Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Top Printing Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Top Printing Press Operator so you can tailor your answers to impress potential employers.

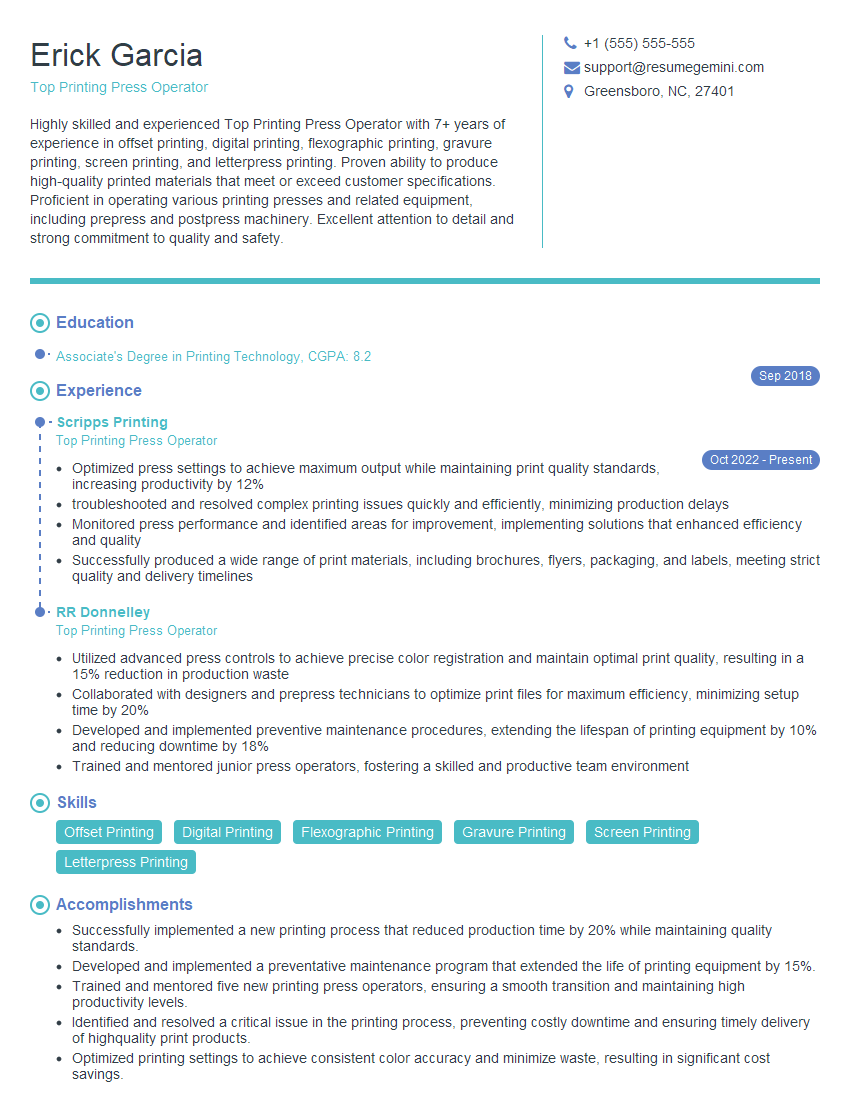

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Top Printing Press Operator

1. How would you ensure the accuracy of color reproduction during the printing process?

To ensure color accuracy during the printing process, I would implement the following measures:

- Calibrate and maintain the printing press regularly to ensure consistent color output.

- Use color profiles to match colors between the design file and the printed product.

- Proof colors before printing to verify accuracy and make necessary adjustments.

- Monitor color consistency throughout the printing run and make adjustments as needed.

- Communicate with designers and prepress professionals to ensure color expectations are met.

2. What press maintenance procedures are crucial to prevent quality issues?

Regular Maintenance Tasks

- Lubricate moving parts to reduce friction and wear.

- Clean rollers and blankets to remove ink residue and prevent ghosting.

- Inspect and replace worn or damaged parts to maintain optimal performance.

- Monitor ink levels and adjust as necessary to ensure consistent ink coverage.

- Calibrate sensors and controls to ensure accurate registration and printing quality.

Preventative Maintenance

- Conduct thorough inspections to identify potential issues early on.

- Perform scheduled maintenance based on manufacturer recommendations.

- Use high-quality consumables and spare parts to extend machine life and prevent breakdowns.

- Train operators on proper maintenance procedures to avoid incorrect handling.

- Maintain a clean and organized printing environment to minimize contamination.

3. How do you optimize press speed and efficiency without compromising quality?

To optimize press speed and efficiency without compromising quality, I would employ the following strategies:

- Use automated presetting systems to reduce makeready times.

- Fine-tune ink and water balance to minimize waste and increase productivity.

- Monitor press performance and identify areas for improvement through data analysis.

- Implement lean manufacturing principles to streamline processes and eliminate bottlenecks.

- Train operators on efficient operating techniques to reduce errors and downtime.

4. What troubleshooting techniques do you use to resolve common printing press issues?

To troubleshoot common printing press issues efficiently, I utilize the following techniques:

- Identify the problem accurately by observing symptoms and analyzing error messages.

- Refer to technical manuals and consult with experienced colleagues for guidance.

- Perform systematic troubleshooting steps, starting with the most likely causes.

- Use diagnostic tools and tests to pinpoint the faulty component or setting.

- Implement corrective actions and verify the resolution by testing the press again.

5. How do you handle complex printing projects that require multiple passes or special techniques?

When handling complex printing projects, I follow a structured approach:

- Thoroughly review the project specifications and identify any special requirements.

- Plan the printing process carefully, including the order of passes and the use of specialized techniques.

- Set up the press accurately and ensure precise registration for multi-pass printing.

- Monitor the printing process closely and make adjustments as needed to maintain quality.

- Communicate with the customer throughout the process to keep them informed and address any concerns.

6. What quality control measures do you implement to ensure the accuracy and consistency of printed products?

To ensure the accuracy and consistency of printed products, I implement the following quality control measures:

- Establish and follow clear quality standards and specifications.

- Inspect incoming materials and consumables to verify their quality.

- Proof and inspect printed samples regularly throughout the printing process.

- Use measuring and testing equipment to ensure dimensional accuracy and color consistency.

- Document and track quality control data to identify trends and areas for improvement.

7. How do you ensure safety and minimize risks while operating printing presses?

To ensure safety and minimize risks while operating printing presses, I adhere to the following practices:

- Wear appropriate personal protective equipment, including earplugs and safety glasses.

- Follow established safety protocols and lockout/tagout procedures.

- Inspect the press and work area before each use to identify potential hazards.

- Keep the work area clean and organized to prevent tripping and other accidents.

- Receive regular training on safety procedures and emergency response.

8. What techniques do you use to minimize waste and maximize efficiency in ink usage?

To minimize waste and maximize efficiency in ink usage, I employ the following techniques:

- Calibrate the press accurately to ensure optimal ink transfer.

- Use high-quality inks and consumables to reduce waste and improve print quality.

- Monitor ink levels and adjust as needed to avoid overinking or running out.

- Recycle and reuse waste ink whenever possible.

- Implement lean manufacturing principles to streamline processes and eliminate unnecessary waste.

9. How do you stay up-to-date with the latest printing technologies and advancements?

To stay up-to-date with the latest printing technologies and advancements, I engage in the following activities:

- Attend industry trade shows and conferences.

- Read trade publications and online resources.

- Participate in online forums and discussions.

- Network with other printing professionals.

- Attend training and development programs offered by equipment manufacturers and industry organizations.

10. What are your strengths and weaknesses as a printing press operator?

My strengths as a printing press operator include:

- Expertise in operating a wide range of printing presses.

- Strong attention to detail and commitment to quality.

- Ability to troubleshoot and resolve printing issues efficiently.

- Excellent communication and interpersonal skills.

Areas where I seek to improve include:

- Expanding my knowledge of digital printing technologies.

- Developing expertise in color management and profiling.

- Enhancing my leadership and supervisory skills.

I am confident that I can leverage my strengths and address my areas of improvement to excel in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Top Printing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Top Printing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Top Printing Press Operator is responsible for the entire printing process, from prepress to finishing. They must have a thorough understanding of printing presses, papers, and inks, and be able to troubleshoot problems that may arise during the printing process.

The key job responsibilities of a Top Printing Press Operator include:

1. Prepress

The prepress process involves preparing the files that will be printed on the press. This includes creating the layout of the pages, selecting the fonts and images, and preparing the files for printing.

- Work with customers to determine their printing needs.

- Create and prepare digital files for printing.

- Proofread and correct errors in digital files.

- Select and prepare printing plates.

2. Press Operations

The press operator is responsible for operating the printing press and ensuring that the printed products meet the customer’s specifications.

- Operate and maintain printing presses.

- Monitor the printing process and make adjustments as needed.

- Troubleshoot and resolve printing problems.

- Ensure that the printed products meet the customer’s specifications.

3. Finishing

The finishing process involves the final steps of the printing process, such as cutting, folding, and binding the printed products.

- Cut and fold printed products.

- Bind printed products.

- Package and ship printed products.

Interview Tips

Preparing for an interview for a Top Printing Press Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read about the company’s products or services.

- Learn about the company’s history and culture.

- Review the job description carefully.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Tailor your answers to the specific job you are applying for.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the printing industry. Be prepared to talk about your skills and knowledge, and how you have used them to succeed in your previous roles.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your experience.

- Be enthusiastic and positive when talking about your experience.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture.

- Ask about the company’s plans for the future.

- Ask about the specific responsibilities of the position.

By following these tips, you can increase your chances of success in the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Top Printing Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.