Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tricot Knitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

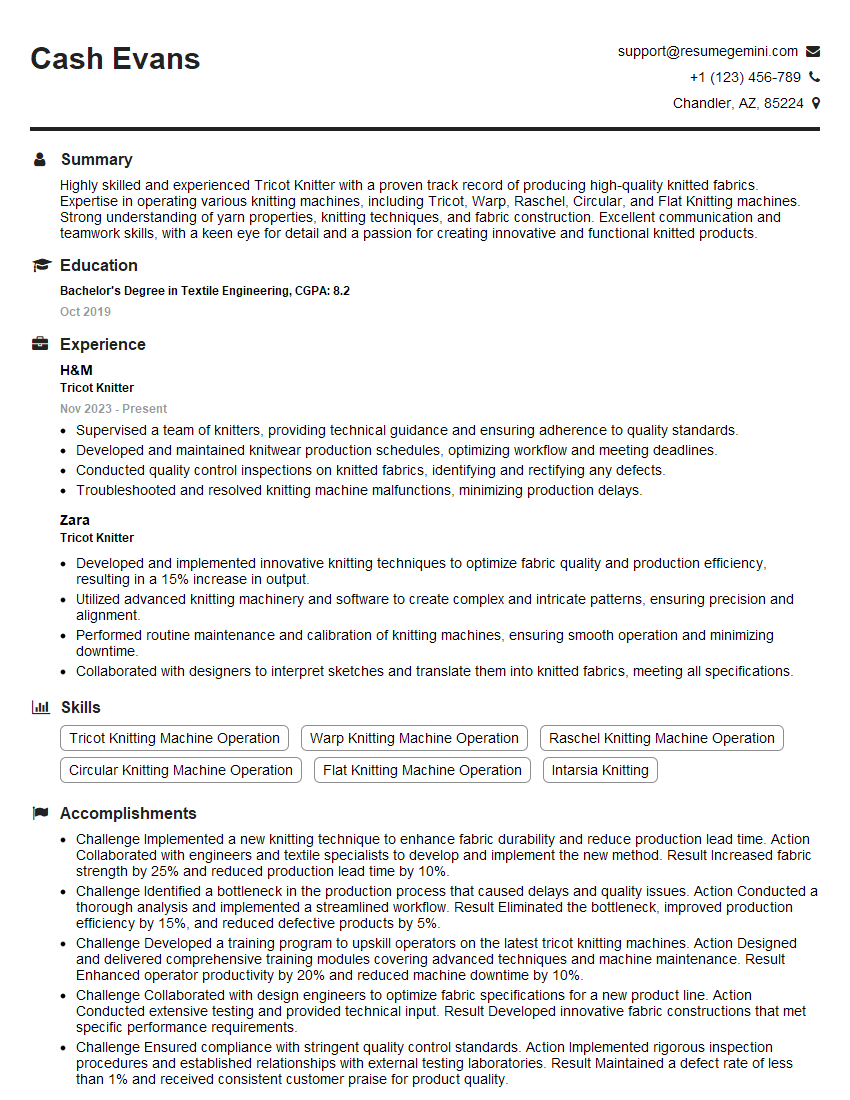

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tricot Knitter

1. Describe the process of preparing a tricot knitting machine for operation.

- Check the machine for any damage or loose parts.

- Clean the machine and remove any dust or debris.

- Install the yarn and set the tension.

- Adjust the stitch length and width.

- Set the machine to the desired stitch pattern.

2. How do you troubleshoot a tricot knitting machine that is not producing fabric properly?

Checking the yarn tension

- If the yarn tension is too tight, the fabric will be too dense and may not stretch properly.

- If the yarn tension is too loose, the fabric will be too loose and may run or ladder.

Checking the stitch length and width

- If the stitch length is too short, the fabric will be too dense and may not stretch properly.

- If the stitch length is too long, the fabric will be too loose and may run or ladder.

- If the stitch width is too narrow, the fabric will be too dense and may not stretch properly.

- If the stitch width is too wide, the fabric will be too loose and may run or ladder.

Checking the stitch pattern

- If the stitch pattern is not set correctly, the fabric will not be produced correctly.

3. What are the different types of tricot knitting machines?

- Single-needle tricot machines

- Double-needle tricot machines

- Multi-needle tricot machines

- High-speed tricot machines

- Electronic tricot machines

4. What are the advantages and disadvantages of using a tricot knitting machine?

Advantages

- Tricot knitting machines are very efficient and can produce fabric quickly.

- Tricot knitting machines can produce a wide variety of fabrics, from lightweight sheer fabrics to heavy upholstery fabrics.

- Tricot knitting machines are relatively easy to operate.

Disadvantages

- Tricot knitting machines can be expensive to purchase and maintain.

- Tricot knitting machines can be noisy.

- Tricot knitting machines can produce fabric that is not as durable as fabric produced by other knitting methods.

5. How do you care for a tricot knitting machine?

- Clean the machine regularly to remove any dust or debris.

- Oil the machine regularly to keep it running smoothly.

- Inspect the machine regularly for any damage or loose parts.

- Store the machine in a dry, climate-controlled environment.

6. What are the safety precautions that must be taken when operating a tricot knitting machine?

- Never operate a tricot knitting machine without proper training.

- Always wear safety glasses when operating a tricot knitting machine.

- Never reach into a tricot knitting machine while it is running.

- Never operate a tricot knitting machine with loose clothing or jewelry.

- Keep the work area around a tricot knitting machine clean and free of debris.

7. What are the different types of fabrics that can be produced on a tricot knitting machine?

- Lace

- Netting

- Velour

- Satin

- Ribbing

8. What are the factors that affect the quality of fabric produced on a tricot knitting machine?

- The type of yarn used

- The tension of the yarn

- The stitch length

- The stitch width

- The stitch pattern

- The machine speed

9. What are the applications of fabrics produced on a tricot knitting machine?

- Clothing

- Home furnishings

- Industrial fabrics

10. What is the future of tricot knitting technology?

- The development of new and innovative stitch patterns

- The use of new materials, such as recycled fibers and biodegradable fibers

- The development of more efficient and automated tricot knitting machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tricot Knitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tricot Knitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tricot Knitter plays a significant role in the textile industry, specializing in the production of fabrics using a tricot knitting machine. The individual is responsible for ensuring the smooth functioning of the machine, maintaining the quality of the fabrics produced, and meeting production targets. Here are key job responsibilities of a Tricot Knitter:

1. Operate and Maintain Equipment

Tricot Knitters operate and maintain tricot knitting machines, ensuring they run smoothly and efficiently. They conduct regular inspections, clean and lubricate the machines, and make necessary adjustments to optimize performance.

2. Fabric Production and Quality Control

They are responsible for producing high-quality fabrics that meet specified requirements. They monitor the knitting process, check fabric quality, and make adjustments to yarn tension, machine settings, and other parameters to achieve the desired results.

3. Machine Troubleshooting and Repairs

Tricot Knitters troubleshoot and resolve machine malfunctions promptly. They identify the cause of problems, perform repairs, and ensure the machine is back in operation as soon as possible to minimize production downtime.

4. Production and Efficiency Optimization

To ensure efficiency and meet production targets, they analyze and identify areas for improvement. They work with other team members to implement changes that optimize production processes and increase machine uptime.

Interview Tips

Preparing for a job interview can be daunting, but with the right tips and strategies, you can increase your chances of success. Here are key tips to help you ace your Tricot Knitter interview:

1. Research the Company and Position

Take the time to research the company and the specific Tricot Knitter position you’re applying for. Familiarize yourself with their products, services, industry standing, and company culture. This will help you understand the organization and its needs, and show the interviewer that you’re genuinely interested in the role.

2. Practice Common Interview Questions

Practice answering common interview questions related to the Tricot Knitter role. Anticipate questions about your experience operating and maintaining tricot knitting machines, fabric production techniques, quality control measures, and problem-solving abilities. Prepare clear and concise responses that highlight your skills and qualifications.

3. Highlight Your Relevant Skills and Experience

Emphasize your relevant skills and experience in the interview. Quantify your accomplishments whenever possible, using specific examples to demonstrate your capabilities as a Tricot Knitter. For instance, describe how you improved production efficiency by implementing a new technique or reduced machine downtime through effective troubleshooting.

4. Demonstrate Your Technical Knowledge

Showcase your technical knowledge of tricot knitting machines. Discuss your understanding of different machine components, knitting techniques, and fabric properties. Explain how you use this knowledge to optimize production and ensure fabric quality.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare questions about the company’s production processes, quality standards, or future plans. This shows the interviewer that you’re eager to learn more and are genuinely interested in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tricot Knitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tricot Knitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.