Are you gearing up for a career in Toolmaker Grade Three? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Toolmaker Grade Three and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

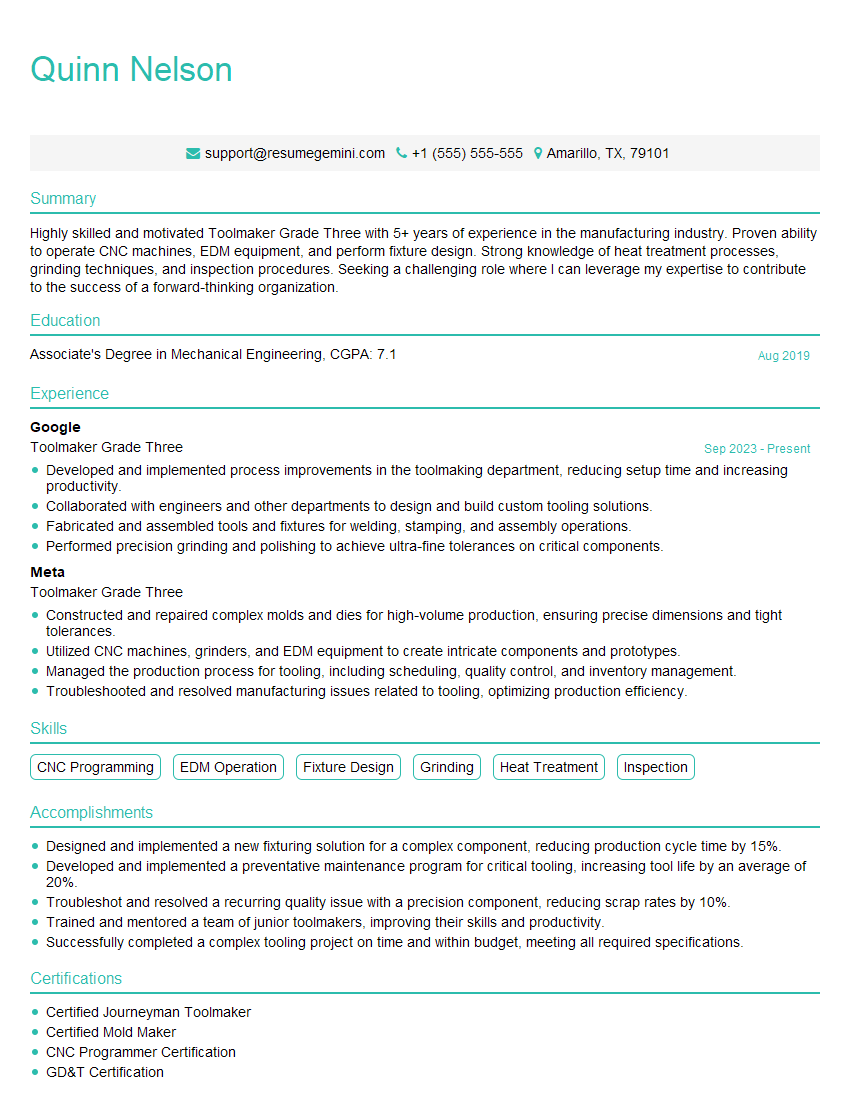

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolmaker Grade Three

1. What are the different types of cutting tools used in toolmaking?

There are various types of cutting tools employed in toolmaking, including:

- Milling cutters for shaping and contouring surfaces

- Turning tools for creating cylindrical and conical shapes

- Drilling tools for creating holes

- Boring tools for enlarging existing holes

- Reaming tools for finishing holes to precise dimensions

- Tapping tools for creating threads

- Broaching tools for creating internal or external shapes

2. How do you select the appropriate cutting tool for a specific task?

Factors to Consider:

- Material being cut

- Desired surface finish

- Accuracy and precision requirements

- Tool speed and feed rate

- Tool life and durability

Selection Process:

- Identify the workpiece material and its properties

- Determine the desired surface finish and tolerance

- Calculate appropriate cutting speeds and feed rates

- Select a tool with the correct geometry and material for the operation

3. What are the principles of heat treatment in toolmaking?

Heat treatment is a critical process in toolmaking, involving controlled heating and cooling to alter the properties of metal alloys. Key principles include:

- Annealing: Softens metal by heating and slowly cooling

- Hardening: Increases hardness by heating to a critical temperature and rapidly cooling (quenching)

- Tempering: Relieves brittleness caused by hardening, while maintaining hardness

- Case hardening: Creates a hard outer surface while leaving the core softer

- Cryogenic treatment: Further enhances hardness and reduces brittleness

4. How do you maintain and inspect cutting tools and machine tools?

- Regular cleaning and lubrication

- Checking for wear and damage

- Resharpening or replacing cutting tools as needed

- Calibrating and adjusting machine tools

- Visual inspection for cracks or defects

- Dimensional inspection using measuring tools

- Checking machine accuracy and precision

- Identifying and addressing any performance issues

Maintenance:

Inspection:

5. What techniques do you use for precision machining and assembly?

- CNC programming and operation: Writing and executing programs for computer-controlled machines

- Precision measuring tools: Using micrometers, calipers, and height gauges for accurate measurements

- Datum establishment: Setting a reference point from which measurements are taken

- Fixture design and use: Creating and utilizing fixtures to ensure precise workpiece positioning

- Shimming and alignment: Adjusting components with shims to achieve desired tolerances

6. How do you troubleshoot and resolve problems with tooling and machinery?

Troubleshooting involves a systematic approach to identify and fix issues:

- Problem identification: Observation, inspection, and analysis to determine the problem

- Root cause analysis: Investigating underlying factors contributing to the problem

- Solution determination: Exploring various solutions and selecting the most appropriate

- Implementation: Applying the solution and verifying its effectiveness

- Preventive measures: Identifying and implementing steps to prevent similar problems in the future

7. How do you stay up-to-date with new technologies and best practices in toolmaking?

To remain current, I actively engage in the following:

- Industry seminars and conferences: Attending events to learn about new advancements

- Trade publications and technical journals: Reading industry magazines and journals

- Online resources: Exploring technical websites, forums, and online courses

- Collaboration with colleagues: Discussing new technologies and sharing knowledge

- Professional development: Pursuing industry certifications and ongoing training

8. What are your strengths and weaknesses as a toolmaker?

Strengths:

- Expertise in precision machining and assembly techniques

- Strong analytical and problem-solving abilities

- Excellent attention to detail and quality craftsmanship

- Proficient in CNC programming and operation

- Ability to work independently and as part of a team

Weaknesses:

- Limited experience with specific types of toolmaking equipment

- Could improve efficiency in certain aspects of toolmaking processes

9. How do you handle working under pressure and meeting deadlines?

I thrive under pressure and am highly motivated to meet deadlines. My approach includes:

- Effective time management: Prioritizing tasks and allocating time wisely

- Clear communication: Establishing expectations and keeping stakeholders informed

- Efficient problem-solving: Anticipating potential challenges and developing contingency plans

- Adaptability: Adjusting to changing priorities and unexpected situations

- Focus under pressure: Maintaining concentration and delivering quality work even in demanding environments

10. Why are you interested in this toolmaker position?

I am eager to join your organization as a Toolmaker Grade Three due to several reasons:

- Alignment with my skills: My technical expertise and experience align perfectly with the requirements of this role.

- Growth opportunities: I am confident in my ability to contribute to your team and grow professionally within your organization.

- Industry reputation: Your company is renowned for its commitment to quality and innovation, which aligns with my own values.

- Team environment: I am a highly motivated and collaborative team player, and I believe I can make a valuable contribution to your team dynamics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolmaker Grade Three.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolmaker Grade Three‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolmaker Grade Three is a skilled position that requires a deep understanding of toolmaking principles and techniques. The primary responsibility of this role is to design, develop, and maintain tooling, fixtures, and equipment used in manufacturing processes.

1. Tool Design and Development

Collaborate with engineers and designers to create and execute tool designs.

- Analyze product specifications and drawings to determine tool requirements.

- Develop and optimize tool designs using computer-aided design (CAD) software.

2. Tool Fabrication and Assembly

Fabricate and assemble tools according to design specifications.

- Operate a variety of machines, including lathes, mills, and grinders, to create tool components.

- Weld, fit, and assemble tools to ensure accuracy and precision.

3. Tool Inspection and Maintenance

Inspect and maintain tools to ensure their accuracy and functionality.

- Conduct quality control checks to verify tool dimensions and performance.

- Troubleshoot and repair tools to minimize downtime and maintain productivity.

4. Process Improvement and Training

Contribute to continuous process improvement and train junior toolmakers.

- Identify areas for improvement in tool design and manufacturing processes.

- Provide guidance and training to less experienced toolmakers to develop their skills.

Interview Tips

Preparing for a Toolmaker Grade Three interview requires a thorough understanding of the role and its responsibilities. Here are some tips to help you succeed:

1. Research the Company and the Position

Before the interview, take time to research the company and the specific Toolmaker Grade Three position. Learn about the company’s products, services, and industry. Review the job description carefully to understand the key requirements and responsibilities.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions. Practice speaking about your skills and experience in a clear and concise manner. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Your Technical Skills

Emphasize your proficiency in tool design, fabrication, and maintenance. Provide specific examples of projects where you applied these skills. Quantify your accomplishments whenever possible, using metrics such as reduced production costs or increased tool life.

4. Showcase Your Problem-Solving Abilities

Toolmakers often face challenges during the design and manufacturing process. Highlight your ability to analyze problems, develop creative solutions, and troubleshoot effectively.

5. Be Prepared for Technical Questions

The interviewer may ask technical questions to assess your knowledge. Be prepared to discuss topics such as tool materials, machining processes, and quality control techniques.

Next Step:

Now that you’re armed with the knowledge of Toolmaker Grade Three interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Toolmaker Grade Three positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini