Are you gearing up for an interview for a Transformer Shop Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Transformer Shop Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

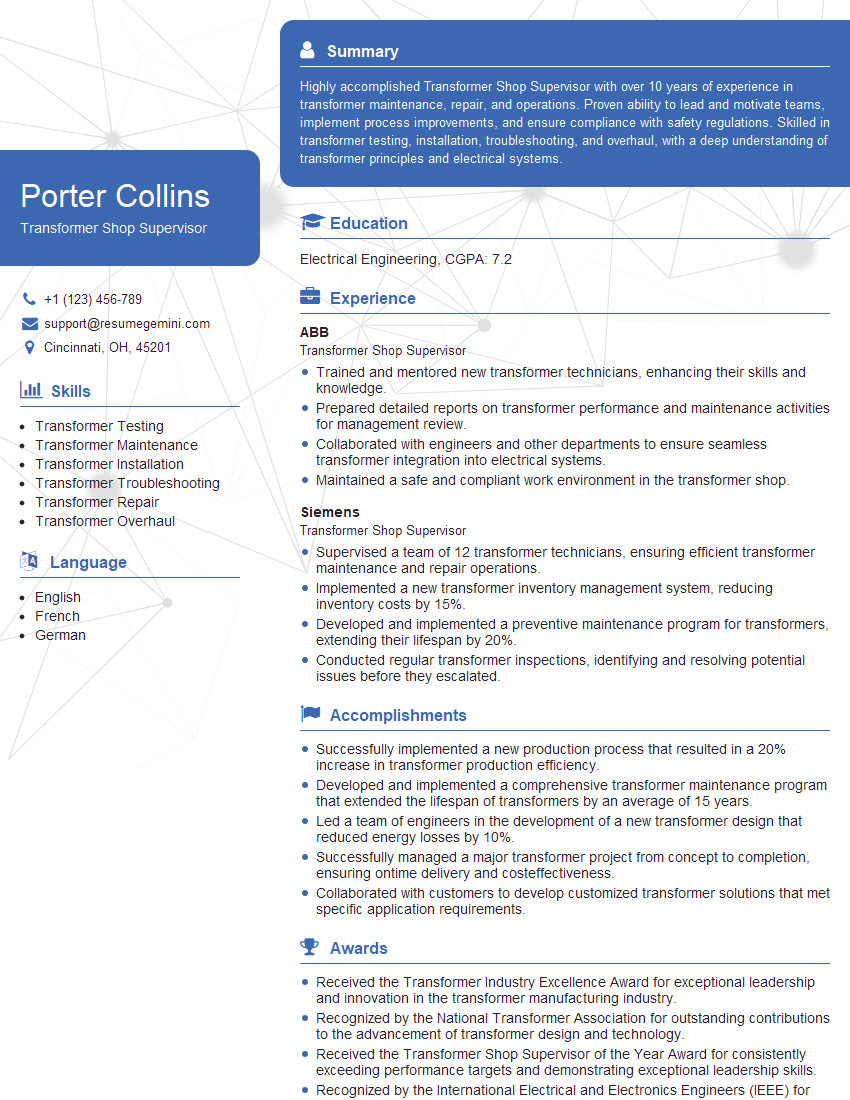

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Transformer Shop Supervisor

1. Explain the process of winding a transformer coil?

The process of winding a transformer coil involves several steps:

- Core preparation: The transformer core is prepared by stacking laminated steel sheets to create a magnetic circuit.

- Coil winding: The conductor material (typically copper or aluminum) is wound around the core in a specific pattern to create the primary and secondary coils.

- Insulation: Insulation is applied between the coils and between the coils and the core to prevent electrical shorts and ensure proper voltage isolation.

- Impregnation: The wound coils are impregnated with a varnish or resin to improve insulation and provide mechanical support.

- Drying and curing: The impregnated coils are dried and cured to remove moisture and solidify the insulation.

- Final assembly: The coils are assembled into the transformer housing, which includes the core, windings, and bushings.

2. Describe the different types of transformer cores and their applications?

Solid core transformers

- Made from a single piece of magnetic material

- Used in low-power transformers

- Provide good magnetic coupling, but can be bulky and heavy

Laminated core transformers

- Made from thin sheets of magnetic material stacked together

- Used in power transformers and distribution transformers

- Reduce eddy current losses compared to solid cores

Toroidal core transformers

- Have a toroidal shape with the windings wound around the circumference

- Provide high efficiency and low leakage inductance

- Used in high-frequency applications

3. Explain the purpose of tap-changers in transformers?

Tap-changers allow for the adjustment of the transformer’s turns ratio, which in turn changes the output voltage:

- On-load tap-changers (OLTCs): Allow for voltage adjustments while the transformer is in operation

- Off-load tap-changers: Require the transformer to be de-energized before making adjustments

- Tap-changers are used to compensate for voltage variations in the power grid or to provide voltage regulation in distribution systems

4. Discuss the factors that affect the efficiency of a transformer?

- Core losses: Energy lost due to hysteresis and eddy currents in the core

- Copper losses: Energy lost as heat in the windings due to resistance

- Stray losses: Energy lost due to leakage flux and other magnetic effects

- Load factor: The ratio of the average load to the transformer’s rated capacity

5. Describe the maintenance procedures for a transformer?

Regular maintenance is essential to ensure the safety and reliability of a transformer:

- Insulation testing: Periodic insulation testing to check for any degradation

- Oil testing: Testing of the transformer oil to monitor moisture, acidity, and dielectric strength

- Mechanical inspections: Checking for any loose connections, leaks, or corrosion

- Load monitoring: Monitoring the transformer’s load to ensure it does not exceed its rated capacity

- Preventive maintenance: Scheduled maintenance tasks to prevent future failures, such as cleaning, tightening connections, and replacing worn components

6. Explain the importance of cooling in transformers?

Cooling is crucial to prevent excessive temperatures in transformers:

- High temperatures can degrade insulation materials and reduce the transformer’s lifespan

- Cooling methods include natural air convection, forced air cooling, and liquid immersion

- Proper cooling ensures that the transformer operates at its rated temperature and avoids thermal overload

7. Discuss the role of bushings in transformers?

Bushings provide electrical insulation and mechanical support for the high-voltage terminals of transformers:

- Made from porcelain or composite materials

- Insulate the terminals from ground and prevent arcing

- Provide a weatherproof seal to protect against moisture and contaminants

8. Explain the principles of electromagnetic induction in transformers?

- When an alternating current flows through the primary coil, it creates a magnetic field

- This magnetic field links with the secondary coil, inducing an electromotive force (EMF) in the secondary

- The ratio of the primary to secondary turns determines the voltage ratio of the transformer

9. Describe the different types of faults that can occur in transformers?

- Winding faults: Short circuits or open circuits in the windings

- Core faults: Faults in the transformer core, such as shorts between laminations or ground faults

- Insulation faults: Breakdown of insulation between windings or between windings and ground

- Bushings faults: Insulation failures or mechanical damage to bushings

10. Explain the importance of safety procedures when working with transformers?

Transformers store large amounts of energy and can pose safety risks:

- Electrical hazards: High voltages and currents can cause electrical shock or arc flashes

- Mechanical hazards: Heavy components and moving parts can cause injuries

- Fire hazards: Transformer oil can be flammable

- Safety procedures include proper grounding, PPE, lockout/tagout, and regular inspections

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Transformer Shop Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Transformer Shop Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Transformer Shop Supervisor is responsible for overseeing the production of transformers in a manufacturing facility. The successful candidate will possess a thorough understanding of transformer manufacturing processes and the ability to lead a team of workers in a safe and efficient manner. Essential functions of this role include:

1. Production Management

The supervisor is responsible for planning, organizing, and directing the production of transformers. This includes:

- Developing and implementing production schedules

- Assigning tasks to workers

- Monitoring production progress

- Identifying and resolving production issues

2. Quality Control

The supervisor is responsible for ensuring that transformers are manufactured to meet quality standards. This includes:

- Inspecting transformers at various stages of production

- Identifying and correcting defects

- Maintaining quality control records

3. Safety Management

The supervisor is responsible for ensuring that the workplace is safe for workers. This includes:

- Developing and implementing safety procedures

- Training workers on safety procedures

- Enforcing safety regulations

4. Team Leadership

The supervisor is responsible for leading a team of workers. This includes:

- Motivating and inspiring workers

- Providing feedback and guidance to workers

- Resolving conflicts between workers

Interview Tips

To ace an interview for a Transformer Shop Supervisor position, it is important to prepare thoroughly and demonstrate your knowledge of the job and the industry. Here are some tips to help you prepare:

1. Research the Company and the Role

Before the interview, take some time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, social media pages, and Glassdoor.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this role?”. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and concisely. You can find a list of common interview questions online or in a book.

3. Highlight Your Relevant Experience and Skills

When you are answering interview questions, be sure to highlight your relevant experience and skills. For example, if you have experience in transformer manufacturing, be sure to mention this in your answer to the question “Tell me about your work experience”. You should also highlight any skills that are relevant to the role, such as leadership, problem-solving, and communication.

4. Be Enthusiastic and Positive

It is important to be enthusiastic and positive during your interview. This will show the interviewer that you are genuinely interested in the role and that you are confident in your abilities. Be sure to smile, make eye contact, and speak clearly and confidently.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the role and the company. This will show the interviewer that you are interested in the opportunity and that you are taking the interview seriously. You can ask questions about the company’s culture, the team you would be working with, and the company’s goals for the future.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Transformer Shop Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.