Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Torque Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

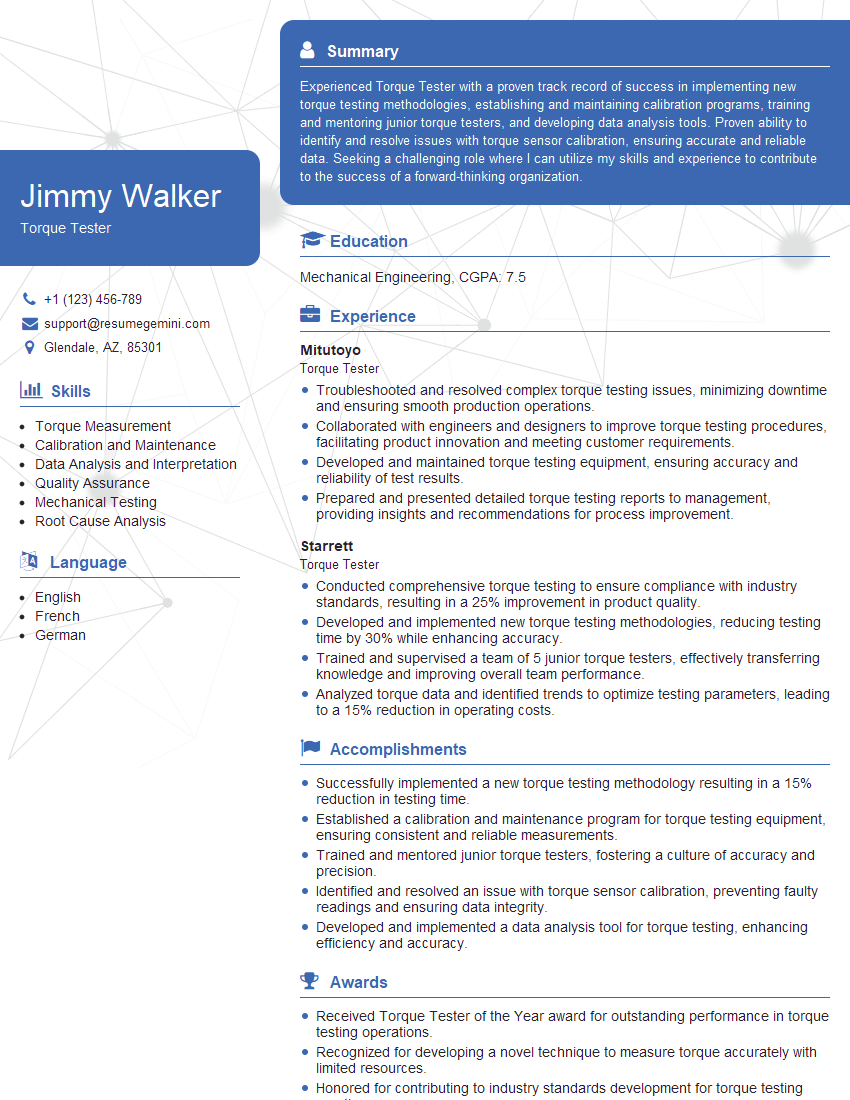

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Torque Tester

1. What is the difference between torque and torque linearity?

- Torque is the turning force applied to an object around an axis.

- Torque linearity is the degree to which the torque applied to an object is proportional to the resulting angular acceleration.

2. What are the different types of torque transducers?

Strain Gauge Torque Transducers

- Strain gauge torque transducers measure torque by measuring the strain in a strain gauge that is bonded to a shaft.

- They are relatively inexpensive and have a high accuracy.

Eddy Current Torque Transducers

- Eddy current torque transducers measure torque by measuring the eddy currents that are induced in a conductive disc when it is rotated in a magnetic field.

- They are non-contact and have a high bandwidth.

Optical Torque Transducers

- Optical torque transducers measure torque by measuring the deflection of a light beam that is reflected off of a mirror that is attached to a shaft.

- They are non-contact and have a very high resolution.

3. What are the important specifications that should be considered when selecting a torque transducer?

- Torque range

- Accuracy

- Resolution

- Bandwidth

- Environmental conditions

4. What are the common sources of error in torque measurements?

- Misalignment between the torque transducer and the shaft

- Eccentricity of the shaft

- Temperature effects

- Electrical noise

5. What are the different methods that can be used to calibrate a torque transducer?

- Deadweight calibration

- Strain gauge calibration

- Eddy current calibration

- Optical calibration

6. What are the different applications of torque transducers?

- Engine testing

- Transmission testing

- Driveline testing

- Industrial automation

- Robotics

7. What are the challenges involved in designing and manufacturing torque transducers?

- Achieving high accuracy and resolution

- Minimizing errors due to misalignment and eccentricity

- Compensating for temperature effects

- Designing for a wide range of applications

8. What are the future trends in torque transducer technology?

- Increased use of wireless technology

- Development of new materials with improved properties

- Integration of sensors and electronics

- Development of new applications

9. What are the key factors to consider when selecting a torque transducer for a specific application?

- Torque range

- Accuracy

- Resolution

- Bandwidth

- Environmental conditions

- Cost

10. What are the common maintenance procedures that are required for torque transducers?

- Calibration

- Cleaning

- Lubrication

- Inspection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Torque Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Torque Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Torque Tester is responsible for testing and ensuring the quality of various products by measuring and evaluating their torque properties. The primary objective of this role is to ensure that products meet the required torque specifications and quality standards.

1. Testing and Evaluation

Conduct torque tests on different types of products to determine their torque characteristics and compliance with specifications.

- Operate torque testing equipment such as torque wrenches, torque meters, and test benches.

- Document and analyze test results, including torque measurements, test parameters, and observations.

2. Data Analysis and Reporting

Interpret test results and identify potential issues or deviations from specifications.

- Prepare test reports summarizing the results of the torque evaluations.

- Communicate findings and recommendations to relevant stakeholders, including engineers, quality control personnel, and management.

3. Quality Control

Assist in establishing and maintaining quality control standards and procedures related to torque testing.

- Calibrate and maintain torque testing equipment to ensure accurate and reliable measurements.

- Participate in quality audits and assessments to evaluate the effectiveness of torque testing processes.

4. Troubleshooting and Problem-Solving

Identify and resolve issues related to torque testing, equipment malfunctions, or product defects.

- Analyze test results and identify potential causes of non-conformance.

- Recommend corrective actions to improve torque performance and product quality.

Interview Tips

1. Research the Company and Position

Research the company’s website, industry publications, and social media to gain insights into their operations, culture, and the specific role you’re applying for.

- Identify the company’s mission statement, values, and products or services.

- Learn about the specific requirements and responsibilities of the Torque Tester position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in torque testing and your familiarity with industry standards and best practices. Quantify your accomplishments and provide specific examples of your work.

- Describe your proficiency in using torque testing equipment and your ability to interpret test results.

- Mention any certifications or training programs you’ve completed related to torque testing.

3. Demonstrate Problem-Solving Abilities

Highlight your ability to troubleshoot issues with torque testing equipment or product defects. Explain how you approach problem-solving and provide examples of successful outcomes.

- Describe a situation where you identified and resolved a problem with a torque testing machine.

- Explain the steps you took to analyze the issue and determine the root cause.

4. Articulate Your Quality-Focused Approach

Emphasize your understanding of quality control principles and your commitment to delivering high-quality products. Explain how you contribute to quality improvement and ensure compliance with industry standards.

- Discuss your role in establishing and maintaining quality control standards for torque testing.

- Mention your involvement in quality audits and your suggestions for process improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Torque Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!