Feeling lost in a sea of interview questions? Landed that dream interview for Trimmer and Borer Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Trimmer and Borer Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

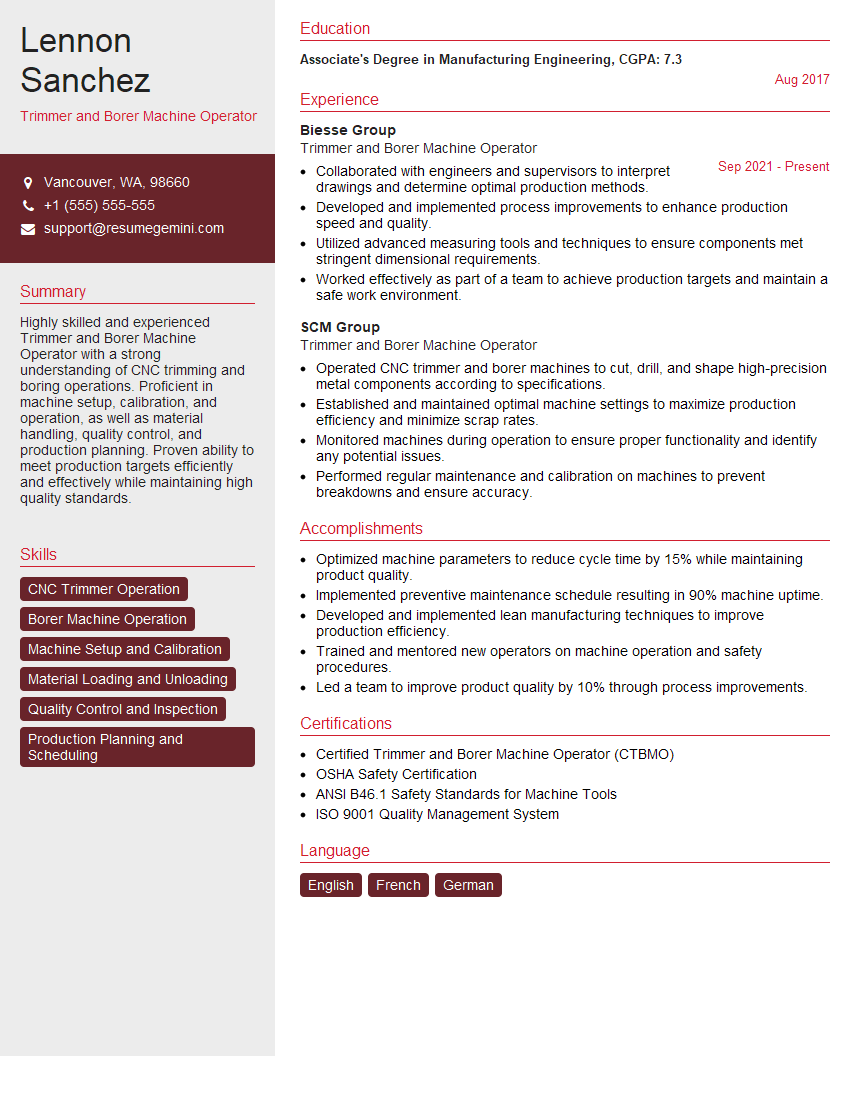

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimmer and Borer Machine Operator

1. Explain the different types of trimmers and borers used in woodwork?

- Fixed-base trimmer: Used for cutting straight and curved edges, grooving, and template routing.

- Plunge router: Used for cutting mortises, slots, and decorative inlays, and for routing the edges of curved workpieces.

- Horizontal boring machine: Used for drilling horizontal holes for dowels, pegs, or other hardware.

2. What are the key safety considerations when operating a trimmer or borer machine?

PPE

- Wear eye protection, ear protection, and a dust mask to protect against flying wood chips and dust.

- Wear snug-fitting clothing to avoid entanglement.

Machine Operation

- Ensure the machine is properly grounded.

- Securely clamp the workpiece to prevent movement.

- Use sharp bits and cutters to reduce the risk of kickback.

- Never operate the machine while under the influence of drugs or alcohol.

3. Describe the process of setting up and operating a trimmer machine.

- Choose the appropriate bit or cutter for the task.

- Adjust the depth of cut and fence position.

- Secure the workpiece and position the trimmer.

- Turn on the machine and carefully guide it along the desired path.

- Use a featherboard or push block to provide support and prevent kickback.

4. What are the common problems that can occur when using a borer machine and how do you troubleshoot them?

Problem 1: Bit breaks frequently

- Possible cause: Dull or damaged bit

- Solution: Replace or sharpen the bit

Problem 2: Hole is not straight

- Possible cause: Workpiece not securely clamped

- Solution: Secure the workpiece properly

5. How do you handle different types of wood when working with a trimmer or borer machine?

Hardwoods: Use sharp bits, slow feed rates, and reduce the depth of cut.

Softwoods: Use higher feed rates and deeper cuts, but be cautious of tear-out.

Plywood: Use smaller bits and take shallow passes to avoid delamination.

MDF: Use carbide-tipped bits and adjust the feed rate and depth of cut to prevent burning.

6. What are the advantages and disadvantages of using a trimmer over a router table?

Advantages of trimmer:

- Portability and ease of use

- Can be used for freehand routing

Disadvantages of trimmer:

- Less precision and accuracy

- Limited range of operations

7. How do you maintain and care for trimmer and borer machines to ensure optimal performance?

- Keep machines clean and free of dust and debris.

- Lubricate moving parts regularly.

- Inspect bits and cutters for wear and damage.

- Store machines in a clean and dry place.

8. What are your troubleshooting tips for common problems that arise when operating a boring machine?

Problem: Bit gets stuck in the workpiece

- Possible cause: Dull or damaged bit

- Solution: Replace or sharpen the bit

Problem: Hole is not round

- Possible cause: Misaligned bit

- Solution: Adjust the bit alignment

9. How do you ensure the accuracy and precision of your work when operating a trimmer or borer machine?

- Use jigs and templates to guide the machine.

- Secure the workpiece firmly to prevent movement.

- Make multiple passes with shallow depth of cuts to achieve greater accuracy.

- Check the accuracy of your cuts regularly using measuring tools.

10. Describe a challenging project you have worked on involving the use of a trimmer or borer machine and how you overcame the challenges.

Describe the project, the challenges you faced, and how you used your skills and knowledge to overcome them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimmer and Borer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimmer and Borer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trimmer and Borer Machine Operators are responsible for operating and maintaining Trimmer and Borer machines for accurate trimming, boring, and shaping various materials.

1. Machine Operation

intro paragraph

- Loading and unloading workpieces on the machines.

- Setting up and operating Trimmer and Borer machines according to specifications.

2. Quality Control

intro paragraph

- Inspecting and measuring workpieces to ensure accuracy and conformance.

- Adjusting machines and processes to meet required tolerances.

3. Maintenance and Troubleshooting

intro paragraph

- Performing minor maintenance tasks and repairs on machines.

- Identifying and resolving operational issues and machine malfunctions.

4. Safety Compliance

intro paragraph

- Adhering to established safety protocols and regulations.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some tips to help you ace your Trimmer and Borer Machine Operator interview:

1. Research the Company and Position

Researching the company and the specific position you’re applying for shows the interviewer that you’re genuinely interested in the opportunity. Look into the company’s website, LinkedIn page, and industry news to learn about their culture, values, and recent developments. Understanding the specific responsibilities and requirements of the Trimmer and Borer Machine Operator role will help you tailor your answers to the interviewer’s questions.

2. Practice Answering Common Interview Questions

Take some time to practice answering common interview questions, especially those related to your skills and experience as a Trimmer and Borer Machine Operator. You can use the key job responsibilities listed above to guide your preparation. Prepare specific examples from your past work experience that demonstrate your abilities in machine operation, quality control, maintenance, and safety compliance.

3. Highlight Your Technical Skills and Experience

The interviewer will want to know about your technical skills and experience in operating Trimmer and Borer machines. Clearly articulate your proficiency in loading and unloading workpieces, setting up and operating machines, and performing inspections and measurements. If you have experience with specific types of Trimmer and Borer machines, mention those by name and explain how you used them effectively.

4. Emphasize Your Attention to Detail and Precision

Trimmer and Borer Machine Operators must have a keen eye for detail and a commitment to precision. In your interview, emphasize your ability to inspect and measure workpieces accurately and make necessary adjustments to ensure conformance to specifications. Share examples of when you identified and corrected errors or implemented improvements to enhance the accuracy of your work.

5. Showcase Your Problem-Solving Abilities

Unexpected issues and machine malfunctions are common in manufacturing environments. The interviewer will want to know how you handle these situations. Highlight your problem-solving skills by providing examples of times when you identified and resolved operational issues or machine malfunctions. Explain the steps you took to diagnose the problem, develop a solution, and implement it effectively.

6. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show the interviewer that you are passionate about working as a Trimmer and Borer Machine Operator and that you are eager to contribute to the company’s success. Be polite, respectful, and professional in your interactions with the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trimmer and Borer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!