Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trench Pipe Layer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

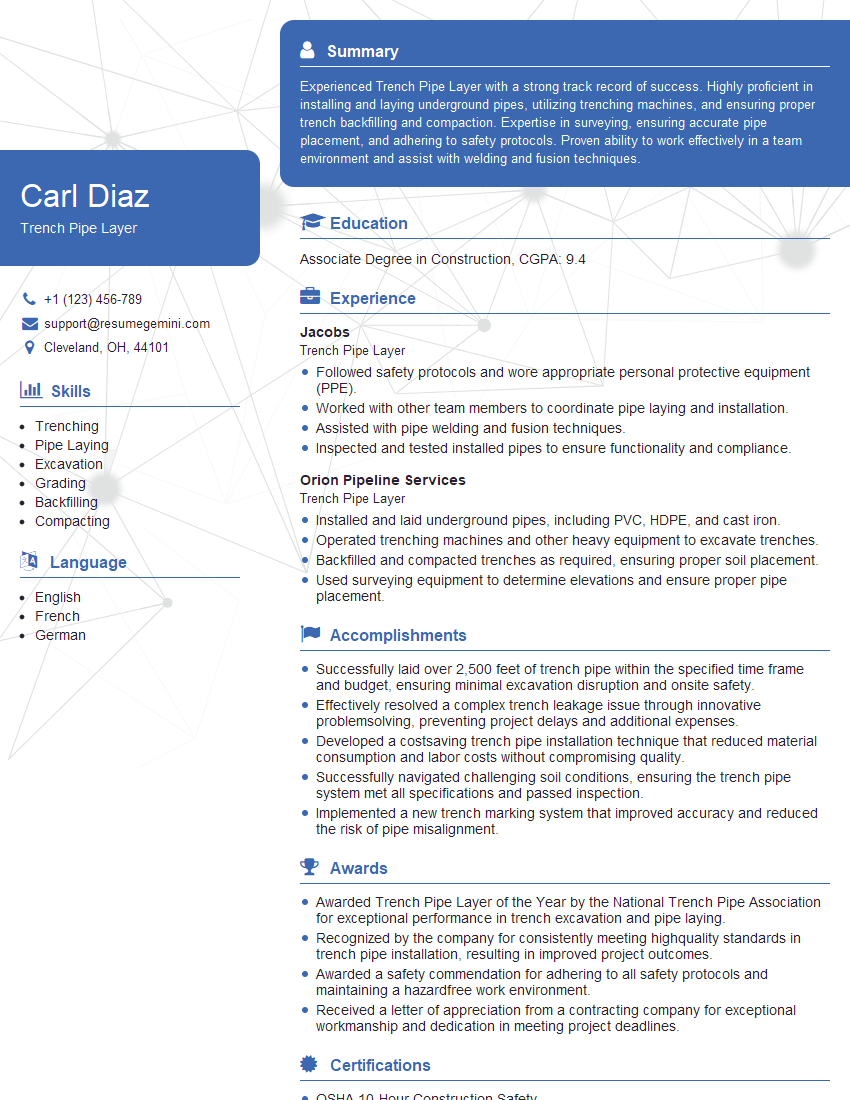

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trench Pipe Layer

1. Describe the steps involved in trench preparation and excavation for pipe laying.

- Mark out the trench location according to the project plan.

- Remove any obstacles or vegetation from the trench area.

- Excavate the trench using the appropriate equipment, such as a trencher or excavator.

- Ensure the trench is stable and has the correct depth, width, and slope.

- Inspect the trench for any hazards or defects before pipe laying.

2. What factors determine the type of bedding material used in a trench?

Soil Conditions

- Soil bearing capacity

- Soil particle size and texture

- Soil moisture content

Pipe Requirements

- Pipe diameter

- Pipe material

- Pipe stiffness

Project Specifications

- Design code requirements

- Project-specific guidelines

3. How do you ensure proper handling and storage of pipes before laying?

- Inspect pipes for any damage or defects upon arrival.

- Store pipes on stable and level ground, elevated if necessary.

- Protect pipes from weather conditions using tarps or covers.

- Use slings or hoists to lift and move pipes safely.

- Follow manufacturer’s instructions for proper handling and storage.

4. What techniques are used to join pipes in a trench?

- Solvent Welding: Joining plastic pipes using chemicals that melt and fuse the pipe ends.

- Heat Fusion: Using heat to melt and join the ends of plastic pipes.

- Mechanical Joints: Using gaskets, clamps, or bolts to connect pipes without welding.

- Flanged Joints: Bolting together pipe sections that have flanges welded to their ends.

5. How do you test the integrity and functionality of a newly laid pipeline?

- Hydrostatic Testing: Filling the pipeline with water and pressurizing it to test for leaks.

- Pneumatic Testing: Filling the pipeline with air or gas and pressurizing it to test for leaks.

- Non-Destructive Testing: Using methods like ultrasonic testing or radiography to detect defects in the pipes.

- Visual Inspection: Inspecting the pipeline for any visible leaks, damage, or misalignment.

6. What safety measures are essential when working on a trench pipe laying project?

- Wear appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Use trench boxes or shoring to prevent trench collapses.

- Be aware of overhead hazards, such as power lines or trees.

- Follow safe lifting and excavation practices.

- Have a plan for emergency situations, including communication and evacuation procedures.

7. How do you determine the slope and depth of a trench based on the project requirements?

- Refer to project specifications and design plans.

- Consider the type of pipe being installed and its required cover.

- Account for soil conditions and drainage requirements.

- Use surveying equipment or laser levels to establish the trench slope and depth.

- Adjust the slope and depth as needed to ensure proper pipe performance and prevent damage.

8. What is the purpose of backfilling and compaction after pipe laying?

- Restore the surface to its original condition.

- Provide support and stability to the pipeline.

- Prevent erosion and settling.

- Protect the pipeline from external damage.

- Ensure the pipeline operates properly under various conditions.

9. Describe the different types of backfill materials used in trench pipe laying and their advantages.

- Native Soil: Readily available and cost-effective, but requires proper compaction.

- Sand: Provides good drainage and easy compaction, but can be expensive.

- Gravel: Ensures high load-bearing capacity and drainage, but may be less cost-effective.

- Flowable Fill: Self-leveling and easy to work with, but can be more expensive.

- Mechanically Stabilized Earth (MSE): A mixture of soil and reinforcement materials, providing high strength and stability.

10. What are the common challenges faced by Trench Pipe Layers and how do you overcome them?

- Trench Stability: Use trench boxes, shoring, or sloping to prevent cave-ins.

- Water: Use pumps to dewater the trench or install drainage systems.

- Underground Utilities: Identify and protect existing utilities using potholing or hand excavation.

- Soil Conditions: Adapt excavation methods and backfill materials based on soil type and moisture content.

- Extreme Weather: Monitor weather forecasts and take precautions to protect the pipeline and workers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trench Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trench Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trench Pipe Layers are vital to the construction industry, ensuring the safe and efficient installation of pipes below ground. Their responsibilities entail a wide range of tasks, including:

1. Trench Excavation

Utilizing digging equipment, Trench Pipe Layers excavate trenches to the specified depth and width, ensuring they meet project requirements and safety standards.

- Operate excavators, backhoes, and other heavy machinery.

- Ensure trenches are excavated to the correct dimensions and alignment.

2. Pipe Installation

After trench excavation, Trench Pipe Layers carefully place pipes into the trenches, ensuring proper alignment and connection.

- Handle and transport pipes of various sizes and materials.

- Connect pipes using fittings, gaskets, and sealants.

3. Backfilling and Compaction

Once pipes are installed, Trench Pipe Layers fill the trenches with excavated soil or other materials, ensuring the pipes are secure and protected.

- Backfill trenches using excavators, compactors, and other equipment.

- Compact the backfill material to prevent settling and ensure proper support for the pipes.

4. Safety Compliance

Trench Pipe Layers prioritize safety throughout their work, adhering to established protocols and regulations.

- Wear appropriate safety gear, including hard hats, safety glasses, and gloves.

- Identify and mitigate potential hazards, such as collapsed trenches or underground utilities.

Interview Tips

To enhance your chances of success in the interview for a Trench Pipe Layer position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company you’re applying to, their projects, and the construction industry in general. This knowledge demonstrates your interest and enthusiasm.

- Visit the company’s website and read industry publications.

- Connect with individuals working in the field to gain insights.

2. Emphasize Relevant Skills and Experience

Highlight your proficiency in trench excavation, pipe installation, and safety protocols. Provide specific examples from your previous experience to illustrate your abilities.

- Quantify your accomplishments whenever possible, using metrics or data.

- Be prepared to discuss any challenges you’ve faced and how you overcame them.

3. Demonstrate Physical Strength and Endurance

Trench Pipe Laying is physically demanding. Prepare to emphasize your physical strength and endurance. Discuss your experience working in strenuous conditions.

- Mention any relevant certifications or training you have in heavy machinery operation.

- Share examples of your physical fitness and stamina.

4. Show Enthusiasm and Teamwork

Convey your passion for the construction industry and your ability to work effectively as part of a team. Discuss your commitment to safety and your willingness to collaborate.

- Describe your experiences working with diverse teams and contributing to successful projects.

- Express your interest in learning from experienced colleagues and contributing to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trench Pipe Layer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!