Are you gearing up for a career in Traverse Rod Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Traverse Rod Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

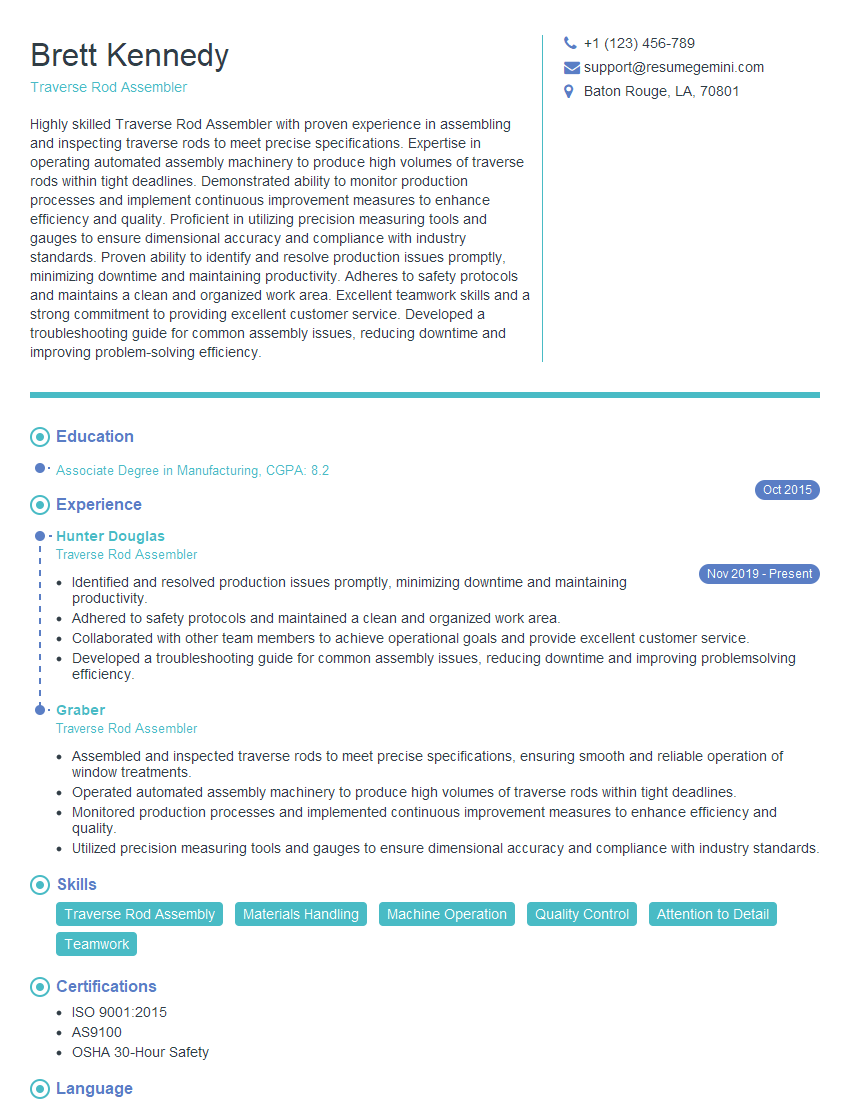

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Traverse Rod Assembler

1. How do you maintain the accuracy of the traverse rod assembly process?

To maintain the accuracy of the traverse rod assembly process, I follow a strict set of quality control procedures:

- Regularly calibrate all measuring and inspection equipment.

- Use precision measuring tools to ensure that the traverse rods are cut and assembled to the specified tolerances.

- Inspect the traverse rods at each stage of the assembly process to identify any defects or deviations from the specifications.

- Document all inspection results and take corrective actions to address any identified issues.

- Continuously monitor the assembly process to identify any areas for improvement and implement process enhancements.

2. What are the different types of traverse rod assemblies you have experience with? Describe their specific applications.

Linear Traverse Rod Assemblies:

- Used in linear actuators and motion control systems.

- Provide precise linear movement and positioning.

Rotary Traverse Rod Assemblies:

- Used in rotary actuators and indexing tables.

- Enable precise angular movement and positioning.

Telescopic Traverse Rod Assemblies:

- Used in applications requiring variable length adjustment.

- Provide extension and retraction capabilities with high stability and rigidity.

3. How do you ensure the proper alignment and fit of traverse rods in complex assemblies?

- Use precision alignment tools, such as laser alignment systems or dial indicators.

- Follow detailed assembly instructions and drawings to ensure proper orientation and positioning.

- Check for interference or binding during assembly to prevent damage or malfunction.

- Tighten all fasteners to the specified torque to maintain proper alignment and prevent loosening.

- Conduct thorough testing and inspection after assembly to verify alignment and fit.

4. What materials are commonly used in traverse rod assemblies, and how do their properties affect the assembly process?

- Steel: High strength and durability, but can be heavy and prone to corrosion.

- Aluminum: Lightweight and corrosion-resistant, but less strong than steel.

- Stainless Steel: Excellent corrosion resistance, but more expensive than other materials.

- Titanium: Strong and lightweight, but very expensive.

- Composite Materials: Offer a combination of strength, lightness, and corrosion resistance.

Understanding the properties of these materials helps me select the most suitable material for each assembly, considering factors such as strength, weight, durability, and cost.

5. How do you handle the assembly and installation of traverse rods in confined spaces or awkward positions?

In such situations, I employ the following techniques:

- Use specialized tools, such as flexible shafts or offset wrenches, to access hard-to-reach areas.

- Plan the assembly sequence carefully to minimize the need for working in confined spaces.

- Consider using pre-assembled components or subassemblies to reduce the complexity of the installation.

- Maximize the use of ergonomic techniques to prevent discomfort or injuries.

6. What troubleshooting techniques do you use to identify and resolve issues in traverse rod assemblies?

- Visual Inspection: Examine the assembly for any visible defects, misalignments, or loose connections.

- Dimensional Measurement: Use precision measuring tools to verify the dimensions and tolerances of the assembly.

- Performance Testing: Conduct functional tests to assess the movement, accuracy, and stability of the assembly.

- Analysis of Data: Review inspection and test results to identify potential causes of issues.

- Root Cause Analysis: Determine the underlying reasons for the problems and develop corrective actions to prevent recurrence.

7. What safety precautions do you observe when working with traverse rod assemblies?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and ear protection.

- Ensure that the assembly is properly supported and stable before handling or adjusting.

- Never work on energized systems.

- Follow lockout/tagout procedures to prevent accidental operation.

- Be aware of potential pinch points or sharp edges during assembly and disassembly.

8. How do you stay up-to-date with the latest advancements and best practices in traverse rod assembly techniques?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with experts and manufacturers.

- Participate in online forums and discussion groups.

- Seek opportunities for training and professional development.

9. What quality assurance measures do you implement to ensure the reliability and performance of traverse rod assemblies?

- Comply with industry standards and regulations.

- Conduct thorough inspections and tests at each stage of the assembly process.

- Document all assembly procedures and inspection results.

- Establish traceability systems to track components and materials.

- Implement continuous improvement initiatives to identify and eliminate potential quality issues.

10. Can you describe a situation where you had to overcome a challenge or implement an innovative solution in traverse rod assembly?

Provide a specific example of a challenging assembly task, how you approached the problem, and the innovative solution you implemented to achieve the desired outcome. Explain the impact of your solution and how it improved the assembly process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Traverse Rod Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Traverse Rod Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Traverse Rod Assembler is responsible for creating and inspecting traverse rods used for curtains and other window treatmentsThe job responsibilities of a Traverse Rod Assembler typically include:

1. Gathering Materials

The assembler gathers the raw materials needed to create the traverse rods, including metal tubes, brackets, and end caps

- Ensuring that the materials meet the required specifications

- Inspecting the materials for any defects or damage

2. Cutting and Shaping Materials

The assembler cuts the metal tubes to the desired length and shapes the brackets and end caps using specialized equipment

- Using precision tools and machinery to ensure accurate cuts and shapes

- Following established quality standards and specifications

3. Assembling Traverse Rods

The assembler assembles the traverse rods by attaching the brackets to the metal tubes and securing the end caps

- Using appropriate tools and techniques to ensure a sturdy and durable assembly

- Inspecting the assembled traverse rods for any imperfections or defects

4. Testing and Packaging

The assembler tests the traverse rods to ensure they operate smoothly and meet the required specifications

- Conducting operational tests to check the movement and functionality of the traverse rods

- Packaging the assembled traverse rods for shipment or storage

Interview Tips

To prepare for an interview for a Traverse Rod Assembler position, candidates should consider the following tips:

1. Research the Company and Position

Before the interview, candidates should research the company and the specific position they are applying for

- Visiting the company’s website and social media pages

- Reviewing the job description thoroughly to understand the key responsibilities and requirements

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that are most relevant to the Traverse Rod Assembler position

- Quantifying accomplishments and providing specific examples of their work

- Highlighting their attention to detail, precision, and ability to meet deadlines

3. Demonstrate Understanding of the Industry

Candidates should demonstrate their understanding of the window treatment industry and the products they produce

- Being familiar with different types of traverse rods and their applications

- Understanding the latest trends and innovations in the industry

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows that candidates are engaged and interested in the position

- Preparing questions that demonstrate their knowledge and enthusiasm for the role

- Asking about the company’s culture, growth opportunities, and commitment to quality

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Traverse Rod Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!