Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Toolmaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

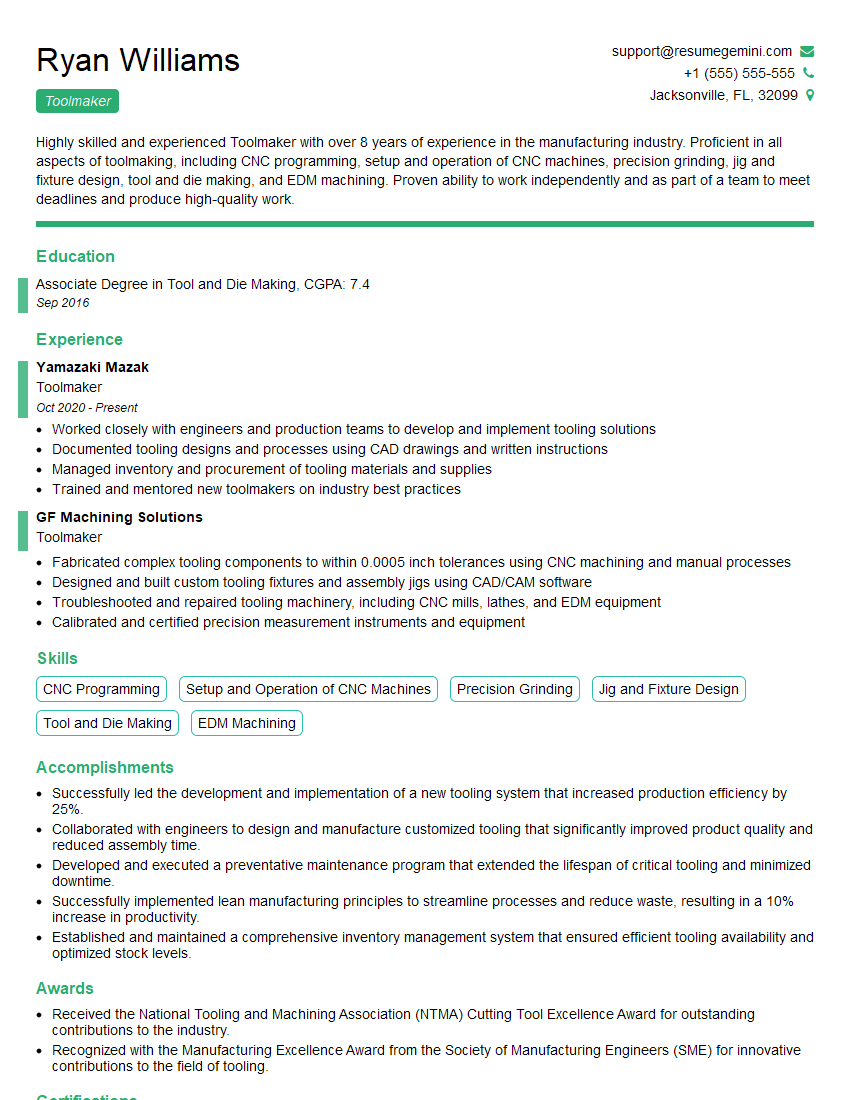

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolmaker

1. Describe the key steps involved in designing and manufacturing a mold for injection molding.

- Understanding the product design and its requirements.

- Developing a mold design based on product specifications.

- Selecting appropriate materials for the mold.

- Producing the mold components using precision machining and other manufacturing techniques.

- Assembling and testing the mold to ensure it meets quality standards.

- Optimizing the mold design for efficient production and product quality.

2. Explain the different types of mold materials used in plastic injection molding.

Mold Steel

- High durability and wear resistance for long-lasting molds.

- Precision machining capabilities for intricate designs.

Beryllium Copper

- Excellent thermal conductivity for rapid cooling of plastic.

- High strength and resistance to wear.

Aluminum

- Lightweight and inexpensive material.

- Suitable for low-volume production or prototype molds.

3. What are the common challenges faced in mold design and manufacturing?

- Ensuring dimensional accuracy and precision.

- Balancing cost and performance requirements.

- Designing for ease of mold maintenance and repair.

- Avoiding defects such as sink marks, flash, and warpage in the molded products.

- Optimizing mold design for efficient production cycles.

4. Describe your experience in using computer-aided design (CAD) software for mold design.

- Proficient in using CAD software such as SolidWorks, AutoCAD, or CATIA.

- Creating 3D models of mold designs with precise dimensions.

- Generating technical drawings and documentation for mold manufacturing.

- Using CAD to optimize mold design for functionality and manufacturability.

5. What are your strengths and weaknesses as a Toolmaker?

- Strengths:

- Strong technical skills in mold design and manufacturing.

- Proficient in using CAD software and manufacturing equipment.

- Attention to detail and commitment to quality.

- Weaknesses:

- Limited experience in a high-volume production environment.

- Still developing supervisory and management skills.

6. Explain the importance of quality control in mold making.

- Ensuring the accuracy and precision of molds.

- Preventing defects and maintaining product quality.

- Reducing production downtime and maintenance costs.

- Meeting customer specifications and industry standards.

- Building a reputation for reliability and quality.

7. How do you stay updated with the latest advancements in mold making technology?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussions.

- Collaborating with other professionals in the field.

- Exploring new technologies and materials.

8. Describe a project where you successfully solved a complex problem in mold design or manufacturing.

- Project Description: Designed and manufactured a complex mold for a high-precision component.

- Problem: Ensuring uniform cooling and preventing warpage in the molded part.

- Solution: Implemented a conformal cooling system with optimized channel placement and flow rates.

- Result: Successfully produced parts that met tight dimensional tolerances and quality standards.

9. What are your career goals as a Toolmaker?

- Advance my technical skills and become a highly skilled mold designer.

- Contribute to the development of innovative mold making techniques.

- Lead a team of mold makers and manage complex projects.

- Establish a reputation as a trusted and reliable professional in the industry.

10. Do you have any questions for me about the position or the company?

Here you can ask any questions that you have prepared before for the interviewer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolmakers play a vital role in manufacturing industries, specializing in creating and maintaining tools and fixtures used to produce various components and products. Their responsibilities encompass a wide range of tasks, requiring a combination of technical expertise, problem-solving abilities, and precision craftsmanship.

1. Tool Design and Development

Toolmakers participate in the design and development of new or improved tools and fixtures. They analyze product specifications, consult with engineers, and utilize CAD software to create detailed drawings.

- Design tooling concepts and prototypes

- Conduct feasibility studies and analyze manufacturing processes

2. Tool Fabrication and Assembly

Toolmakers are responsible for fabricating, assembling, and installing tools and fixtures using various metalworking techniques, including machining, welding, and grinding.

- Operate CNC machines, lathes, and other precision equipment

- Assemble and fit complex tooling components

3. Tool Inspection and Maintenance

Toolmakers regularly inspect and maintain tools and fixtures to ensure optimal performance and accuracy. They perform precision measurements, test operations, and make necessary adjustments or repairs.

- Conduct periodic inspections and calibrations

- Diagnose and troubleshoot tooling issues

4. Quality Control and Assurance

Toolmakers are responsible for maintaining high standards of quality in their work. They ensure that tools and fixtures meet specified tolerances and production requirements.

- Perform dimensional inspections and quality checks

- Document and track tooling performance

Interview Tips

Preparing thoroughly for a Toolmaker interview is essential to showcase your skills, experience, and suitability for the role. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company, its products, and the specific toolmaker position you are applying for. This knowledge will enable you to tailor your responses and demonstrate your interest in the role.

- Visit the company website and review their products and services.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Highlight Your Technical Expertise

Toolmakers are highly skilled individuals with a deep understanding of metalworking techniques and manufacturing processes. Be sure to emphasize your knowledge of:

- CNC machining, including programming and operation

- Welding and fabrication techniques

- Quality control and inspection procedures

- CAD software and design principles

3. Showcase Your Problem-Solving Abilities

Toolmakers often face challenges and unexpected situations on the job. Highlight your ability to think critically, troubleshoot problems, and develop creative solutions.

- Share examples of times you identified and resolved tooling issues.

- Describe how you approached complex design problems.

4. Emphasize Your Precision and Attention to Detail

Toolmakers are responsible for creating and maintaining highly precise tools. Emphasize your attention to detail and commitment to quality.

- Explain your understanding of tolerances and measurement techniques.

- Describe your experience in using precision instruments and gauges.

5. Practice Your Communication Skills

Toolmakers often work in teams and must be able to communicate effectively with engineers, machinists, and other colleagues. Practice your speaking and listening skills.

- Prepare responses to common interview questions.

- Practice explaining technical concepts in a clear and concise manner.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Toolmaker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.