Are you gearing up for an interview for a Trimmer Sawyer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Trimmer Sawyer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

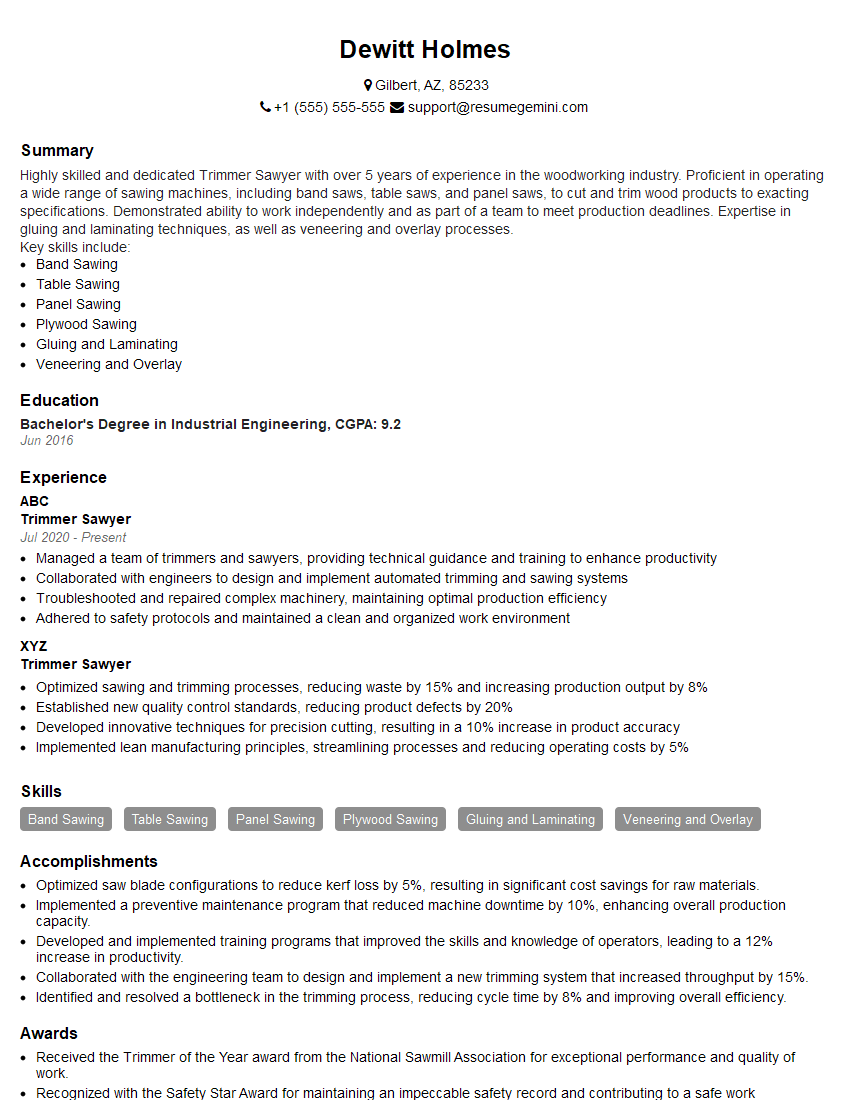

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimmer Sawyer

1. How do you ensure that you are cutting the lumber to the correct dimensions?

To ensure accurate cutting, I utilize various techniques:

- Calibrated Equipment: I regularly calibrate my saws and measuring tools to maintain precision.

- Measuring Templates: I employ measuring templates or jigs to ensure consistent dimensions across multiple cuts.

- Visual Inspection: I visually inspect each cut to verify its accuracy before moving on to subsequent operations.

- Quality Control: I implement a strict quality control process to inspect the finished product and identify any deviations from specifications.

2. What is the proper way to set up and operate a saw for trimming lumber?

Machine Setup:

- Blade Selection: Choose the appropriate saw blade for the type of lumber being cut, considering factors such as tooth count and blade sharpness.

- Fence Adjustment: Set the saw fence accurately to ensure parallel cuts and maintain desired dimensions.

- Blade Alignment: Verify that the saw blade is aligned perpendicular to the fence and parallel to the table surface.

Operation:

- Safety Measures: Wear appropriate safety gear, such as eye protection and earplugs, and ensure the saw is properly grounded.

- Feeding the Lumber: Guide the lumber through the saw carefully, maintaining a steady and even pace.

- Cutting Technique: Use a push stick or block to safely apply pressure and control the lumber as it passes through the blade.

- Monitoring and Adjustment: Observe the cutting process and make adjustments to the fence or blade as needed to maintain accuracy.

3. What are the different types of defects that can occur in trimmed lumber, and how do you identify them?

- Warping: Lumber that bends or twists, making it difficult to work with or use in construction.

- Bowing: A curve along the length of the lumber.

- Crook: A curve along the width of the lumber.

- Knots: Imperfections in the grain where branches once grew.

- Splits: Cracks or separations in the wood.

- Checks: Small cracks that occur during drying.

4. How do you maintain and troubleshoot a saw to ensure optimal cutting performance?

Maintenance:

- Blade Sharpening: Regularly sharpen or replace saw blades to maintain cutting efficiency.

- Blade Cleaning: Remove sawdust, pitch, and other debris from the blade to prevent clogging and ensure clean cuts.

- Lubrication: Lubricate moving parts to reduce friction and extend equipment life.

Troubleshooting:

- Rough Cuts: Check for a dull blade, misaligned fence, or improper blade tension.

- Burning: Adjust feed rate or lubricate the blade to reduce friction.

- Kickback: Ensure proper feed technique and use a push stick or block for added safety.

5. What safety precautions should be taken when operating a saw for trimming lumber?

- Use of Safety Gear: Wear eye protection, earplugs, and appropriate clothing.

- Proper Training: Receive thorough training on saw operation and safety protocols.

- Machine Guarding: Ensure that all guards and safety features on the saw are functioning properly.

- Adequate Lighting: Work in a well-lit area to enhance visibility.

- Avoid Loose Clothing: Keep clothing and jewelry away from moving parts of the saw.

- Concentration and Focus: Pay attention to the task at hand and avoid distractions.

6. Can you describe the process of trimming lumber to create a specific shape or profile?

Trimming lumber to a specific shape or profile involves:

- Pattern Creation: Creating a pattern or template of the desired shape.

- Layout: Transferring the pattern onto the lumber, ensuring accurate placement.

- Trimming: Using a saw, router, or other cutting tool to remove excess material and achieve the desired shape.

- Sanding: Smoothing the edges and surfaces of the trimmed lumber.

- Quality Check: Inspecting the finished product to ensure it meets specifications.

7. What factors influence the choice of saw blade for trimming lumber?

- Type of Lumber: Consider the hardness and grain of the lumber being cut.

- Desired Cut: Select blades with appropriate tooth count and geometry for clean or rough cuts.

- Saw Type: Match the blade type to the saw being used, such as circular saw, table saw, or band saw.

- Blade Size: Choose a blade that is compatible with the saw’s arbor or spindle.

- Blade Material: Opt for blades made of durable materials such as carbide or high-speed steel.

8. How do you ensure that the trimmed lumber meets the specified dimensional tolerances?

- Accurate Measurements: Use calibrated measuring tools and jigs to verify dimensions.

- Precise Cutting: Utilize sharp and well-maintained saw blades to achieve clean and precise cuts.

- Quality Control: Implement a quality control process to inspect trimmed lumber against specifications.

- Continuous Monitoring: Regularly check and adjust equipment settings to maintain accuracy throughout the trimming process.

9. What techniques can be used to improve the efficiency of trimming lumber operations?

- Optimized Cutting Sequences: Plan cutting orders to minimize unnecessary handling and movement of lumber.

- Batch Processing: Trim multiple pieces of lumber simultaneously to save time.

- Automation: Consider using automated saws or trimming lines to enhance speed and productivity.

- Ergonomic Workstations: Design workstations to reduce fatigue and maximize comfort, leading to increased efficiency.

10. How do you stay up-to-date on the latest trimming techniques and industry best practices?

- Industry Publications: Regularly read trade magazines and technical journals.

- Conferences and Training: Attend industry events and workshops to learn about new techniques and equipment.

- Online Resources: Utilize online forums and websites to connect with other professionals and access industry knowledge.

- Collaboration with Colleagues: Share ideas and best practices with colleagues to foster continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimmer Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimmer Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Trimmer Sawyer plays a crucial role in the manufacturing industry, specializing in operating and maintaining sawmill machinery to cut and trim wood into specified dimensions. Their responsibilities encompass various aspects of the production process, ensuring the efficient and high-quality output of lumber products.

1. Operating and Maintaining Sawmill Machinery

Trimmer Sawyers are skilled in operating a range of sawmill equipment, including trimmers, saws, and conveyors. Their expertise lies in setting up and calibrating these machines to achieve precise cuts and consistent dimensions, maximizing lumber yield and minimizing waste.

2. Cutting and Trimming Lumber

The primary function of a Trimmer Sawyer is to cut and trim logs and lumber to meet specific customer requirements. They analyze blueprints and specifications to determine the necessary measurements and angles for each cut. Using their specialized knowledge and equipment, they execute these cuts with precision, ensuring the accuracy and quality of the finished products.

3. Quality Control and Inspection

Trimmer Sawyers are responsible for maintaining high standards of quality throughout the production process. They conduct regular inspections of lumber products to verify compliance with specifications, identify defects, and ensure that only high-quality lumber is released for further processing or sale.

4. Machine Maintenance and Troubleshooting

To ensure optimal productivity and safety, Trimmer Sawyers are responsible for routine maintenance and troubleshooting of sawmill machinery. They perform lubrication, cleaning, and adjustments to keep equipment in good working order. In the event of breakdowns or malfunctions, they diagnose and resolve issues to minimize downtime and maintain production efficiency.

Interview Tips

Preparing for an interview as a Trimmer Sawyer requires a well-rounded approach. Here are some tips to help you ace the interview and showcase your skills and experience:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific Trimmer Sawyer position. Familiarity with their operations, products, and industry standing will demonstrate your interest and preparedness.

- Visit the company’s website to learn about their history, mission, and products.

- Read industry publications and articles to stay informed about current trends and best practices.

- Utilize social media platforms like LinkedIn to connect with current or former employees and gain insights into the company culture.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are directly relevant to the Trimmer Sawyer role. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Discuss your proficiency in operating and maintaining sawmill machinery, including trimmers, saws, and conveyors.

- Provide examples of your ability to cut and trim lumber to precise specifications, ensuring high quality and minimal waste.

- Share your experience in conducting quality inspections and identifying defects, highlighting your commitment to quality control.

- Describe your troubleshooting and problem-solving skills, emphasizing your ability to resolve machine malfunctions and minimize downtime.

3. Demonstrate Safety Consciousness

Safety is paramount in the sawmill industry. Emphasize your safety consciousness and adherence to workplace safety regulations. Share examples of your proactive approach to ensuring a safe working environment.

- Discuss your understanding of proper machine operation and safety protocols.

- Explain your experience with using personal protective equipment (PPE) and maintaining a clean and organized work area.

- Highlight your knowledge of emergency procedures and your willingness to participate in safety training and drills.

4. Prepare Industry-Specific Questions

Asking industry-specific questions during the interview demonstrates your knowledge and interest in the field. Prepare questions that show you have researched the company and are eager to learn more about their operations.

- Inquire about the company’s approach to sustainability and environmental responsibility.

- Ask about their production capacity and the types of lumber products they specialize in.

- Show interest in their plans for future growth or investment in new technologies.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trimmer Sawyer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.