantages.

Welding processes include:

- Arc welding: Uses an electric arc to melt and fuse metals, offering high strength and efficiency.

- Gas welding: Combines a fuel gas and oxygen to produce a flame for welding, providing versatility and portability.

- Resistance welding: Uses pressure and electric current to create a weld, offering high speed and automation.

Advantages and disadvantages:

- Arc welding: High strength, efficiency, but requires skilled operators and can produce fumes.

- Gas welding: Versatile, portable, but slower and requires precise gas control.

- Resistance welding: High speed, automation, but limited to certain materials and joint configurations.

7. How would you troubleshoot a CNC machine that is producing inaccurate parts?

- Check for mechanical errors, such as loose components or worn belts.

- Verify that the CNC program is correct and free of errors.

- Inspect the cutting tools for wear or damage.

- Examine the workpiece setup to ensure proper alignment and clamping.

- Review the tool offsets and work coordinate system.

8. Explain the importance of preventative maintenance in a tooling department and describe the steps involved in a typical preventative maintenance program.

- Importance: Prevents equipment failures, extends tool life, improves productivity, and ensures safety. Steps:

- Establish a regular maintenance schedule.

- Inspect and clean equipment regularly.

- Replace or repair worn or damaged components.

- Calibrate measuring instruments.

- Monitor equipment performance and keep maintenance records.

9. Discuss the different types of cutting tools used in machining operations and their applications.

Types of cutting tools:

- Single-point tools: Used for turning, facing, and boring operations.

- Multi-point tools: Used for milling, drilling, and reaming operations.

- Abrasive tools: Used for grinding, honing, and lapping operations.

Applications:

- Single-point tools: Precision cutting and forming of metals.

- Multi-point tools: High-volume production of complex shapes and features.

- Abrasive tools: Finishing and shaping of hard materials.

10. Describe the typical career progression path for a Tooling Mechanic.

- Apprentice Tooling Mechanic: Assists senior mechanics with basic tasks and receives training.

- Journeyman Tooling Mechanic: Performs a wide range of tooling maintenance and repair tasks.

- Senior Tooling Mechanic: Supervises junior mechanics and provides technical guidance.

- Tooling Supervisor: Manages the tooling department and ensures efficient operations.

- Tooling Manager: Responsible for the overall tooling strategy and development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tooling Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tooling Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tooling Mechanics are responsible for maintaining and repairing the tools and equipment used in a variety of industries, including manufacturing, automotive, and construction. They work closely with engineers and other technicians to ensure that the tools and equipment are operating properly and efficiently.

1. Inspect and maintain tools and equipment

Tooling Mechanics inspect and maintain a variety of tools and equipment, including:

- Machine tools

- Hand tools

- Power tools

- Welding equipment

- Hydraulic equipment

They perform regular maintenance tasks, such as cleaning, lubrication, and adjustments. They also troubleshoot and repair any problems that arise.

2. Install and repair tooling

Tooling Mechanics install and repair tooling on a variety of machines. This includes:

- Cutting tools

- Forming tools

- Punching tools

- Bending tools

- Welding tools

They ensure that the tooling is properly aligned and calibrated. They also troubleshoot and repair any problems that arise.

3. Build and modify jigs and fixtures

Tooling Mechanics build and modify jigs and fixtures. Jigs and fixtures are devices that are used to hold or position workpieces during manufacturing processes. They ensure that the workpieces are properly aligned and held in place.

4. Train operators on proper tool use

Tooling Mechanics train operators on the proper use of tools and equipment. This includes:

- How to use the tools safely

- How to maintain the tools properly

- How to troubleshoot and repair common problems

They also provide ongoing support to operators, answering questions and helping them to resolve any problems that they encounter.

Interview Tips

Preparing for an interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it’s important to research the company and the position you’re applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

You can research the company on its website, Glassdoor, and other online resources. You can also learn about the position by reading the job description and talking to people in your network who work in similar roles.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as:

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your career goals?

It’s helpful to practice answering these questions in advance. This will help you to feel more confident and prepared during the interview.

3. Prepare questions to ask the interviewer

Asking questions at the end of an interview is a great way to show that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the role.

Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What are the opportunities for advancement within the company?

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early.

Dressing professionally shows that you respect the interviewer and the company. Arriving on time shows that you’re organized and punctual.

5. Be yourself and stay positive

The most important thing is to be yourself and stay positive during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Stay positive, even if you’re nervous. A positive attitude can make a big impression on the interviewer.

Next Step:

Now that you’re armed with the knowledge of Tooling Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tooling Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini