Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Torch Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

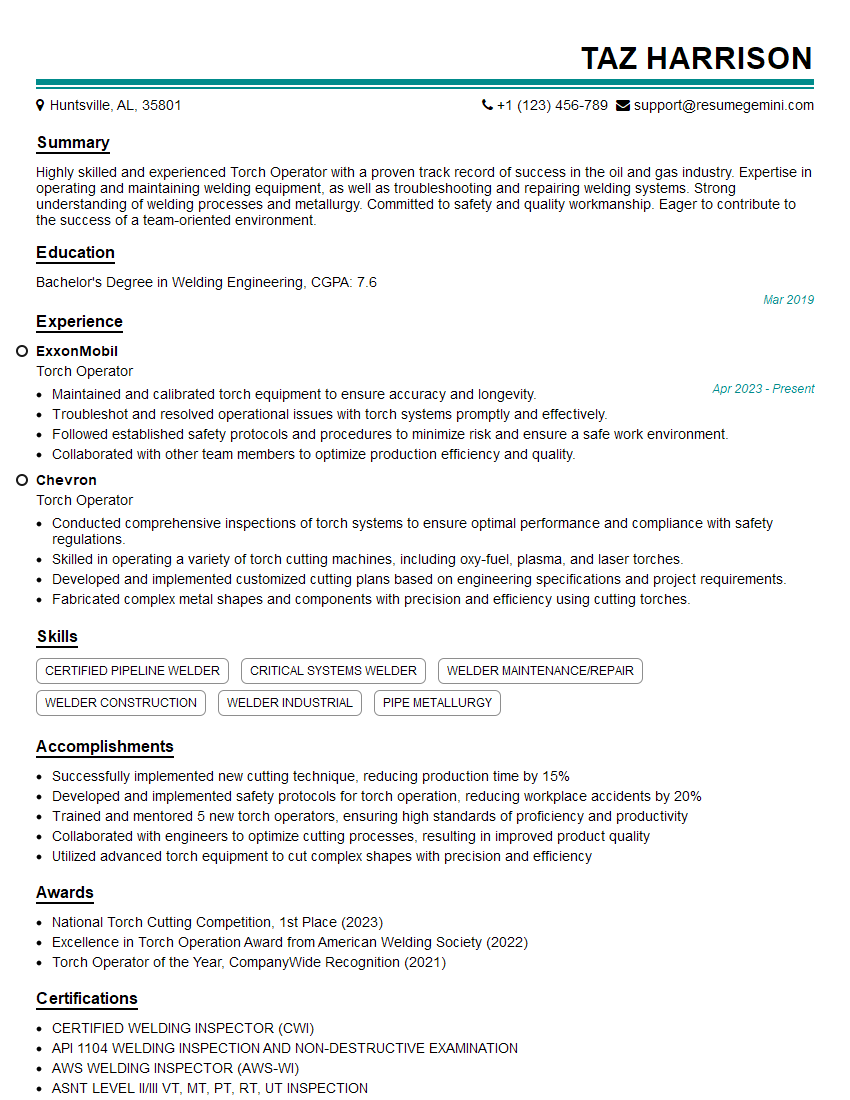

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Torch Operator

1. Explain the role of a torch operator and its responsibilities.

As a torch operator, my key responsibilities include:

- Operating and maintaining complex torch cutting equipment

- Reading and interpreting blueprints and specifications

- Setting up workpieces and materials for cutting

- Monitoring the cutting process and making adjustments as needed

- Ensuring compliance with safety protocols and industry standards

2. What are the different types of torch cutting processes?

The main types of torch cutting processes are:

Oxy-fuel cutting

- Uses a mixture of oxygen and a fuel gas (typically acetylene or propane)

- Suitable for cutting ferrous metals

Plasma arc cutting

- Uses a plasma torch to generate a high-temperature plasma

- Cuts through a wide range of materials, including stainless steel and aluminum

Laser cutting

- Uses a laser beam to cut through materials

- Provides high precision and clean cuts

3. What are the safety precautions that must be taken when operating a torch cutting machine?

To ensure safety during torch cutting operations, it is crucial to adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and fire-resistant clothing

- Inspect the equipment before use and ensure it is in good working condition

- Secure the workpiece to prevent movement during cutting

- Ventilate the work area to prevent gas accumulation

- Keep flammable materials away from the cutting area

4. Describe the process of setting up and operating an oxy-fuel cutting torch.

Setting up and operating an oxy-fuel cutting torch involves the following steps:

- Attach the cutting torch to the gas supply lines (oxygen and fuel)

- Adjust the gas pressures according to the material being cut

- Light the torch and adjust the flame to the desired size and shape

- Position the torch tip at the starting point of the cut

- Ignite the cutting oxygen and begin cutting

- Guide the torch along the cut line, maintaining a consistent distance from the workpiece

5. How do you maintain and troubleshoot a torch cutting machine?

To maintain and troubleshoot a torch cutting machine:

- Regularly inspect and clean the torch head, nozzles, and hoses

- Check the gas pressures and flow rates to ensure they are within specifications

- Lubricate moving parts as per the manufacturer’s guidelines

- Troubleshoot common issues such as clogged nozzles, unstable flames, and poor cut quality

6. What are the different factors that affect the quality of a torch cut?

The quality of a torch cut is influenced by several factors, including:

- Material thickness and type

- Cutting speed and gas flow rates

- Torch tip size and condition

- Angle of the torch to the workpiece

- Operator skill and experience

7. Explain the use of jigs and fixtures in torch cutting.

Jigs and fixtures are essential for ensuring accuracy and repeatability in torch cutting operations. They serve the following purposes:

- Hold the workpiece securely in place

- Guide the torch along the desired cutting path

- Control the depth and angle of the cut

- Improve productivity and reduce setup time

8. What are the advantages and disadvantages of using a CNC torch cutting machine?

Advantages

- Increased precision and accuracy

- Faster cutting speeds and higher productivity

- Reduced material waste

- Automation of cutting processes

Disadvantages

- Higher initial investment cost

- Requires skilled operators for programming and maintenance

- Limited flexibility compared to manual cutting

9. How do you handle scrap metal generated from torch cutting operations?

Scrap metal from torch cutting must be handled responsibly to minimize environmental impact and maximize resource utilization:

- Sort and segregate different types of metals (e.g., ferrous, non-ferrous)

- Store scrap metal in designated areas to prevent contamination

- Recycle scrap metal through authorized recycling facilities

10. Describe a challenging torch cutting project you have worked on and how you overcame the challenges.

In a previous role, I encountered a project that involved cutting intricate shapes from thick stainless steel plate. The challenge lay in achieving clean and precise cuts without distorting the material. I overcame this by:

- Using a high-quality plasma arc cutting machine

- Optimizing cutting parameters and gas flow rates

- Employing a water table to minimize heat distortion

- Post-processing the cut pieces to remove any burrs or imperfections

- This approach resulted in high-quality cuts that met the project specifications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Torch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Torch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Torch Operator plays a crucial role in industrial settings, utilizing specialized equipment to cut, weld, and manipulate metals.

1. Cutting and Shaping Metals

Using various cutting torches, such as oxy-acetylene and plasma torches, to precision-cut and shape metal components.

- Reading and interpreting blueprints and specifications to determine cutting parameters.

- Ensuring precise cuts, bevels, and angles to meet design requirements.

2. Welding and Fabrication

Employing welding techniques, such as arc welding and gas welding, to join metal components securely.

- Selecting appropriate welding equipment and materials based on the job requirements.

- Performing welding operations to create durable and functional structures.

3. Maintenance and Repair

Maintaining and repairing machinery, equipment, and pipelines, ensuring optimal performance.

- Inspecting equipment regularly for any signs of wear or damage.

- Performing preventive maintenance tasks, such as lubrication and cleaning.

4. Safety Compliance

Adhering to strict safety regulations and guidelines to ensure a safe work environment.

- Wearing appropriate personal protective equipment, including welding masks, gloves, and protective clothing.

- Following established safety procedures to prevent accidents and injuries.

Interview Tips

To ace your Torch Operator interview, consider these preparation tips and demonstrate your skills:

1. Research the Industry and Company

Familiarize yourself with the company’s products, services, and industry trends. Research industry-related news and developments to show your interest and knowledge.

- Example: Discuss recent advancements in welding techniques or safety regulations.

- Example: Highlight your understanding of the company’s specific cutting and welding applications.

2. Emphasize Your Technical Skills

Showcase your proficiency in torch cutting, welding, and fabrication techniques. Provide specific examples of projects you’ve completed and the challenges you overcame.

- Example: Describe a complex cutting operation you executed with precision and accuracy.

- Example: Share your experience in welding different types of metals, explaining the challenges and techniques involved.

3. Highlight Safety and Regulations Knowledge

Emphasize your commitment to safety by demonstrating your understanding of industry regulations and best practices. Explain how you prioritize safety in your work.

- Example: Discuss your knowledge of the Occupational Safety and Health Administration (OSHA) regulations for welding and torch operations.

- Example: Describe how you conduct regular safety inspections and follow established procedures to prevent accidents.

4. Prepare for Behavioral Interview Questions

Be prepared to answer questions that assess your problem-solving, teamwork, and communication skills. Provide examples from your past experiences that demonstrate your abilities.

- Example: Describe a situation where you encountered a difficulty during a cutting or welding operation and how you successfully resolved it.

- Example: Explain how you effectively collaborate with colleagues in a team environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Torch Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.