Are you gearing up for an interview for a Tower Crane Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tower Crane Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

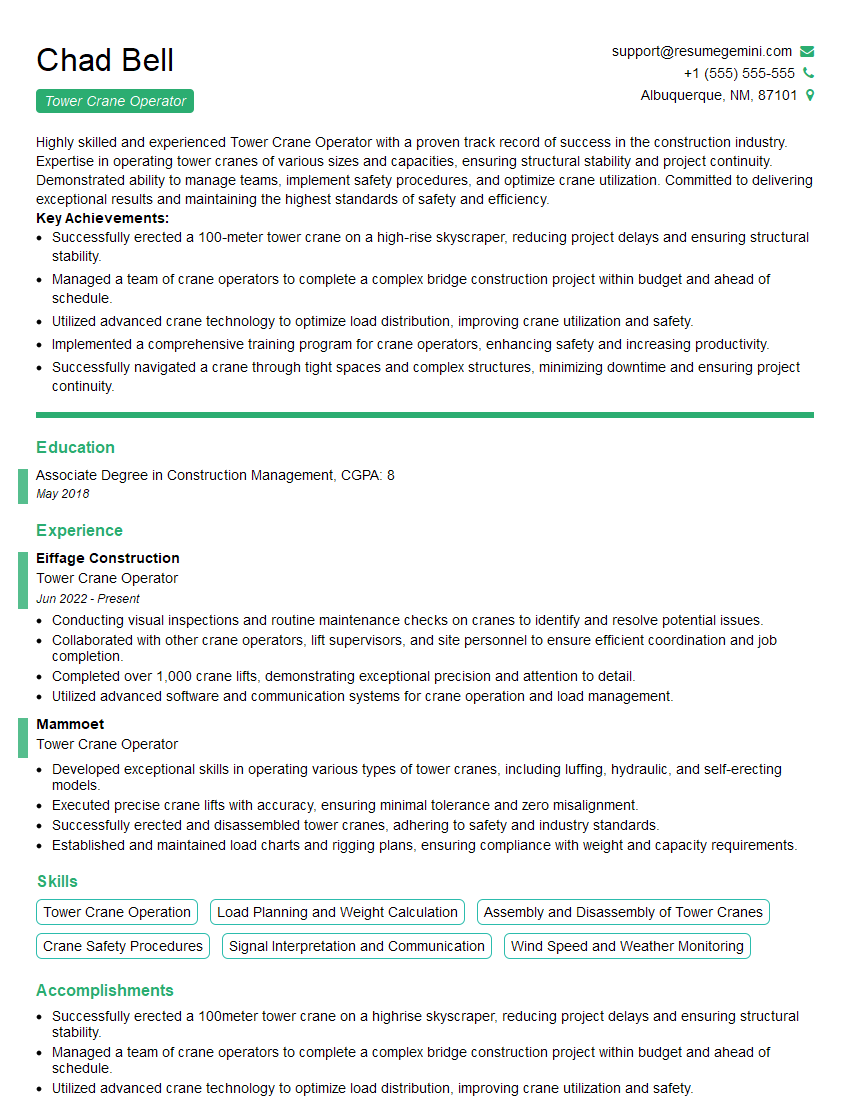

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tower Crane Operator

1. What are the different types of tower cranes and their uses?

There are several types of tower cranes used in construction, each designed for specific purposes:

- Self-Erecting Cranes: These cranes can be assembled and dismantled by the operator without the need for external assistance. They are often used for smaller projects or in areas with limited space.

- Topkit Cranes: These cranes have a fixed tower height and a luffing jib. They are typically used for medium-sized projects and can be configured to handle various loads and heights.

- Derrick Cranes: These cranes have a stationary tower and a movable boom. They are often used for heavy lifting operations, such as in bridge construction or wind turbine installation.

- Hammerhead Cranes: These cranes have a horizontal jib that extends beyond the tower. They are commonly used in shipyards and industrial facilities for handling large and heavy materials.

- Offshore Cranes: These cranes are designed for use on offshore platforms and vessels. They are specialized for marine environments and can withstand harsh weather conditions.

2. Describe the major components of a tower crane and their functions.

Tower and Base

- Supports the crane and provides stability

- Base distributes the crane’s weight evenly

Jib and Hoist

- Jib carries the hook and load

- Hoist raises and lowers the load

Slewing Mechanism

- Rotates the crane’s superstructure

- Allows for positioning the load

Counterweight

- Balances the crane’s weight

- Prevents the crane from tipping over

Control System

- Operates the crane’s functions

- Ensures safe and precise load handling

3. What are the key safety considerations for operating a tower crane?

Operating a tower crane requires strict adherence to safety protocols:

- Load Limits: Never exceed the crane’s rated capacity for any given configuration.

- Weather Conditions: Do not operate the crane during high winds or severe weather.

- Signal Person: Always have a qualified signal person to guide the crane operator.

- Communication: Maintain clear and effective communication with ground crew and other workers.

- Inspection and Maintenance: Regularly inspect and maintain the crane to ensure optimal performance and safety.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including a hard hat, safety harness, and gloves.

4. How do you assess the load capacity of a tower crane?

Assessing the load capacity of a tower crane involves considering several factors:

- Crane’s Load Chart: Refer to the manufacturer’s load chart for the crane’s specific specifications.

- Crane Configuration: The crane’s configuration, including the jib length, radius, and boom angle, affects its load capacity.

- Load Weight: Accurately determine the weight of the load to be lifted.

- Environmental Conditions: Wind speed, temperature, and humidity can impact the crane’s load capacity.

- Operator Experience: The crane operator’s skill and experience can influence the crane’s safe operation within its load capacity.

5. Describe the pre-operational checks you perform before operating a tower crane.

Thorough pre-operational checks are crucial for safe and efficient crane operation:

- Visual Inspection: Inspect the crane, jib, hook, and cables for any damage or defects.

- Safety Devices: Ensure that all safety devices, such as limit switches and emergency stops, are functioning correctly.

- Hydraulic Oil and Lubrication: Check fluid levels and lubricate moving parts as per the manufacturer’s recommendations.

- Electrical System: Test electrical connections and ensure that the control system is operating properly.

- Communication System: Verify that the communication system with the signal person is clear and reliable.

6. How do you handle load instability and wind effects while operating a tower crane?

Load Instability

- Identify the cause: Determine if the load is unbalanced, improperly rigged, or experiencing external forces.

- Re-stabilize the load: Carefully adjust the crane’s position and use the hoist to stabilize the load.

- Seek assistance: If unable to stabilize the load alone, request assistance from the signal person or ground crew.

Wind Effects

- Monitor wind speed: Pay attention to weather forecasts and use anemometers to monitor wind conditions.

- Reduce sail area: Lower the jib or luff the crane into the wind to minimize wind resistance.

- Secure the load: Ensure that the load is securely attached to the hook and is not swaying.

7. Explain the importance of counterweight for stability in tower cranes.

Counterweight plays a crucial role in maintaining the stability of tower cranes by:

- Balancing the Crane: The counterweight counteracts the weight of the jib, load, and any other unbalanced forces acting on the crane.

- Preventing Overturning: The weight of the counterweight prevents the crane from tipping over or collapsing under the load.

- Adjusting Load Capacity: By adding or removing counterweight, the crane’s load capacity can be adjusted to suit different lifting requirements.

8. Describe the different methods used for slewing a tower crane.

- Manual Slewing: The crane’s superstructure is rotated using a handwheel or lever.

- Electric Slewing: An electric motor powers the slewing mechanism for smooth and precise rotation.

- Hydraulic Slewing: Hydraulic cylinders provide power for slewing, offering greater control and torque.

9. Explain the purpose and operation of a luffing jib on a tower crane.

A luffing jib allows the operator to adjust the angle of the jib:

- Height Adjustment: The jib can be raised or lowered to reach different heights.

- Wind Mitigation: Luffing the jib into the wind reduces wind resistance and improves stability.

- Clearance: It allows the crane to clear obstacles or work under confined spaces.

- Load Handling: Luffing the jib can improve load control and precision during placement.

10. Describe the role of technology in modern tower crane operation.

- Load Monitoring Systems: Monitor load weight and prevent overloading.

- Anti-Collision Systems: Detect potential collisions and alert the operator.

- Remote Control and Monitoring: Allow for remote operation and real-time crane performance monitoring.

- Wind Measurement Devices: Provide accurate wind speed readings for safe operation.

- Data Logging and Analytics: Record crane performance data for analysis and improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tower Crane Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tower Crane Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tower Crane Operators play a pivotal role in construction projects, ensuring the safe and efficient movement of heavy materials and equipment. Their key responsibilities encompass:

1. Crane Operation

Skilled operation of tower cranes, including control of all crane functions (e.g., hoisting, luffing, slewing).

- Precise placement of loads at designated locations.

- Compliance with safety protocols and regulations.

2. Load Handling

Safe and secure handling of construction materials and equipment, adhering to weight and balance considerations.

- Coordination with signalers and ground crew for proper load placement.

- Inspection of loads for stability and integrity.

3. Site Assessment and Planning

Thorough assessment of the construction site, including obstacles and potential hazards.

- Review of crane specifications and site layout plans.

- Coordination with project managers and engineers to determine optimal crane placement and operation.

4. Maintenance and Inspection

Regular maintenance and inspection of the crane, ensuring optimal performance and safety.

- Lubrication, adjustment, and cleaning of crane components.

- Identification and timely reporting of any maintenance issues or concerns.

Interview Tips

To ace the interview for a Tower Crane Operator position, candidates should prepare thoroughly and consider the following tips:

1. Research the Company and Role

Delve into the company’s history, projects, and safety protocols. This demonstrates your interest and knowledge of the organization.

- Review industry publications and news articles to stay informed about the latest trends and advancements.

- Attend industry events and workshops to expand your network and enhance your skills.

2. Highlight Relevant Experience and Qualifications

Emphasize your experience in operating tower cranes and handling heavy loads. Quantify your accomplishments and provide specific examples.

- Discuss any certifications or licenses you hold, such as CCO (Certified Crane Operator) or NCCCO (National Commission for the Certification of Crane Operators).

- Showcase your knowledge of crane safety regulations and best practices.

3. Demonstrate Safety Consciousness

Emphasize your unwavering commitment to safety. Tower Crane Operators bear a significant responsibility for the safety of others on the construction site.

- Describe your understanding of the potential hazards associated with crane operation.

- Explain how you mitigate risks and ensure the safety of colleagues and equipment.

4. Practice Your Responses

Prepare thoughtful answers to common interview questions. This will help you articulate your skills, experience, and enthusiasm for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Consider questions about teamwork, problem-solving, and decision-making under pressure.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately and arrive on time for the interview. This conveys your respect for the company and the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tower Crane Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.