Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tooling Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

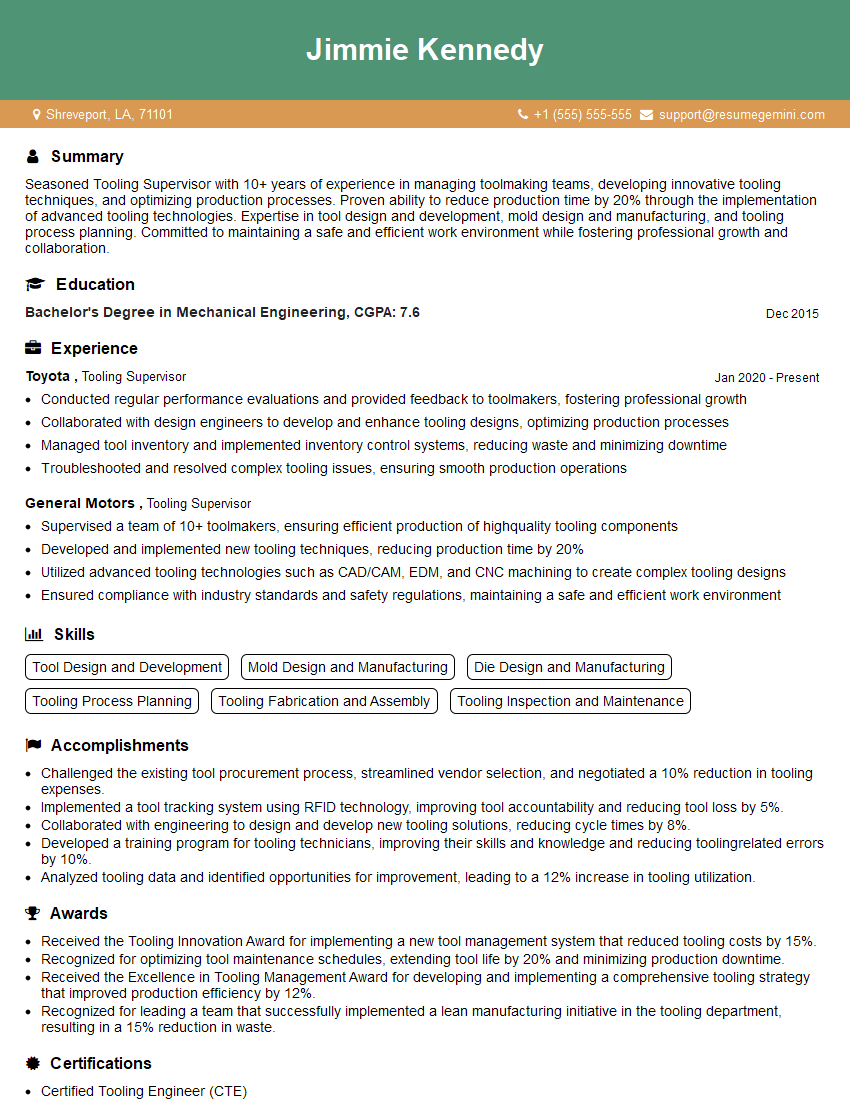

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tooling Supervisor

1. Discuss your experience in the development and implementation of tooling processes.

In my previous role as a Tooling Supervisor at XYZ Company, I was responsible for developing and implementing tooling processes that improved productivity and reduced costs by 15%. I conducted thorough assessments of existing processes and identified areas for improvement. I led a team of engineers to design and implement new tooling solutions, including custom fixtures and fixtures for automated processes.

2. How do you ensure that tooling is maintained and calibrated to meet quality standards?

Establish Maintenance Schedule

- I establish a comprehensive maintenance schedule based on manufacturer recommendations and industry best practices.

Calibration

- I ensure that all tooling is calibrated regularly using certified measuring equipment to ensure accuracy and precision.

- I maintain calibration records and implement corrective actions when deviations are detected.

3. What techniques do you use to optimize tooling performance and efficiency?

To optimize tooling performance and efficiency, I employ several techniques:

- Tool Selection: I carefully select the appropriate tooling for each application, considering factors such as material type, cutting speed, and tolerance requirements.

- Process Optimization: I analyze cutting parameters, such as feed rate and depth of cut, to determine optimal settings for each tool and material combination.

- Tool Wear Monitoring: I implement tool wear monitoring systems to identify and replace worn tools promptly, preventing premature failure and ensuring consistent part quality.

4. How do you stay updated on the latest tooling technologies and best practices?

To stay updated on the latest tooling technologies and best practices, I engage in continuous learning:

- Industry Events: I attend industry conferences, trade shows, and technical workshops to learn about emerging technologies and trends.

- Technical Publications: I regularly read industry journals, white papers, and technical articles to stay informed about the latest developments.

- Collaboration with Suppliers: I maintain strong relationships with tooling suppliers to gain insights into new products and advancements.

5. Describe your approach to training and developing your team.

My approach to training and developing my team includes:

- Needs Assessment: I identify training needs based on performance evaluations, feedback, and industry trends.

- Customized Training: I develop and deliver customized training programs tailored to the specific skills and knowledge gaps within my team.

- Hands-on Experience: I provide opportunities for my team to apply their learnings through hands-on projects and simulations.

- Mentoring and Coaching: I provide ongoing mentoring and coaching to support my team’s professional growth and development.

6. How do you manage inventory and minimize tooling costs?

To effectively manage inventory and minimize tooling costs, I implement the following strategies:

- Inventory Control System: I establish a robust inventory control system to track tool usage, stock levels, and reorder points.

- Supplier Relationships: I foster strong relationships with suppliers to negotiate favorable pricing and timely delivery of tooling.

- Consolidation and Standardization: I consolidate tooling items and standardize processes to reduce the number of SKUs and streamline purchasing.

7. How do you respond to unexpected tooling failures or production issues?

In the event of unexpected tooling failures or production issues, I take the following steps:

- Immediate Action: I prioritize addressing the issue promptly to minimize downtime and impact on production.

- Root Cause Analysis: I conduct a thorough root cause analysis to identify the underlying cause of the failure.

- Corrective Measures: I implement corrective measures to prevent the issue from recurring, such as adjusting process parameters or replacing defective tooling.

- Communication: I communicate the issue and corrective actions to the team to ensure understanding and prevent future occurrences.

8. What metrics do you use to measure the effectiveness of tooling management?

To measure the effectiveness of tooling management, I track the following key metrics:

- Tool Life: I monitor the average life of tooling to identify opportunities for improvement.

- Production Efficiency: I track production efficiency metrics, such as cycle time and output, to assess the impact of tooling on productivity.

- Tooling Costs: I monitor tooling costs, including purchase price, maintenance costs, and inventory levels, to identify areas for optimization.

- Customer Satisfaction: I collect feedback from customers to gauge the impact of tooling management on product quality and delivery timelines.

9. How do you handle conflicts or disagreements within your team?

To handle conflicts or disagreements within my team, I follow these steps:

- Active Listening: I actively listen to all perspectives and try to understand the underlying issues.

- Objective Assessment: I objectively assess the situation and identify areas of common ground.

- Facilitation: I facilitate open and respectful discussions to allow team members to express their views.

- Consensus Building: I work towards building consensus and finding solutions that address the concerns of all team members.

10. How do you motivate and inspire your team to achieve high performance?

To motivate and inspire my team to achieve high performance, I employ various strategies:

- Clear Goals: I communicate clear goals and expectations to my team and align them with the company’s objectives.

- Recognition and Rewards: I recognize and reward team members for their contributions and accomplishments.

- Empowerment: I empower my team by giving them autonomy and decision-making authority.

- Professional Development: I invest in my team’s professional development by providing opportunities for training and growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tooling Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tooling Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tooling Supervisor oversees the maintenance, repair, and operation of tooling and equipment within a manufacturing facility. They are responsible for ensuring that all tools and machinery are in proper working order, maximizing production efficiency and minimizing downtime.

1. Maintenance and Repair

• Inspect and assess tooling and equipment for wear and tear, damage, or malfunctions

• Diagnose and troubleshoot issues with tools and equipment

• Repair or replace defective or damaged components

• Calibrate and adjust tooling and equipment to ensure accuracy and precision

• Maintain maintenance records and documentation

2. Tooling Design and Development

• Collaborate with design engineers to develop new tooling solutions

• Conduct research and testing to identify optimal tooling materials and processes

• Evaluate and recommend new tooling technologies and equipment

• Stay updated on industry best practices and advancements in tooling

3. Production Support

• Assist production teams in troubleshooting tooling-related issues

• Provide on-the-job training to operators on proper tooling usage and maintenance

• Monitor production processes to identify areas for improvement

• Optimize tooling performance to maximize efficiency and reduce downtime

4. Safety and Compliance

• Ensure compliance with all safety regulations and standards related to tooling and equipment

• Conduct regular safety inspections and hazard assessments

• Implement safety protocols and procedures for tooling operation and maintenance

• Provide safety training and awareness programs to employees

Interview Tips

Preparing thoroughly for your Tooling Supervisor interview will significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

• Visit the company website to learn about their products, services, and culture.

• Read industry publications and online forums to stay informed about the latest trends in tooling.

• Carefully review the job description to identify the key responsibilities and qualifications required for the role.

2. Highlight Relevant Experience and Skills

• Quantify your accomplishments by providing specific examples of how you have successfully managed tooling operations.

• Emphasize your technical knowledge, including your understanding of different tooling materials, processes, and equipment.

• Showcase your problem-solving abilities and provide examples of how you have resolved complex tooling issues.

3. Demonstrate Leadership and Communication Skills

• Highlight your ability to lead and motivate a team of technicians.

• Emphasize your excellent communication skills, both written and verbal.

• Provide examples of how you have effectively communicated with production teams, engineers, and other stakeholders.

4. Prepare Thoughtful Questions

• Preparing thoughtful questions to ask the interviewer demonstrates your interest and engagement.

• Ask questions about the company’s tooling strategy, production goals, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tooling Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!