Are you gearing up for a career in Top Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Top Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

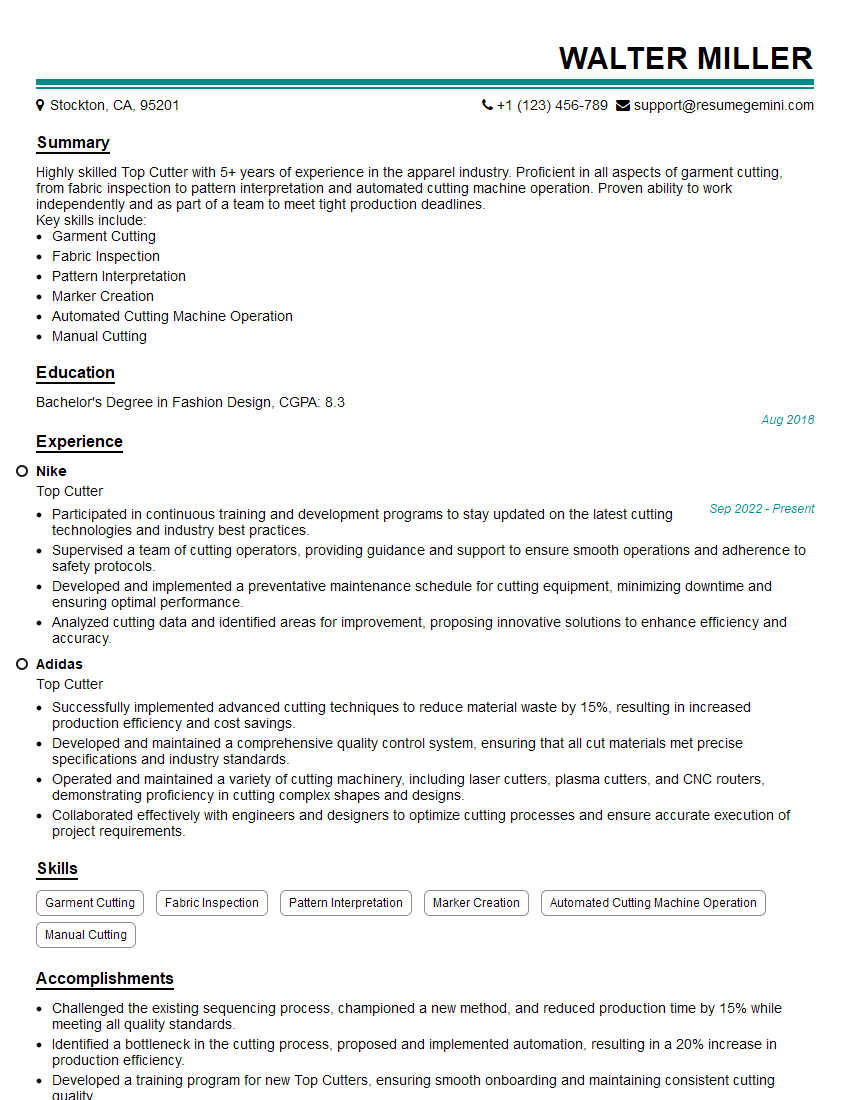

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Top Cutter

1. What are the key responsibilities of a Top Cutter in a steel plant?

- Operate and maintain a variety of cutting machines, such as plasma cutters, oxy-fuel cutting machines, and laser cutters.

- Read and interpret engineering drawings and specifications to determine cutting parameters.

- Set up and adjust cutting machines to achieve desired results.

- Inspect cut materials to ensure they meet specifications.

- Maintain a clean and organized work area.

2. What are the different types of cutting methods used in a steel plant?

Plasma Cutting

- Uses a high-temperature plasma arc to cut through metal.

- Can cut a wide variety of metals, including steel, stainless steel, and aluminum.

- Produces a clean, precise cut.

Oxy-Fuel Cutting

- Uses a mixture of oxygen and fuel gas to cut through metal.

- Can cut a wide variety of metals, including steel, stainless steel, and cast iron.

- Produces a rougher cut than plasma cutting.

Laser Cutting

- Uses a high-powered laser to cut through metal.

- Can cut a wide variety of metals, including steel, stainless steel, and aluminum.

- Produces a very clean and precise cut.

3. What are the safety precautions that must be taken when operating cutting machines?

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Never operate a cutting machine in a confined space.

- Keep the work area clean and free of debris.

- Be aware of the potential for electrical hazards.

- Never leave a cutting machine unattended.

4. What are the maintenance procedures that must be performed on cutting machines?

- Regularly clean and inspect the cutting machine.

- Lubricate the moving parts of the cutting machine.

- Check the cutting blades for wear and tear.

- Calibrate the cutting machine regularly.

- Perform any other maintenance tasks as recommended by the manufacturer.

5. What are the quality control procedures that must be followed when cutting materials?

- Inspect the raw material for defects.

- Set up the cutting machine according to the engineering drawings and specifications.

- Cut the material to the desired dimensions.

- Inspect the cut material for defects.

- Document the quality control procedures and results.

6. What are the troubleshooting procedures that must be followed when cutting machines malfunction?

- Identify the problem with the cutting machine.

- Consult the manufacturer’s manual for troubleshooting tips.

- Perform the necessary repairs or adjustments to the cutting machine.

- Test the cutting machine to ensure that it is functioning properly.

7. What are the different types of steel that are commonly cut in a steel plant?

- Carbon steel

- Stainless steel

- Aluminum

- Titanium

- Nickel alloys

8. What are the different thicknesses of steel that are commonly cut in a steel plant?

- Thin steel (less than 1/4 inch thick)

- Medium steel (1/4 inch to 1 inch thick)

- Thick steel (more than 1 inch thick)

9. What are the different shapes of steel that are commonly cut in a steel plant?

- Flat steel (sheets and plates)

- Round steel (bars and rods)

- Square steel (bars and tubes)

- Angle steel

- Channel steel

10. What are the different applications of cut steel in a steel plant?

- Construction

- Automotive

- Aerospace

- Energy

- Mining

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Top Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Top Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Top cutters are experts in cutting and trimming fabrics, leather, and other materials used in manufacturing clothing, footwear, and other products. They play a crucial role in ensuring the quality and precision of the final product. The key job responsibilities of a Top Cutter include:

1. Fabric Preparation:

Inspecting and measuring fabrics, leathers, and other materials to determine the appropriate cutting patterns.

Identifying and marking defects or imperfections to ensure optimal fabric utilization.

Preparing the cutting machines, ensuring proper blade sharpness and alignment.

2. Pattern Cutting:

Reading and interpreting complex cutting patterns or specifications.

Positioning and securing fabrics on the cutting table using pins, weights, or adhesives.

Operating industrial cutting machines to cut materials precisely according to the patterns, ensuring accuracy and consistency.

3. Quality Control:

Measuring and verifying the dimensions and quality of the cut pieces.

Identifying and correcting any errors or deviations from specifications.

Maintaining detailed records of cut materials and ensuring traceability for quality assurance purposes.

4. Production Optimization:

Optimizing the cutting process to minimize waste and increase efficiency.

Collaborating with designers, engineers, and production teams to ensure alignment with design specifications and production timelines.

Staying abreast of new technologies and best practices in fabric cutting.

Interview Preparation Tips

To ace an interview for a Top Cutter position, candidates can follow these tips:

1. Research the Company and Position:

Thoroughly research the specific company and the Top Cutter role to gain a comprehensive understanding of their products, processes, and expectations.

Identify the key skills, experience, and qualifications required for the position and tailor your resume and cover letter accordingly.

2. Highlight Relevant Experience:

Emphasize your experience in fabric cutting, handling, and quality control. Quantify your accomplishments with specific metrics and examples to demonstrate your proficiency.

Discuss your knowledge of industry-specific equipment, techniques, and safety protocols.

3. Demonstrate Attention to Detail:

Top Cutters are known for their precision and accuracy. During the interview, highlight your ability to work meticulously, follow instructions precisely, and identify even the smallest discrepancies.

Provide examples of situations where you have paid meticulous attention to detail, resulting in positive outcomes.

4. Showcase Problem-Solving Skills:

Interviewers may ask about how you handle unexpected challenges or errors in the cutting process. Prepare specific examples of how you have identified and resolved issues, ensuring minimal disruptions and maintaining quality standards.

Emphasize your analytical and troubleshooting abilities.

5. Prepare for Technical Questions:

Expect technical questions related to fabric properties, cutting techniques, and machine operations. Be prepared to discuss different types of fabrics, their characteristics, and how they should be handled.

Show your understanding of cutting equipment, blade sharpening, and proper maintenance procedures.

6. Practice Common Interview Questions:

Prepare for common interview questions related to your skills, experience, and motivation. Practice your answers to questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

Be confident in your responses and demonstrate your enthusiasm for the position.

7. Ask Meaningful Questions:

Asking thoughtful questions shows that you are engaged and interested in the role. Prepare questions about the company’s culture, growth opportunities, and specific projects related to fabric cutting.

This also allows you to gather more information and assess if the position and company are a good fit for you.

By following these tips, candidates can increase their chances of making a positive impression during a Top Cutter interview and demonstrating their suitability for the role.Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Top Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Top Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.