Are you gearing up for an interview for a Track Grinder Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Track Grinder Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

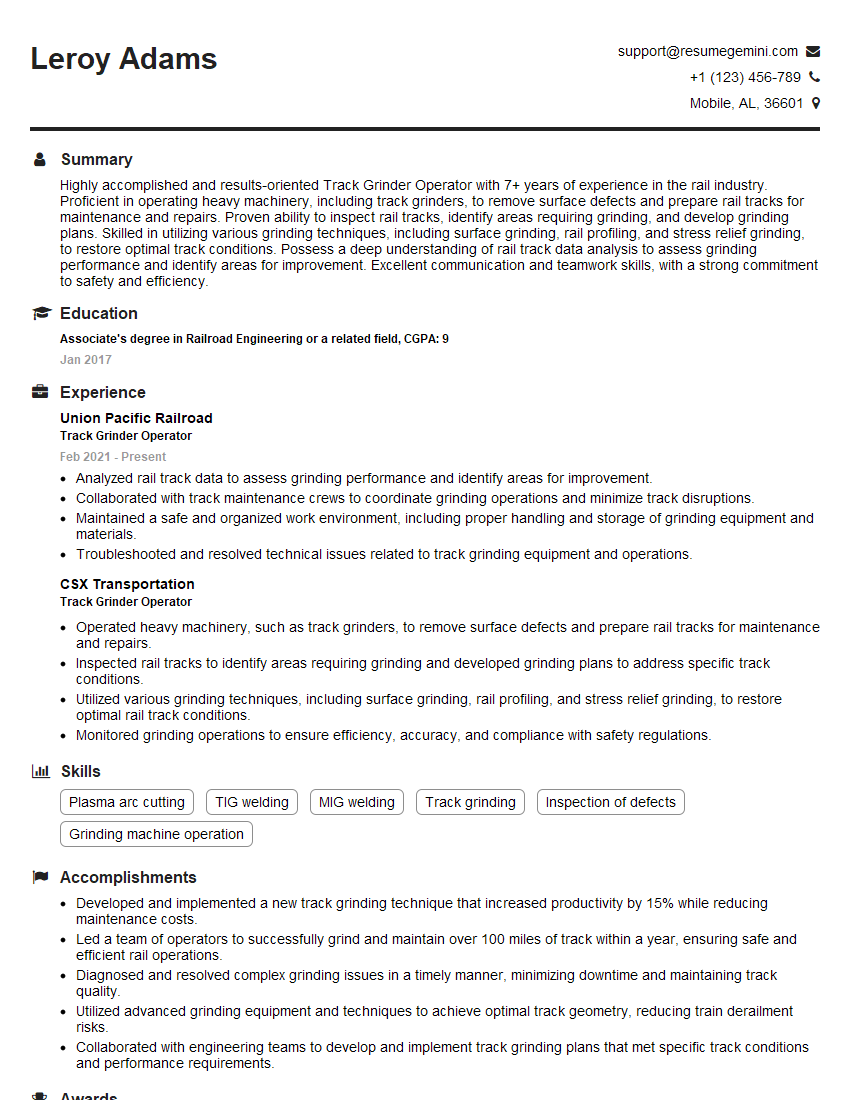

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Grinder Operator

1. Describe the process of leveling the track using a grinding machine?

The process of leveling the track using a grinding machine involves the following steps:

- The grinding machine is positioned on the track at the desired location.

- The grinding head is lowered and rotated to contact the track surface.

- The grinding head is then moved along the track, removing material from the surface.

- The process is repeated until the track surface is level.

2. What are the different types of grinding wheels used in track grinding?

Diamond wheels:

- Diamond wheels are the most common type of grinding wheel used in track grinding due to their exceptional wear resistance and cutting ability.

- They are designed to grind hard materials such as rail steel and concrete.

Ceramic wheels:

- Ceramic wheels are another type of grinding wheel commonly used in track grinding.

- They are made from a mixture of ceramics and abrasives, resulting in a durable and high-performance wheel.

3. How do you determine the correct grinding speed and depth of cut for a given track condition?

- The correct grinding speed and depth of cut depend on the condition of the track and the desired outcome.

- Factors to consider include the hardness of the rail steel, the amount of material to be removed, and the surface finish requirements.

- Test runs may be necessary to determine the optimal settings for a particular track condition.

4. What are the safety precautions that should be taken when operating a track grinder?

Safety precautions when operating a track grinder include:

- Ensuring the machine is in good working condition before use.

- Wearing appropriate personal protective equipment, including hard hat, safety glasses, earplugs, and gloves.

- Maintaining a safe distance from the grinding head and other moving parts.

- Being aware of surroundings and potential hazards, such as overhead obstacles and moving trains.

5. How do you troubleshoot common problems that may occur during track grinding?

Common problems that may occur during track grinding include:

- Premature wheel wear: This can be caused by incorrect grinding parameters, improper wheel selection, or hard spots in the rail steel.

- Excessive sparking: This can be caused by high grinding speeds, improper wheel dressing, or contamination of the grinding surface.

- Rough surface finish: This can be caused by using worn or damaged grinding wheels, incorrect grinding parameters, or poor machine alignment.

6. Describe the maintenance procedures for a track grinding machine?

Maintenance procedures for a track grinding machine include:

- Regular cleaning and inspection of the machine.

- Lubricating moving parts according to the manufacturer’s recommendations.

- Replacing worn or damaged parts as necessary.

- Performing periodic calibrations and adjustments to ensure optimal performance.

7. How do you plan and prepare for a track grinding project?

Planning and preparation for a track grinding project include:

- Assessing the condition of the track and determining the scope of work.

- Selecting the appropriate grinding equipment and tooling.

- Scheduling the work and coordinating with other departments, such as track maintenance and train operations.

- Obtaining necessary permits and approvals.

8. What are the different types of rail defects that can be detected using a grinding machine?

Different types of rail defects that can be detected using a grinding machine include:

- Corrugation: A regular series of waves on the rail surface.

- Spalling: Flaking or chipping of the rail surface.

- Head checks: Cracks that develop in the running surface of the rail.

- Squats: Depressions in the rail surface.

9. How do you measure and document the results of a track grinding project?

- The results of a track grinding project can be measured and documented through various methods:

- Using a track geometry measurement system to assess the track profile, alignment, and surface roughness.

- Performing visual inspections to identify any remaining defects or irregularities.

- Taking measurements of the grinding wheel wear and the amount of material removed from the track surface.

10. What are the advancements in track grinding technology that you are aware of?

- The advancements in track grinding technology include:

- The development of new grinding wheel materials and technologies that improve grinding efficiency and reduce wheel wear.

- The use of sensors and data analytics to optimize grinding parameters and monitor machine performance.

- The development of autonomous track grinding machines that can operate with minimal human intervention.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Track Grinder Operators are responsible for maintaining rail systems by grinding rails to remove surface defects and restore their smooth profile.

1. Operating Track Grinding Equipment

Operate track grinding machines to remove surface defects, such as corrugations, squats, and head checks.

- Set up and calibrate grinding machines according to specifications.

- Adjust grinding parameters, such as depth of cut and traverse speed.

2. Track Inspection

Inspect rail tracks before and after grinding to ensure that defects have been removed and the track is safe.

- Identify and mark defects on the rail surface.

- Measure the depth and width of defects.

3. Rail Grinding Maintenance

Maintain and repair track grinding equipment to ensure optimal performance and safety.

- Lubricate and adjust machine components.

- Change grinding wheels and other consumables.

4. Safety and Compliance

Follow all safety regulations and procedures when operating track grinding equipment and working on or near rail tracks.

- Wear appropriate protective gear, such as hard hats and safety glasses.

- Adhere to rail safety standards and guidelines.

Interview Tips

Preparing for a Track Grinder Operator interview requires showcasing your technical skills, problem-solving abilities, and commitment to safety.

1. Research the Company and Industry

Familiarize yourself with the rail industry, the company’s operations, and their approach to track maintenance.

- Visit the company website and read industry news.

- Network with professionals in the field.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating track grinding equipment, conducting track inspections, and maintaining rail systems.

- Quantify your accomplishments with specific examples.

- Use keywords from the job description to tailor your resume and cover letter.

3. Demonstrate Problem-Solving Abilities

Discuss situations where you identified and resolved track defects or equipment issues. Highlight your analytical thinking and decision-making skills.

- Share examples of how you solved complex problems effectively.

- Explain the steps you took to troubleshoot and resolve issues.

4. Emphasize Safety and Compliance

Stress your adherence to safety regulations and your understanding of rail safety standards.

- Describe your safety practices and how you ensure compliance in the workplace.

- Mention any safety certifications or training you have completed.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest and engagement. Prepare questions about the company’s track maintenance practices, safety protocols, and opportunities for professional development.

- Research the interviewer’s background and ask questions that align with their expertise.

- Be prepared to discuss your career goals and how they align with the company’s objectives.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Track Grinder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Track Grinder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.