Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Toolmaker A position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

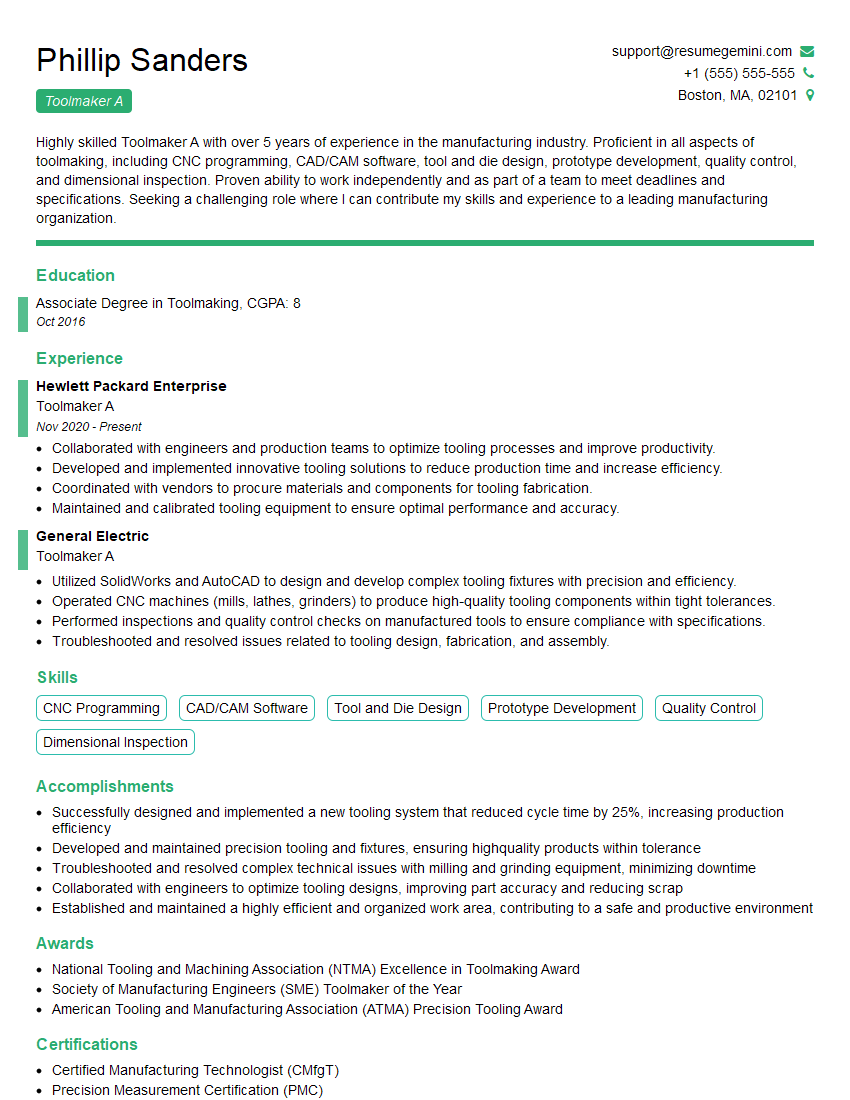

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolmaker A

1. Explain the process of designing and creating a mold.

- Start with a product design and determine the appropriate mold type.

- Create a 3D model of the mold using CAD software.

- Select the mold materials and determine the machining processes for each component.

- Fabricate the mold components using CNC machines or other precision machining equipment.

- Assemble the mold and conduct testing to ensure proper operation.

2. How do you ensure the accuracy and precision of your work?

Quality Control Measures

- Use precision measuring tools such as calipers, micrometers, and CMMs.

- Follow established quality control procedures and standards.

- Inspect molds at various stages of the production process.

Attention to Detail

- Pay close attention to dimensions, tolerances, and surface finishes.

- Double-check measurements and calculations.

- Take pride in producing high-quality molds.

3. What are the different types of mold materials and when would you use each one?

- Aluminum: Lightweight, machinable, suitable for low-volume production.

- Steel: Durable, wear-resistant, ideal for high-volume production of complex parts.

- Copper: High thermal conductivity, used for molds that require rapid heat transfer.

- Beryllium Copper: Excellent electrical conductivity, used in molds for electronic components.

- Nickel-plated molds: Corrosion-resistant, used for molds that produce plastic parts with high surface finish requirements.

4. Describe your experience in using CNC machines for mold making.

- Familiar with different types of CNC machines (e.g., vertical machining centers, milling machines).

- Proficient in using CAD/CAM software for programming CNC operations.

- Expertise in setting up, operating, and maintaining CNC machines.

- Experience in machining complex mold components with high precision.

- Knowledge of tool selection, feed rates, and cutting parameters.

5. How do you handle complex mold designs and tight tolerances?

- Collaboration: Work closely with design engineers to understand the design intent and identify potential challenges.

- Planning: Develop a detailed manufacturing plan to ensure accuracy and efficiency.

- Precision Machining: Use CNC machines and precision tooling to achieve tight tolerances.

- Inspection: Conduct regular inspections throughout the production process to identify and correct errors early on.

- Adaptive Strategies: Adjust machining parameters and techniques as needed to overcome challenges.

6. Describe your experience in mold testing and troubleshooting.

- Testing: Conduct various tests such as flow analysis, part measurement, and visual inspection to assess mold performance.

- Troubleshooting: Analyze test results, identify potential issues, and develop solutions to optimize mold operation.

- Problem-Solving: Apply technical knowledge and experience to resolve mold defects and improve production efficiency.

7. What are the challenges you have faced in mold making and how did you overcome them?

- Complex Geometry: Overcoming challenges in machining intricate mold features by using specialized tooling and advanced machining techniques.

- Tight Tolerances: Achieving precise dimensions by implementing rigorous quality control measures and using precision measuring equipment.

- Material Compatibility: Selecting the appropriate mold materials to suit the desired part properties and production requirements.

8. Are you familiar with the latest advancements in mold making technology?

- Additive Manufacturing: Knowledge of 3D printing techniques for mold making, such as SLS and FDM.

- CAD/CAM Software: Expertise in using advanced software for mold design, optimization, and simulation.

- Inspection Technology: Familiarity with non-destructive testing (NDT) methods for mold quality assurance.

9. Provide an example of a time when you went above and beyond in your role as a toolmaker.

- Solving a Critical Production Issue: Identifying and resolving a manufacturing problem that was impacting production efficiency.

- Developing Innovative Solutions: Designing and implementing custom tooling or mold modifications to improve mold performance.

- Mentoring and Training: Providing guidance and support to new or junior toolmakers.

10. Do you have any questions for me about the role or the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolmaker A.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolmaker A‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolmaker A, as a key part of the production line, is responsible for creating, maintaining, and repairing tools, dies, jigs, and fixtures utilized in the production process.

1. Tool and Die Making

The role primarily involves creating and maintaining tools and dies, including punches, forming dies, and other components of stamping and forming equipment.

- Design and fabricate new tools and dies according to specifications.

- Modify and repair existing tools and dies to ensure optimal performance.

2. Fixture and Jig Building

Toolmaker A is also responsible for the creation and maintenance of jigs and fixtures, which are used to hold and guide workpieces during production.

- Design and build jigs and fixtures to meet specific production requirements.

- Maintain and repair jigs and fixtures to ensure accuracy and efficiency.

3. Equipment Maintenance and Repair

Toolmaker A plays a crucial role in the maintenance and repair of production equipment.

- Perform routine maintenance and repairs on production equipment.

- Troubleshoot and resolve equipment issues to minimize downtime.

4. Quality Control

Toolmaker A contributes to quality control by ensuring the accuracy and precision of tools and equipment.

- Inspect tools and equipment to ensure they meet specifications.

- Identify and correct any deviations from specifications.

Interview Tips

Preparing for an interview for the Toolmaker A position requires thorough research, practice, and a positive attitude. Here are some valuable tips to help candidates ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and industry standing. Understand the specific responsibilities of the Toolmaker A role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages.

- Read articles and industry reports related to the company and its products.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in tool and die making, fixture and jig building, and equipment maintenance. Quantify your accomplishments and provide specific examples of your work.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Be prepared to discuss your knowledge of different types of tools, dies, and equipment.

3. Demonstrate Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve issues. Share examples of how you have identified and solved problems in previous roles.

- Describe a time when you successfully diagnosed and repaired a complex piece of equipment.

- Explain how you approach problem-solving and decision-making.

4. Show Enthusiasm and Passion

Convey your interest in the Toolmaker A role and the manufacturing industry. Highlight your passion for precision and attention to detail.

- Express your desire to contribute your skills to the company’s success.

- Ask thoughtful questions about the company’s production processes and future plans.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Toolmaker A interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!