Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Triple Air-Valve Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

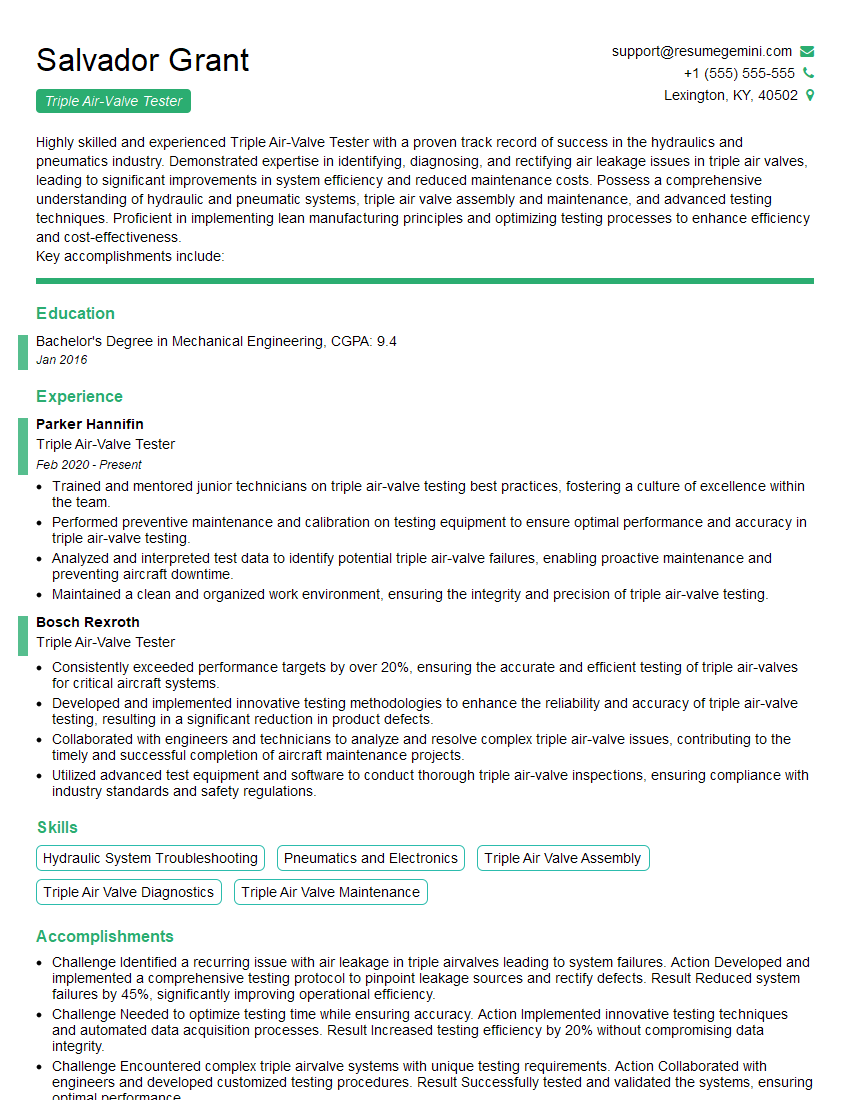

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Triple Air-Valve Tester

1. Explain the procedure to calibrate a triple air valve tester?

The calibration procedure for a triple air valve tester involves the following steps:

- Connect the tester to a compressed air source and a calibrated pressure gauge.

- Set the pressure to the specified test pressure and check the reading on the pressure gauge to ensure accuracy.

- Apply the test pressure to the tester and observe the valve’s response time and exhaust rate.

- Record the test results and compare them to the manufacturer’s specifications.

- Adjust the tester’s settings as necessary to ensure that it meets the required specifications.

2. What are the different types of triple air valves?

Pressure-reducing valves

- Reduce the pressure of compressed air from a higher pressure source to a lower pressure

- Used in applications such as air tools, spray guns, and pneumatic actuators

Check valves

- Allow air to flow in only one direction

- Used to prevent backflow of air in systems

Quick exhaust valves

- Rapidly exhaust air from a system

- Used in applications where quick response is required, such as braking systems

3. What are the key performance characteristics of a triple air valve tester?

The key performance characteristics of a triple air valve tester include:

- Accuracy

- Repeatability

- Response time

- Range of test pressures

- Ease of use

4. What are the common causes of triple air valve failure?

The common causes of triple air valve failure include:

- Wear and tear

- Contamination

- Improper adjustment

- Corrosion

- Manufacturing defects

5. What is the difference between a triple air valve tester and a pressure gauge?

A triple air valve tester measures the response time and exhaust rate of a triple air valve, while a pressure gauge measures the pressure in an air system.

- Triple air valve tester:

- Measures the time it takes for a valve to open and close

- Measures the rate at which air is exhausted from the valve

- Used to ensure that valves are working properly

- Pressure gauge:

- Measures the pressure in an air system

- Used to ensure that air pressure is within the proper range

- Does not measure valve response time or exhaust rate

6. What are the safety precautions that should be taken when testing triple air valves?

The following safety precautions should be taken when testing triple air valves:

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Use a properly calibrated triple air valve tester.

- Connect the triple air valve tester to the valve under test using the correct fittings and hoses.

- Never exceed the maximum pressure rating of the triple air valve or the tester.

- Be aware of the location of the exhaust port and ensure that it is directed away from personnel and equipment.

7. What are the different types of triple air valve tests that can be performed?

The different types of triple air valve tests that can be performed include:

- Leakage test:

- Checks for leaks in the valve body, seals, and gaskets

- Response time test:

- Measures the time it takes for the valve to open and close

- Exhaust rate test:

- Measures the rate at which air is exhausted from the valve

- Pressure drop test:

- Measures the pressure drop across the valve when it is open

8. What are the advantages of using a triple air valve tester?

The advantages of using a triple air valve tester include:

- Improved safety:

- Can help to identify faulty valves before they cause a failure

- Increased efficiency:

- Can help to reduce downtime by preventing valve failures

- Lower maintenance costs:

- Can help to identify valves that need to be repaired or replaced, preventing more costly repairs in the future

9. What are the limitations of using a triple air valve tester?

The limitations of using a triple air valve tester include:

- Can only test valves that are accessible:

- Valves that are buried or located in difficult-to-reach areas may not be able to be tested

- May not be able to detect all valve failures:

- Some valve failures may only occur under specific operating conditions that cannot be replicated during testing

- Can be time-consuming:

- Testing multiple valves can take significant time, especially if the valves are located in different areas

10. What are the future trends in triple air valve testing?

The future trends in triple air valve testing include:

- Increased use of automated testing:

- Automated testing can reduce the time and effort required to test valves

- Development of new testing methods:

- New testing methods are being developed to improve the accuracy and reliability of valve testing

- Greater focus on condition-based maintenance:

- Condition-based maintenance involves testing valves only when there is an indication that they may be failing, which can help to reduce downtime and maintenance costs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Triple Air-Valve Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Triple Air-Valve Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Triple Air-Valve Tester is responsible for testing, adjusting and repairing triple air valves on railway cars. They work with various tools and equipment and must be able to troubleshoot and resolve any issues that may arise. The key job responsibilities of a Triple Air-Valve Tester include:

1. Testing and Troubleshooting

Testing triple air valves to ensure proper operation following industry standards

- Using specialized testing equipment to identify any deviations from the standard

- Troubleshooting any issues identified during testing and determining the necessary repairs

2. Adjustments and Repairs

Making necessary adjustments and repairs to ensure that triple air valves are functioning optimally

- Replacing worn or damaged components

- Reassembling and testing triple air valves after repairs

3. Documentation and Reporting

Maintaining accurate records of all testing, adjustments, and repairs performed

- Preparing reports summarizing test results, repairs, and any recommendations

- Ensuring that all documentation is up-to-date and meets regulatory requirements

4. Safety and Compliance

Adhering to safety regulations and guidelines while performing testing and repairs

- Wearing appropriate safety gear

- Following established procedures for handling and storing hazardous materials

Interview Tips

Preparing for an interview for a Triple Air-Valve Tester position requires research, practice, and understanding of the industry. Here are some interview tips to help candidates ace their interview:

1. Research the Company and Industry

Research the company’s reputation, values, and recent developments to demonstrate your interest and understanding

- Visit the company’s website and read industry publications

- Identify current trends and challenges within the railway maintenance sector

2. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”

- Craft concise and engaging answers that highlight your relevant skills and experience

- Use the STAR method (Situation, Task, Action, Result) to structure your responses

3. Showcase Your Technical Expertise

Emphasize your knowledge of triple air valves and industry testing procedures

- Explain how you have applied your technical skills to solve problems

- Discuss your understanding of railway safety regulations

4. Highlight Your Safety Awareness

Demonstrate your commitment to safety in the workplace

- Describe your experience with safety protocols and risk assessments

- Explain how you prioritize safety in your daily work

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Triple Air-Valve Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!