Are you gearing up for a career in Trim Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Trim Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

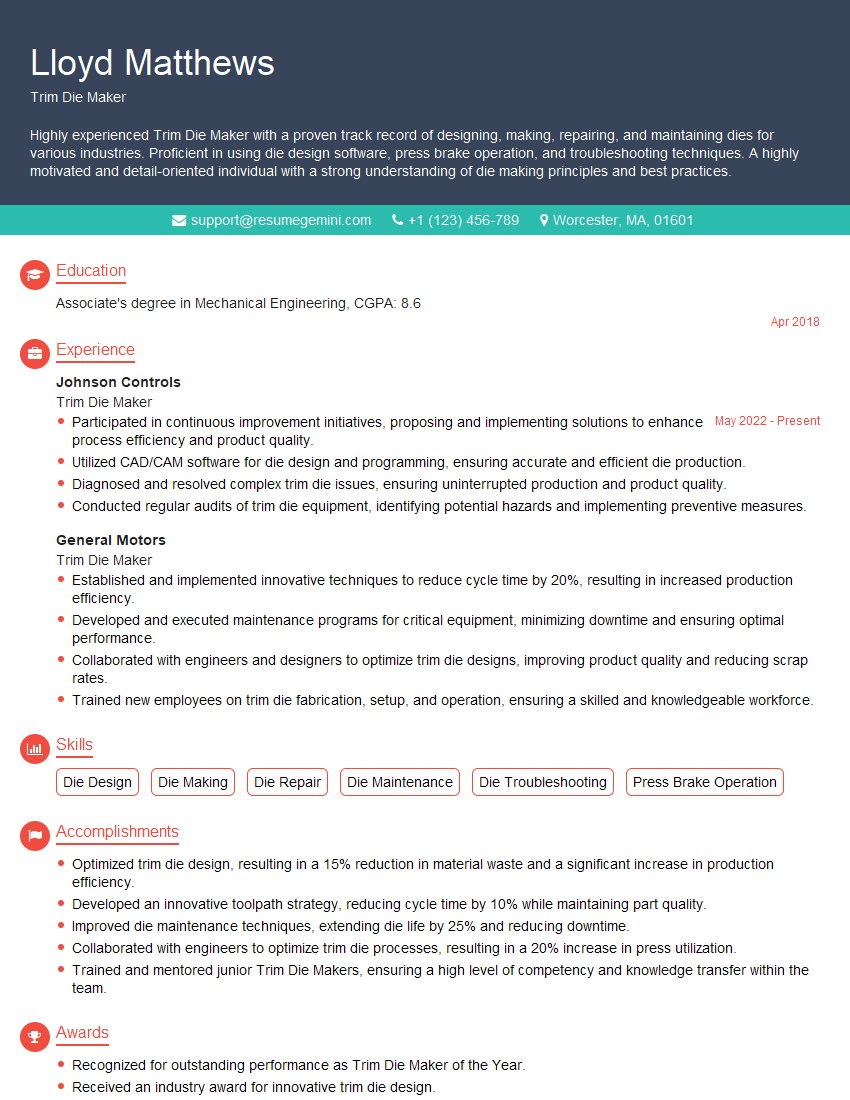

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trim Die Maker

1. What is the difference between a blanking die and a trimming die?

- Blanking die cuts the part completely out of the material

- Trimming die removes the excess material from around the edge of a part

2. What are the different types of trimming dies?

Progressive Trimming Die

- Used to trim multiple features in a single operation

- Stripping fingers automatically remove the trimmed material

Compound Trimming Die

- Similar to progressive trimming die, but has multiple stations for different trimming operations

- Strippers are mounted on the outer component of the die

Single Operation Trimming Die

- Used for simple trimming operations

- Manually operated, with the stripper plate removed after each trim

3. What are the key considerations when designing a trim die?

- Part geometry and its function

- Material properties and thickness

- Required trim tolerance and quality

- Automation requirements and production volume

- Machine capabilities and limitations

4. How do you determine the proper clearance between the punch and die?

- Based on the material thickness and properties

- Too little clearance can cause excessive wear or breakage

- Too much clearance can result in poor trim quality and burrs

- Use formulas or guidelines based on material type and thickness

5. What are the common problems encountered in trimming operations and how do you resolve them?

- Tearing: Adjust punch and die clearance, increase holddown pressure

- Burring: Check for proper clearance, improve punch sharpness, apply anti-burr lubricants

- Die wear: Use hardened tool steel, proper lubrication, reduce cutting forces

- Part distortion: Increase holddown pressure, adjust die alignment, consider using clamps

- Breakage: Check for proper heat treatment, reduce cutting forces, use stronger materials

6. How do you maintain and inspect trim dies?

- Regular cleaning and lubrication

- Checking for wear and damage

- Sharpening punches and replacing worn components

- Inspecting for proper alignment and clearance

7. What are the safety precautions to observe when working with trim dies?

- Wear appropriate PPE (eye protection, gloves, etc.)

- Follow lockout/tagout procedures

- Keep hands away from moving parts

- Handle and store dies properly to prevent accidents

8. What software do you use for trim die design and analysis?

- CAD software for 3D modeling

- Simulation software for FEA and stress analysis

- CAM software for generating NC code

9. What are the latest trends and advancements in trim die technology?

- Use of carbide inserts for improved wear resistance

- Laser trimming for precise and complex cuts

- Integration of sensors for monitoring and control

- Automation and robotics for increased efficiency

10. How do you stay updated on the latest developments in the field of trim die making?

- Attend industry trade shows and conferences

- Read technical publications and articles

- Participate in online forums and discussions

- Collaborate with experts and colleagues

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trim Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trim Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Trim Die Maker

Trim Die Makers are responsible for designing, constructing, and maintaining trim dies used in stamping and forming operations. They play a crucial role in the production process, ensuring the accuracy and precision of metal parts manufactured using these dies.

1. Die Design and Development

Trim Die Makers collaborate with engineers and designers to conceptualize and develop new trim dies. Using computer-aided design (CAD) software, they create 3D models of the dies, taking into account material properties, part geometry, and manufacturing constraints.

- Design dies for blanking, piercing, forming, and other stamping operations.

- Analyze part blueprints, specifications, and material properties to determine optimal die design.

2. Die Construction and Assembly

Trim Die Makers oversee the construction and assembly of trim dies in fabrication shops. They use precision machining equipment, such as CNC mills and lathes, to manufacture individual die components, including punches, dies, retainers, and stripper plates.

- Fabricate and assemble die components using various machining techniques.

- Ensure proper fit and alignment of die components during assembly.

3. Die Maintenance and Repair

Trim Die Makers are responsible for maintaining and repairing trim dies throughout their service life. They perform regular inspections to identify potential issues, such as wear and tear, misalignment, or damage. They also conduct preventive maintenance to minimize downtime and ensure optimal die performance.

- Inspect and diagnose die malfunctions and identify root causes.

- Perform die repairs, replacements, and adjustments as needed.

4. Quality Control and Testing

Trim Die Makers play a vital role in ensuring the quality of parts produced using trim dies. They conduct sample testing to verify die performance and part accuracy. They also work closely with quality control personnel to identify and correct any deviations from specifications.

- Conduct sample part inspections to assess die performance.

- Monitor production processes and make adjustments to dies as needed to maintain quality standards.

Interview Tips for Trim Die Makers

Preparing thoroughly for an interview can significantly increase your chances of impressing the hiring manager and landing the job. Here are some essential interview tips for Trim Die Makers:

1. Research the Company and Position

Take the time to thoroughly research the company you are applying to, including its products, services, history, and current projects. This will demonstrate your interest in the position and the company itself. Familiarize yourself with the specific job responsibilities and qualifications required for the role.

- Visit the company’s website and social media pages to gather information.

- Read industry news and articles to gain insights into the company’s market position.

2. Practice Your Answers to Common Interview Questions

Anticipate and prepare for common interview questions, such as those related to your experience, skills, and qualifications. Practice your answers in advance to ensure clarity, conciseness, and relevance to the position you are applying for. Consider using the STAR method when answering behavioral questions:

- Situation: Describe the specific situation or task you were involved in.

- Task: Explain the task or responsibility you had to complete.

- Action: Detail the specific actions you took to complete the task.

- Result: Describe the achieved outcome or result of your actions.

3. Showcase Your Technical Skills and Experience

Highlight your technical skills and experience as a Trim Die Maker. Quantify your accomplishments whenever possible to provide tangible evidence of your contributions. Use specific examples to demonstrate your expertise in die design, construction, maintenance, and quality control.

- Describe successful projects where you played a key role in designing and developing trim dies.

- Explain how you have used your skills to improve die efficiency and reduce downtime.

4. Emphasize Your Problem-Solving Abilities

As a Trim Die Maker, you will often encounter challenges and unexpected situations. Highlight your problem-solving abilities by providing examples of how you have successfully identified, analyzed, and resolved die-related issues.

- Share an experience where you diagnosed a die malfunction and implemented a solution to minimize production downtime.

- Describe a project where you redesigned a die to improve part quality or increase production efficiency.

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, and the industry. This shows that you are engaged and genuinely interested in the opportunity. Asking informed questions also allows you to clarify any doubts and gain additional insights into the company culture and work environment.

- Inquire about the company’s growth plans and strategies for the future.

- Ask about the company’s commitment to training and professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Trim Die Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.