Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Track Laminating Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Track Laminating Machine Tender so you can tailor your answers to impress potential employers.

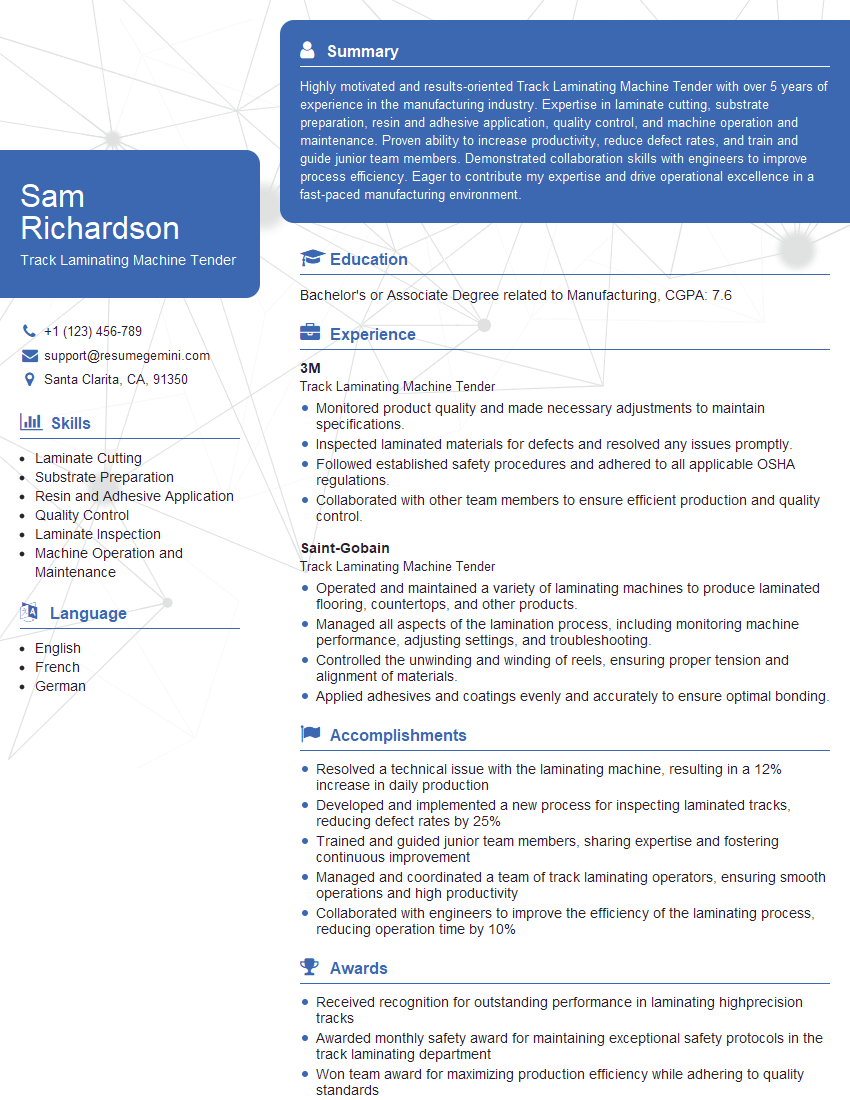

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Laminating Machine Tender

1. What are the key responsibilities of a Track Laminating Machine Tender?

The key responsibilities of a Track Laminating Machine Tender include:

- Operating and maintaining track laminating machines to produce laminated tracks

- Monitoring production processes and ensuring the quality of laminated tracks

- Troubleshooting and resolving machine malfunctions

- Performing preventive maintenance and repairs on machines

- Following safety protocols and maintaining a clean and organized work area

2. Describe the process of track laminating.

The process of track laminating involves adhering multiple layers of material together to create a durable and wear-resistant track. The steps typically include:

Pre-processing:

- Preparing the base material and adhesive

- Cleaning and applying primer to the surface

Lamination:

- Applying adhesive to the base material

- Layering the materials and pressing them together under heat and pressure

- Cooling and curing the laminated track

Post-processing:

- Trimming and shaping the track

- Conducting quality control inspections

3. What are the different types of track laminating machines?

There are various types of track laminating machines, each designed for specific applications. Common types include:

- Hydraulic presses: High-pressure machines used for large-scale production

- Pneumatic presses: Air-powered machines suitable for medium-sized tracks

- Roller presses: Machines with heated rollers for continuous lamination

- Vacuum presses: Machines that use vacuum to apply pressure for bonding materials

4. What are the factors that affect the quality of laminated tracks?

The quality of laminated tracks depends on several factors, including:

- Material selection: Compatibility and properties of the base material and adhesive

- Adhesive application: Uniformity and coverage of the adhesive layer

- Laminating parameters: Pressure, temperature, and dwell time during lamination

- Post-processing: Proper trimming, curing, and quality control measures

- Equipment maintenance: Regularly servicing and calibrating the laminating machine

5. What are some common problems encountered in track laminating operations?

Common problems that may occur in track laminating operations include:

- Adhesion failure: Poor bonding between materials due to improper surface preparation or adhesive selection

- Delamination: Separation of layers within the laminated track

- Wrinkles or bubbles: Trapped air or voids during lamination

- Edge defects: Chipping or fraying along the edges of the track

- Equipment malfunctions: Issues with the laminating machine, such as pressure or temperature variations

6. How do you ensure the safety of yourself and others while operating a track laminating machine?

Safety is paramount when operating a track laminating machine. I adhere to the following practices to ensure safety:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs

- Following proper operating procedures and lockout/tagout protocols

- Inspecting the machine regularly for any defects or potential hazards

- Maintaining a clean and organized work area, free from tripping hazards

- Reporting any safety issues or concerns to supervisors promptly

7. What are your strengths and weaknesses as a Track Laminating Machine Tender?

My strengths as a Track Laminating Machine Tender include:

- Strong technical knowledge of laminating processes and machinery

- Proven ability to operate and maintain track laminating machines

- Attention to detail and commitment to producing high-quality tracks

- Excellent problem-solving and troubleshooting skills

- Experience in implementing safety protocols and adhering to quality standards

As for weaknesses, I am always striving to improve my:

- Efficiency in laminating large batches

- Knowledge of advanced laminating techniques and equipment

- Leadership and supervisory skills for managing a team of operators

8. How do you stay updated with the latest advancements in track laminating technology?

To stay updated with the latest advancements in track laminating technology, I actively engage in the following practices:

- Attending industry conferences and trade shows

- Reading technical journals and white papers

- Participating in online forums and discussion groups

- Consulting with experts in the field and equipment manufacturers

- Seeking opportunities for professional development and training

9. What are your career aspirations as a Track Laminating Machine Tender?

As a Track Laminating Machine Tender, I aspire to:

- Continue developing my technical skills and knowledge in track laminating

- Advance to roles with greater responsibilities, such as supervisor or lead operator

- Contribute to process improvements and innovation in the field

- Share my expertise and train new operators

- Stay abreast of the latest industry trends and best practices

10. Why are you interested in working as a Track Laminating Machine Tender for our company?

I am drawn to your company because of its:

- Reputation as a leader in the industry

- Commitment to producing high-quality laminated tracks

- Focus on innovation and technology

- Investment in employee development and training

- Opportunities for career growth and advancement

I believe that my skills and experience would be a valuable asset to your team, and I am eager to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Laminating Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Laminating Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Track Laminating Machine Tenders are responsible for operating and maintaining track laminating machines, which are used to bond two or more layers of material together.

1. Operating Track Laminating Machines

The primary responsibility of a Track Laminating Machine Tender is to operate the laminating machine. This involves:

- Setting up the machine according to specifications

- Loading and unloading materials onto the machine

- Monitoring the machine during operation

- Adjusting the machine as needed to ensure proper operation

2. Maintaining Track Laminating Machines

In addition to operating the machine, Track Laminating Machine Tenders are also responsible for maintaining it. This involves:

- Performing routine maintenance tasks, such as cleaning and lubricating the machine

- Inspecting the machine for wear and tear

- Replacing worn or damaged parts

- Troubleshooting and repairing the machine as needed

3. Quality Control

Track Laminating Machine Tenders are also responsible for ensuring that the laminated materials meet quality standards. This involves:

- Inspecting the laminated materials for defects

- Rejecting any materials that do not meet standards

- Maintaining records of quality control checks

4. Safety

Track Laminating Machine Tenders must also follow all safety regulations and procedures. This involves:

- Wearing appropriate safety gear

- Operating the machine in a safe manner

- Reporting any unsafe conditions to a supervisor

Interview Tips

Preparing for an interview for a Track Laminating Machine Tender position can be daunting, but there are a few tips that can help you ace the interview.

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about your experience operating track laminating machines” and “What are your strengths and weaknesses?” Practice your answers to these questions beforehand so that you can deliver them confidently and concisely.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the job. For example, if you have experience operating a specific type of track laminating machine, be sure to mention that in your interview.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the job. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your ability to do the job.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the job and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Laminating Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!