Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trimming Machine Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

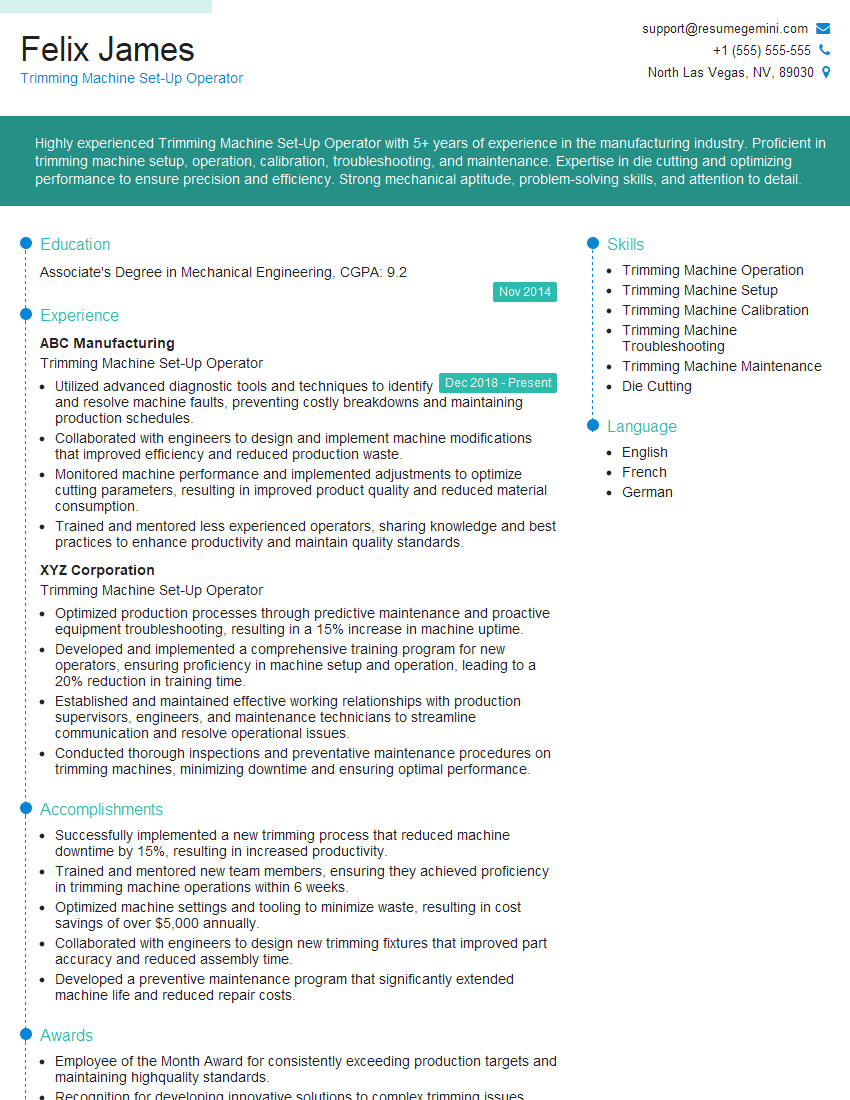

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trimming Machine Set-Up Operator

1. Explain the process of setting up and operating a trimming machine.

- Inspect the machine and ensure it is in good working condition.

- Mount the appropriate trimming blade and adjust the blade height.

- Install the workpiece and secure it in place.

- Set the feed rate and spindle speed.

- Start the machine and monitor the trimming process.

2. What are the safety precautions to consider when operating a trimming machine?

Proper Training and Clothing

- Receive thorough training on the machine’s operation and safety procedures.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

Machine Safety

- Ensure the machine is properly grounded to prevent electrical hazards.

- Keep the work area clean and free of tripping hazards.

- Never operate the machine with unguarded moving parts.

- Use proper lifting techniques when handling heavy workpieces.

Blade Safety

- Inspect blades regularly for wear and damage.

- Use the proper blade for the material being trimmed.

- Never operate the machine with a loose or dull blade.

- Store blades safely when not in use.

3. How do you troubleshoot common problems with a trimming machine?

- Blade dull or worn: Replace the blade.

- Blade not aligned properly: Realign the blade.

- Workpiece not secured properly: Secure the workpiece properly.

- Feed rate or spindle speed too high or too low: Adjust the feed rate or spindle speed.

- Machine overheating: Allow the machine to cool down or check for ventilation issues.

4. What types of trimming machines have you worked with?

- Manual trimming machines

- Semi-automatic trimming machines

- Fully automatic trimming machines

5. What experience do you have with different types of materials and their trimming requirements?

- Metals (e.g., steel, aluminum, brass)

- Plastics (e.g., ABS, PVC, polycarbonate)

- Wood (e.g., oak, maple, pine)

- Composite materials (e.g., fiberglass, carbon fiber)

6. How do you ensure the accuracy and precision of your trimming operations?

- Use precision measuring tools and follow established procedures.

- Check the workpiece regularly during the trimming process.

- Calibrate the machine regularly according to the manufacturer’s specifications.

7. What are the quality control procedures you follow to ensure the quality of trimmed parts?

- Inspect the trimmed parts for burrs, excess material, or other defects.

- Use gauges and other measuring tools to verify the dimensions and tolerances of the parts.

- Maintain records of quality checks and corrective actions taken.

8. How do you handle high-volume trimming operations?

- Utilize automated or semi-automated trimming machines.

- Implement efficient workflow processes to minimize downtime.

- Coordinate with other team members to ensure a smooth production flow.

9. What is your experience with preventive maintenance and repairs on trimming machines?

- Perform regular maintenance tasks, such as cleaning, lubrication, and blade sharpening.

- Identify potential problems early on and take corrective actions.

- Collaborate with maintenance technicians for major repairs or overhauls.

10. How do you stay updated on the latest trimming technologies and industry best practices?

- Attend industry conferences and workshops.

- Read technical publications and online resources.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trimming Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trimming Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Trimming Machine Set-Up Operator is responsible for setting up, operating, and maintaining trimming machines used in the production of various products. The primary duties include:

1. Machine Setup and Calibration

Setting up and calibrating trimming machines according to specified tolerances and production requirements.

- Installing and adjusting cutting tools, dies, and jigs.

- Ensuring proper machine alignment and calibration for accurate trimming.

2. Material Handling

Loading and unloading materials into trimming machines efficiently and safely.

- Inspecting materials for defects and ensuring they meet specifications.

- Adjusting feed rates and tension settings to optimize material flow.

3. Machine Operation and Monitoring

Operating trimming machines and closely monitoring the trimming process.

- Making adjustments to machine settings based on material properties and production requirements.

- Identifying and resolving minor machine malfunctions and troubleshooting issues promptly.

4. Quality Control

Inspecting trimmed products for quality and compliance with specifications.

- Using measuring tools and gauges to verify dimensional accuracy and surface finish.

- Identifying and reporting any deviations from quality standards.

5. Machine Maintenance

Performing routine maintenance and cleaning of trimming machines to ensure optimal performance.

- Lubricating moving parts and checking for wear and tear.

- Replacing worn or damaged components as needed.

Interview Tips

To ace an interview for a Trimming Machine Set-Up Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and specific requirements for the Trimming Machine Set-Up Operator role. This will demonstrate your interest and preparation.

- Visit the company’s website and read about their mission, values, and products.

- Research the industry and identify key trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Describe your experience in setting up, operating, and maintaining trimming machines.

- Provide examples of how you improved efficiency or reduced production errors.

3. Demonstrate Attention to Detail and Quality

Convey your commitment to accuracy and quality by highlighting your attention to detail and ability to consistently meet specifications. Provide examples of how you have identified and resolved quality issues.

- Explain how you use measuring tools and gauges to ensure precision.

- Describe any quality improvement initiatives you have participated in.

4. Emphasize Troubleshooting Abilities

Trimming Machine Set-Up Operators often need to troubleshoot and resolve machine issues. Discuss your problem-solving skills and provide examples of how you have identified and fixed equipment malfunctions.

- Describe a time when you diagnosed and resolved a significant machine issue.

- Explain your approach to troubleshooting and problem-solving.

5. Express Enthusiasm and Learning Agility

Convey your enthusiasm for working in the manufacturing industry and your willingness to learn new technologies or processes. Indicate that you are adaptable and eager to contribute to the team’s success.

- Explain why you are interested in the Trimming Machine Set-Up Operator role.

- Describe your desire to stay updated with industry best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trimming Machine Set-Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.