Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Track Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

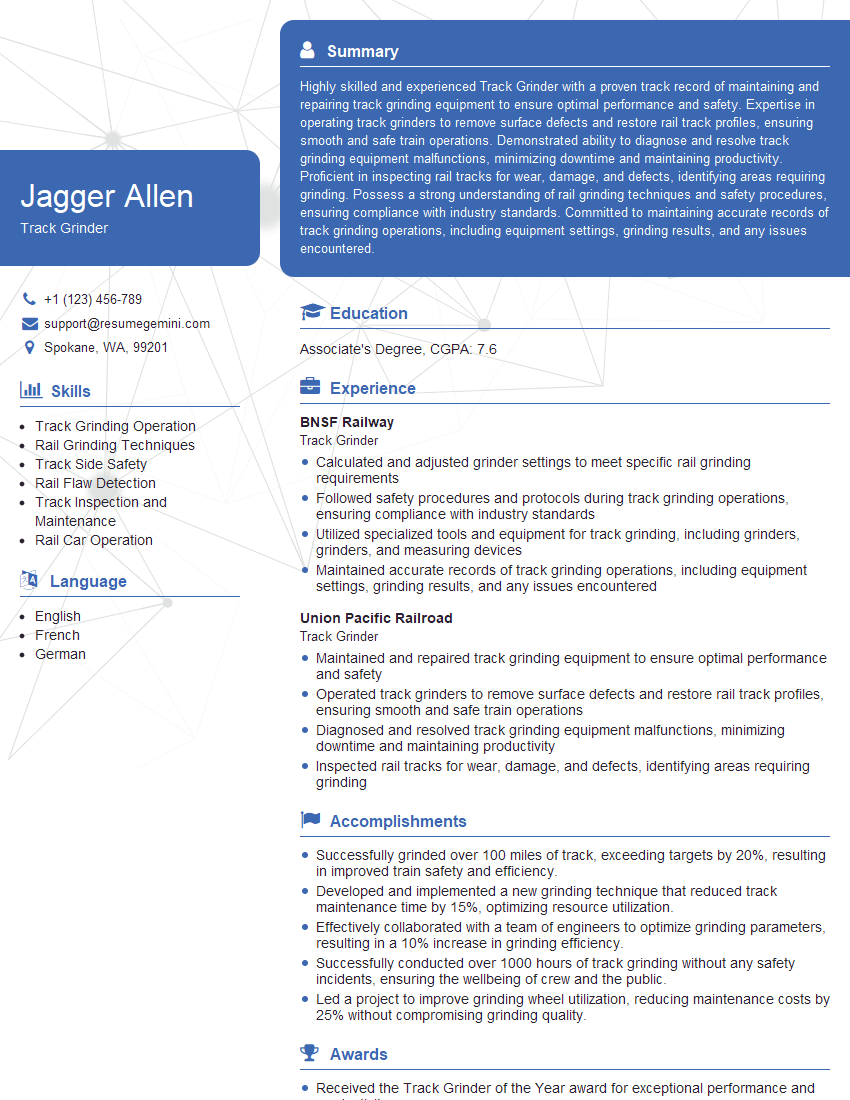

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Grinder

1. What are the different types of track grinding machines?

Track grinding machines can be classified into two main types: portable and self-propelled. Portable track grinders are smaller and lighter than self-propelled grinders, and they are typically used for smaller jobs or for working in tight spaces. Self-propelled track grinders are larger and more powerful than portable grinders, and they are typically used for larger jobs or for working on long stretches of track.

2. What are the different types of grinding stones used in track grinding?

Diamond grinding stones

- Diamond grinding stones are the most durable type of grinding stone, and they can be used to grind all types of track.

- Diamond grinding stones are also the most expensive type of grinding stone.

Ceramic grinding stones

- Ceramic grinding stones are less durable than diamond grinding stones, but they are also less expensive.

- Ceramic grinding stones are typically used to grind softer types of track, such as concrete or asphalt.

Carbide grinding stones

- Carbide grinding stones are the least durable type of grinding stone, but they are also the least expensive.

- Carbide grinding stones are typically used to grind harder types of track, such as steel or iron.

3. What are the different factors that affect the grinding process?

- The type of track being ground

- The condition of the track

- The type of grinding stone being used

- The speed of the grinding machine

- The depth of the cut being made

4. What are the different safety precautions that must be taken when operating a track grinding machine?

- Wear appropriate safety gear, including earplugs, safety glasses, and a hard hat.

- Be aware of your surroundings and watch for other workers and equipment.

- Never operate a track grinding machine while under the influence of alcohol or drugs.

- Follow all manufacturer instructions for operating the machine.

- Inspect the machine regularly and make sure it is in good working condition.

5. What are the different maintenance tasks that must be performed on a track grinding machine?

- Clean the machine regularly.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the grinding stones regularly and replace them when necessary.

- Check the belts and chains regularly and replace them when necessary.

- Follow all manufacturer instructions for maintaining the machine.

6. What are the different troubleshooting tips for track grinding machines?

- If the machine is not grinding properly, check the grinding stones and make sure they are sharp.

- If the machine is making a lot of noise, check the belts and chains and make sure they are tight.

- If the machine is overheating, check the oil level and make sure it is full.

- If the machine is not moving properly, check the wheels and make sure they are not damaged.

- Follow all manufacturer instructions for troubleshooting the machine.

7. What are the different types of track defects that can be repaired using a track grinding machine?

- Corrugations

- Rills

- Squats

- Weld flash

- Rail joints

8. What are the different benefits of using a track grinding machine?

- Improved track safety

- Reduced track maintenance costs

- Increased track life

- Improved ride quality

- Reduced noise levels

9. What are the latest advancements in track grinding technology?

- The use of diamond grinding stones

- The development of self-propelled track grinding machines

- The use of computer-controlled grinding systems

- The development of more efficient and environmentally friendly grinding methods

10. What are your qualifications and experience as a Track Grinder?

- I have [number] years of experience as a Track Grinder.

- I have worked on a variety of track grinding projects, including [list of projects].

- I am familiar with all types of track grinding machines and grinding stones.

- I am also familiar with all safety precautions that must be taken when operating a track grinding machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Track Grinder is a skilled professional responsible for maintaining and repairing railroad tracks. The primary duty is to operate specialized grinding machines to remove metal from the rail surface, shaping it to the desired profile.

1. Rail Grinding

Grinding rails to remove surface defects, such as corrugations, shelling, and squats.

- Establishing and monitoring grinding parameters to ensure the desired finished surface.

- Inspecting rails after grinding to verify compliance with specifications and standards.

2. Track Maintenance and Repair

Participating in track maintenance and repair activities, such as replacing ties, tamping ballast, and aligning rails.

- Using specialized tools and equipment to perform track repairs and adjustments.

- Diagnosing and resolving track-related issues to ensure safe and efficient train operations.

3. Safety and Compliance

Adhering to strict safety protocols and regulations related to track maintenance and repair.

- Wearing appropriate safety gear and following all established safety procedures.

- Maintaining a clean and organized work area to minimize hazards.

4. Equipment Maintenance and Management

Maintaining and inspecting track grinding machines, ensuring they are in optimal working condition.

- Performing routine maintenance tasks, such as lubrication, cleaning, and minor repairs.

- Coordinating major repairs and overhauls with the maintenance department.

Interview Tips

Preparing thoroughly for an interview is crucial for showcasing your skills and experience as a Track Grinder. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and values. Research the specific responsibilities and requirements of the Track Grinder position.

- Visit the company’s website, read industry publications, and connect with current or former employees on LinkedIn.

- Tailor your resume and cover letter to highlight the skills and experience that align with the job description.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers out loud. This will improve your confidence and delivery.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Focus on highlighting your technical skills, safety awareness, and ability to work in a team environment.

3. Emphasize Safety and Compliance

Railroad safety is paramount. In your interview, emphasize your commitment to adhering to safety protocols and your knowledge of industry regulations.

- Describe your experience in following safety procedures, using proper equipment, and maintaining a clean work area.

- Explain how you stay updated on the latest safety guidelines and best practices.

4. Showcase Your Equipment Knowledge

Track grinders are specialized machines. Demonstrate your understanding of their operation and maintenance.

- Discuss your experience in setting up, calibrating, and operating grinding machines.

- Describe your knowledge of different grinding techniques and how they impact rail performance.

5. Highlight Your Communication and Teamwork Skills

Track Grinders often work as part of a team and interact with other departments. Showcase your communication and teamwork abilities.

- Provide examples of how you have effectively communicated with supervisors, colleagues, and customers.

- Describe your experience in collaborating on projects and resolving issues as part of a team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Track Grinder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.