Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trimmer Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

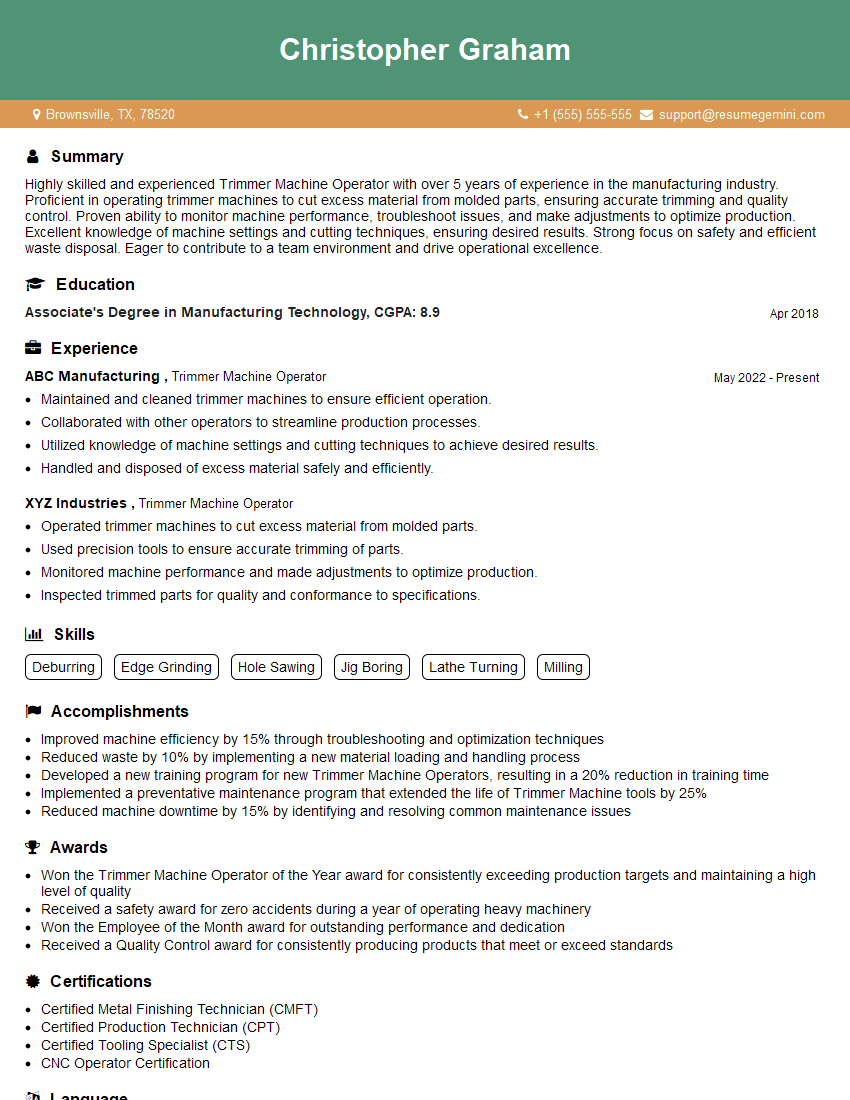

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimmer Machine Operator

1. Explain the process of trimming different types of fabrics?

- Start by identifying the type of fabric and its properties.

- Select the appropriate blade and settings on the trimmer machine.

- Ensure the fabric is aligned properly and feed it through the machine evenly.

- Monitor the trimming process and make necessary adjustments to maintain accuracy.

- Inspect the trimmed fabric to ensure it meets quality standards.

2. How do you maintain and troubleshoot common issues with trimmer machines?

Daily Maintenance:

- Clean the blade and machine components to remove fabric residue.

- Lubricate moving parts to ensure smooth operation.

- Check belt tension and adjust as needed.

Troubleshooting:

- Uneven trimming: Check blade condition, fabric alignment, and machine settings.

- Fabric snagging: Inspect blade sharpness and ensure proper feed rate.

- Machine overheating: Check ventilation, air flow, and electrical connections.

3. Describe the different safety precautions to observe when operating trimmer machines?

- Wear appropriate safety gear (gloves, goggles, earplugs).

- Keep hands clear of moving blades.

- Ensure proper machine grounding to prevent electrical accidents.

- Be aware of the surroundings and potential hazards.

- Follow lockout/tagout procedures when performing maintenance.

4. How do you ensure the accuracy and consistency of trimming operations?

- Use precision measuring tools and templates.

- Calibrate the trimmer machine regularly.

- Inspect trimmed pieces thoroughly for defects or variations.

- Maintain a clean and organized work area.

- Follow established quality control standards.

5. Can you describe the different types of blades used in trimmer machines and their specific applications?

- Straight blades: General-purpose trimming, straight cuts.

- Curved blades: Curved cuts, shaping, and contouring.

- Rotary blades: Fast, continuous trimming.

- Oscillating blades: Precise trimming of delicate materials.

- Ultrasonic blades: Non-contact trimming, prevents fraying.

6. How do you handle deviations from specified trimming parameters?

- Recheck the specifications and ensure they are clearly understood.

- Inspect the fabric and machine settings to identify the root cause.

- Make necessary adjustments or consult with supervisors.

- Document the deviations and corrective actions taken.

- Inform quality control and ensure compliance with standards.

7. What is the importance of blade sharpness in trimming operations?

- Sharp blades provide precise and clean cuts.

- Dull blades can cause ragged edges, tearing, and increased fabric waste.

- Regular blade sharpening ensures optimal performance and quality.

- Blunt blades require more force and can damage the machine.

8. How do you prioritize tasks and manage multiple trimming orders?

- Establish a clear work schedule and prioritize orders based on deadlines.

- Communicate with production planners to coordinate machine availability.

- Utilize checklists and tracking systems to monitor order progress.

- Delegate tasks to team members if necessary.

- Adapt to changing priorities and adjust schedule accordingly.

9. Describe a situation where you had to resolve a complex trimming issue?

Provide a specific example of a problem you encountered, the steps you took to diagnose and resolve it, and the outcome.

10. How do you stay updated on best practices and advancements in trimming technology?

- Attend industry workshops and conferences.

- Consult with equipment manufacturers and suppliers.

- Read industry publications and online forums.

- Participate in training and certification programs.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimmer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimmer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trimmer Machine Operators are responsible for operating machines that trim, cut, or shape materials such as paper, plastic, or metal. They perform a variety of tasks, including:

1. Machine Operation

Operate and monitor trimming machines in accordance with established procedures.

- Set up and adjust trimming machines to meet production specifications.

- Monitor machine performance and make necessary adjustments to ensure proper operation.

2. Material Handling

Handle and feed materials through trimming machines.

- Inspect materials for defects and remove any that do not meet specifications.

- Unload finished products from trimming machines and stack them neatly.

3. Quality Control

Ensure that trimmed materials meet quality standards.

- Visually inspect trimmed materials for defects and reject any that do not meet standards.

- Use measuring tools to verify that trimmed materials are within specified tolerances.

4. Safety and Maintenance

Follow safety procedures and maintain a clean and safe work area.

- Wear appropriate safety gear and follow all safety protocols.

- Maintain trimming machines by performing regular inspections and cleaning.

Interview Tips

To ace a Trimmer Machine Operator interview, it’s important to prepare thoroughly and highlight your relevant skills and experience. Here are a few tips to help you succeed:

1. Research the Company

Familiarize yourself with the company’s website, history, and products or services. This will show the interviewer that you’re genuinely interested in the position and the company.

- Research the specific industry and market that the company operates in.

- Identify any recent news or developments related to the company.

2. Practice Your Answers

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Rehearse your answers out loud to gain confidence and clarity.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Focus on highlighting your skills and experience that are most relevant to the job.

3. Highlight Your Skills

Emphasize your technical skills in operating trimming machines, as well as your attention to detail and commitment to quality. Also, mention any relevant experience in material handling, inspection, or safety procedures.

- Quantify your accomplishments and use specific examples to demonstrate your impact.

- Explain how your skills and experience make you a suitable candidate for the role.

4. Be Enthusiastic and Positive

Convey your enthusiasm for the position and the opportunity to contribute to the company. Maintain a positive attitude throughout the interview and show that you’re eager to learn and grow within the organization.

- Smile, make eye contact, and speak confidently.

- Ask thoughtful questions that demonstrate your interest in the role and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trimmer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!