Are you gearing up for a career in Toolmaker Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Toolmaker Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

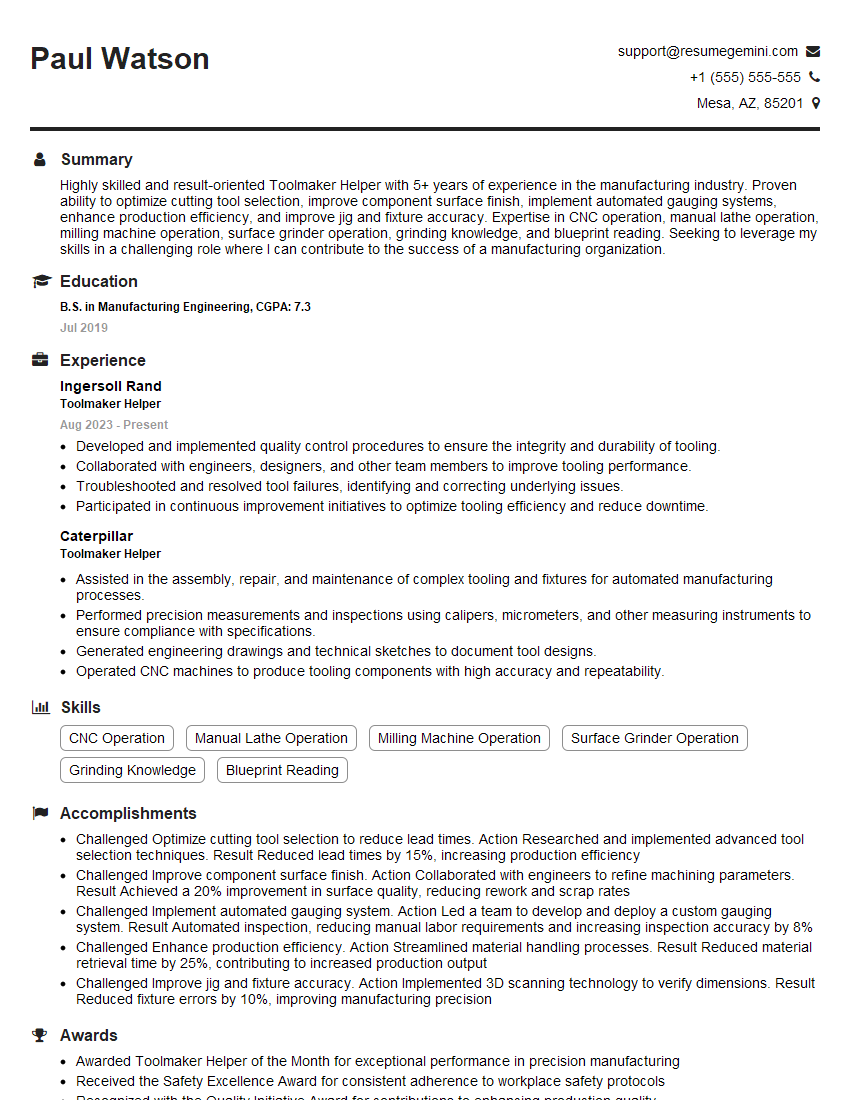

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolmaker Helper

1. What are the different types of toolmaking?

- Plastic Mold Toolmaking: Production of molds for parts made of a plastic material

- Die Casting Toolmaking: Production of dies for components that are made as one-piece castings

- Metal Stamping Toolmaking: Production of stamping dies used for making sheet metal parts

2. What are the different types of materials used in toolmaking?

- Steel: Hard and durable material used for cutting tools, molds, and dies

- Carbide: Very hard material used for cutting tools and wear-resistant parts

- Aluminum: Lightweight and corrosion-resistant material used for mold and die components

- Plastic: Used for prototype molds, rapid tooling, and low-volume production

3. What are the different types of machines used in toolmaking?

- CNC Machines: Used for precise cutting, milling, and drilling

- Grinding Machines: Used for finishing and precision shaping

- EDM Machines: Used for intricate cutting and shaping using electrical discharge

4. What are the different methods used for heat treatment of tools?

- Annealing: Heating and slowly cooling to soften the material and reduce brittleness

- Hardening: Heating and rapidly cooling to increase hardness and wear resistance

- Tempering: Heating to a specific temperature and holding to achieve desired hardness and toughness

5. What are the different types of fits used in toolmaking?

- Clearance Fit: Loose fit with a gap between mating parts

- Transition Fit: Fit with slight interference or clearance, depending on tolerance

- Interference Fit: Tight fit where mating parts are pressed together

6. What are the different types of tolerances used in toolmaking?

- Geometric Tolerances: Control shape, size, and orientation

- Dimensional Tolerances: Control specific dimensions

- Surface Tolerances: Control surface finish and texture

7. What are the different types of measuring tools used in toolmaking?

- Calipers: Used to measure lengths, diameters, and depths

- Micrometers: Used for precise measurements of small dimensions

- Dial Indicators: Used to measure small movements and deviations

8. What are the different types of hand tools used in toolmaking?

- Files: Used for shaping and smoothing surfaces

- Scrapers: Used for removing material and finishing surfaces

- Hammers: Used for driving, shaping, and assembling

9. What are the different types of safety precautions to be taken in toolmaking?

- Wear appropriate protective gear (e.g., safety glasses, gloves)

- Operate machines safely and follow established procedures

- Handle tools and materials with care

10. What are some of the challenges faced by a Toolmaker Helper?

- Working with precise measurements and tolerances

- Handling hazardous materials and sharp tools

- Meeting tight deadlines and ensuring quality

11. What are the different career paths available for a Toolmaker Helper?

- Toolmaker

- Machinist

- Quality Control Inspector

12. What are the qualities of a successful Toolmaker Helper?

- Attention to detail and precision

- Strong mechanical aptitude

- Ability to work independently and as part of a team

13. What are some of the software programs used in toolmaking?

- CAD/CAM software for designing and machining

- Metrology software for measurement and inspection

- PDM/PLM software for managing tool data and documentation

14. What are the different industry standards and regulations applicable to toolmaking?

- ISO 9001: Quality Management System

- ASME Y14.5M: Dimensioning and Tolerancing

- ANSI B4.1: Surface Texture

15. What is your experience with using different types of measuring tools and instruments?

- Extensive experience using calipers, micrometers, and dial indicators for precise measurements

- Proficient in using coordinate measuring machines (CMMs) for complex part inspection

- Familiar with various non-destructive testing (NDT) methods, such as ultrasonic and magnetic particle inspection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolmaker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolmaker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolmaker Helpers assist Toolmakers in the fabrication, assembly, and repair of jigs, fixtures, dies, molds, and gauges used in manufacturing processes. They perform various tasks under the supervision of experienced Toolmakers.

1. Assist in Tool Fabrication

Toolmaker Helpers help Toolmakers create new tools and modify existing ones. They assist with tasks such as:

- Setting up and operating machines like lathes, mills, and grinders

- Measuring and inspecting parts to ensure accuracy and quality

- Assembling and disassembling tools and components

- Performing heat treatment and other processes to enhance tool durability

2. Aid in Tool Maintenance

Toolmaker Helpers assist in maintaining and repairing tools to ensure optimal performance. They may:

- Inspect tools for wear and tear

- Sharpen cutting tools

- Lubricate and adjust tools

- Troubleshoot and resolve tool malfunctions

3. Support Tool Design

Toolmaker Helpers may assist Toolmakers in designing and developing new tools. They can:

- Review blueprints and design specifications

- Provide input on material selection and manufacturing processes

- Help create prototypes and test tools

4. Maintain a Clean and Organized Work Area

Toolmaker Helpers are responsible for maintaining a clean and organized work area. They may:

- Clean and lubricate machinery

- Organize tools and materials

- Dispose of waste properly

Interview Tips

Preparing thoroughly can significantly improve your chances of acing your Toolmaker Helper interview. Here are some valuable tips and hacks:

1. Research the Company and the Role

Before the interview, take time to research the company and the specific Toolmaker Helper role. This will help you understand the company’s culture, values, and the requirements of the position. You can visit the company’s website, read industry news, and check Glassdoor for insights.

- Practice answering common interview questions related to your skills, experience, and why you’re interested in the role.

- Prepare questions to ask the interviewer, demonstrating your interest and engagement.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible, using specific numbers and metrics. For example, instead of saying “I assisted in tool fabrication,” you could say.

- “Assembled over 500 tools within a tight deadline, ensuring accuracy and meeting quality standards.”

- “Reduced tool maintenance downtime by 20% through proactive inspection and preventive maintenance.”

3. Showcase Your Teamwork and Communication Skills

Toolmaker Helpers often work in teams and collaborate with Toolmakers and other professionals. Highlight your ability to work effectively in a team environment and communicate clearly. Provide examples of projects where you successfully collaborated with others.

- Describe a situation where you worked with a team to solve a complex tooling issue.

- Explain how you effectively communicated with Toolmakers to ensure smooth workflow and avoid misunderstandings.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to toolmaking processes, machine operation, and tool maintenance. Review basic concepts of machining, grinding, heat treatment, and tool design. If you have specific experience with any particular software or equipment, mention that during the interview.

- Study the basics of toolmaking materials, such as metals, plastics, and composites.

- Familiarize yourself with common industry standards and quality control procedures.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive punctually, as it demonstrates respect for the interviewer’s time. Being prepared, confident, and enthusiastic will increase your chances of making a positive impression and securing the Toolmaker Helper position.

- Wear business attire or neat, clean clothing that is appropriate for a manufacturing environment.

- Be mindful of your body language and maintain eye contact during the interview.

Next Step:

Now that you’re armed with the knowledge of Toolmaker Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Toolmaker Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini