Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Toolroom Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

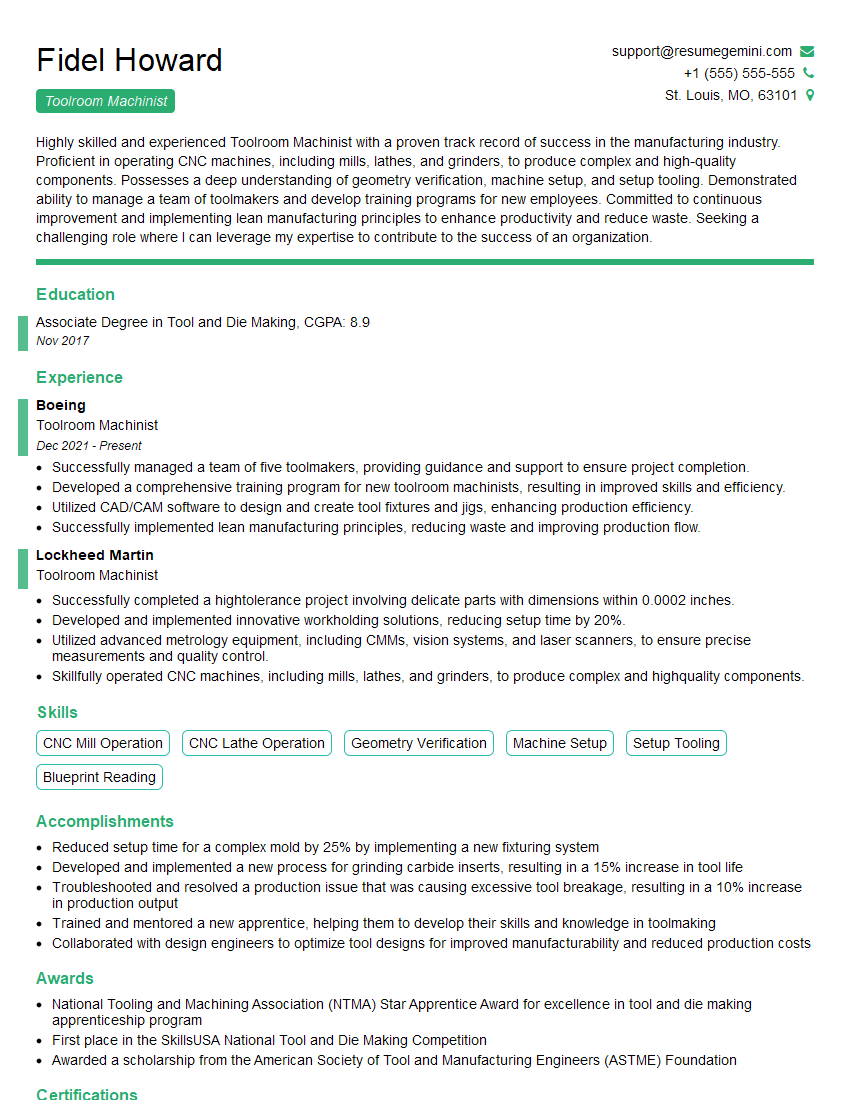

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolroom Machinist

1. Explain the different types of cutting tools used in toolroom machining and their applications?

- Single point cutting tools: These tools have a single cutting edge and are used for operations like turning, facing, and boring.

- Multi-point cutting tools: These tools have multiple cutting edges and are used for operations like milling, drilling, and tapping.

- Abrasive cutting tools: These tools use abrasive materials to cut through materials and are used for operations like grinding and cutting.

2. Describe the process of setting up and operating a CNC lathe?

Tool Setup

- Mount the workpiece on the chuck or faceplate

- Install the cutting tools in the tool turret

- Set the tool offsets and cutting parameters

Operating the Lathe

- Load the CNC program into the control panel

- Start the spindle and coolant

- Monitor the cutting process and make adjustments as needed

3. Explain the difference between conventional and climb milling?

- Conventional milling: The cutting tool moves against the direction of rotation. This results in a smoother finish but generates more heat and can cause chatter.

- Climb milling: The cutting tool moves in the same direction as the rotation. This allows for faster cutting speeds and reduces chatter but can result in a rougher finish.

4. Describe the use of precision measuring instruments in toolroom machining?

- Calipers: Used to measure linear dimensions

- Micrometers: Used to measure small linear dimensions with high precision

- Dial indicators: Used to measure deviations from a reference surface

- Coordinate measuring machines (CMMs): Used to measure complex shapes and dimensions in three dimensions

5. Explain the importance of toolpath optimization in CNC machining?

- Reduces machining time by optimizing the path of the cutting tool

- Improves surface finish by reducing chatter and vibration

- Extends tool life by minimizing cutting forces

- Reduces energy consumption by optimizing the cutting process

6. Describe the different types of jigs and fixtures used in toolroom machining?

- Drill jigs: Used to guide drills

- Milling fixtures: Used to hold workpieces during milling operations

- Lathe fixtures: Used to hold workpieces during turning operations

- Grinding fixtures: Used to hold workpieces during grinding operations

7. Explain the process of heat treatment in toolroom machining?

- Annealing: Heating and slowly cooling a metal to make it softer and more ductile

- Hardening: Heating and rapidly cooling a metal to make it harder and more wear-resistant

- Tempering: Reheating a hardened metal to reduce its hardness and make it more tough

8. Describe the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) in toolroom machining?

- CAD: Used to create 3D models of parts and assemblies

- CAM: Used to generate CNC programs from CAD models

- Benefits: Improved accuracy, reduced lead time, and increased productivity

9. Explain the importance of safety in toolroom machining?

- Wearing appropriate safety gear

- Following proper operating procedures

- Inspecting equipment regularly

- Maintaining a clean and organized work area

10. Describe the different career paths available to toolroom machinists?

- CNC programmer

- Quality control inspector

- Production supervisor

- Tool and die maker

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolroom Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolroom Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolroom Machinists are skilled professionals responsible for creating and maintaining precision tools, jigs, and fixtures used in manufacturing processes. Their primary duties include:

1. Tool and Fixture Fabrication

Creating new tools and fixtures from scratch using materials such as steel, aluminum, and plastics.

- Reading blueprints and specifications to determine tool requirements.

- Using CNC machines, lathes, mills, and other equipment to shape and finish tools to precise tolerances.

2. Tool Maintenance and Repair

Performing preventive maintenance and repairs on existing tools and fixtures to ensure optimal performance.

- Inspecting tools for wear and damage.

- Regrinding cutting tools, replacing worn components, and adjusting settings.

3. Quality Control

Ensuring that all tools and fixtures meet required specifications.

- Inspecting finished tools and fixtures using precision measuring equipment.

- Identifying and correcting any deviations from specifications.

4. Shop Floor Support

Providing technical support to other departments, such as production and engineering.

- Troubleshooting tool-related issues.

- Training and mentoring other team members on proper tool usage.

Interview Tips

To ace an interview for a Toolroom Machinist position, candidates should prepare thoroughly and present themselves as knowledgeable, skilled, and reliable individuals.

1. Research the Company and Industry

Be familiar with the company’s history, products, and industry trends. This shows that you are genuinely interested in the opportunity and have taken the time to understand the context.

- Visit the company’s website.

- Read industry publications and news articles.

2. Practice Your Technical Skills

Refresh your knowledge of machining techniques and equipment. Practice answering questions about your experience with specific tools, such as CNC machines, lathes, and mills.

- Review your resume and highlight your relevant skills and experience.

- Prepare examples of projects you have worked on that demonstrate your technical abilities.

3. Emphasize Your Problem-Solving Abilities

Toolroom Machinists often need to solve complex problems related to tool design and repair. Provide examples of times when you have identified and resolved technical issues effectively.

- Describe a situation where you encountered a tool-related problem and the steps you took to fix it.

- Explain how you troubleshoot malfunctions and identify root causes.

4. Highlight Your Attention to Detail

Toolroom Machinists must be meticulous in their work to ensure precision and accuracy. Use specific examples to demonstrate your ability to pay attention to detail and produce high-quality work.

- Describe a project where you achieved precise tolerances and met strict specifications.

- Emphasize your use of measurement equipment and quality control techniques.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Toolroom Machinist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Toolroom Machinist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.