Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trolley Wire Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

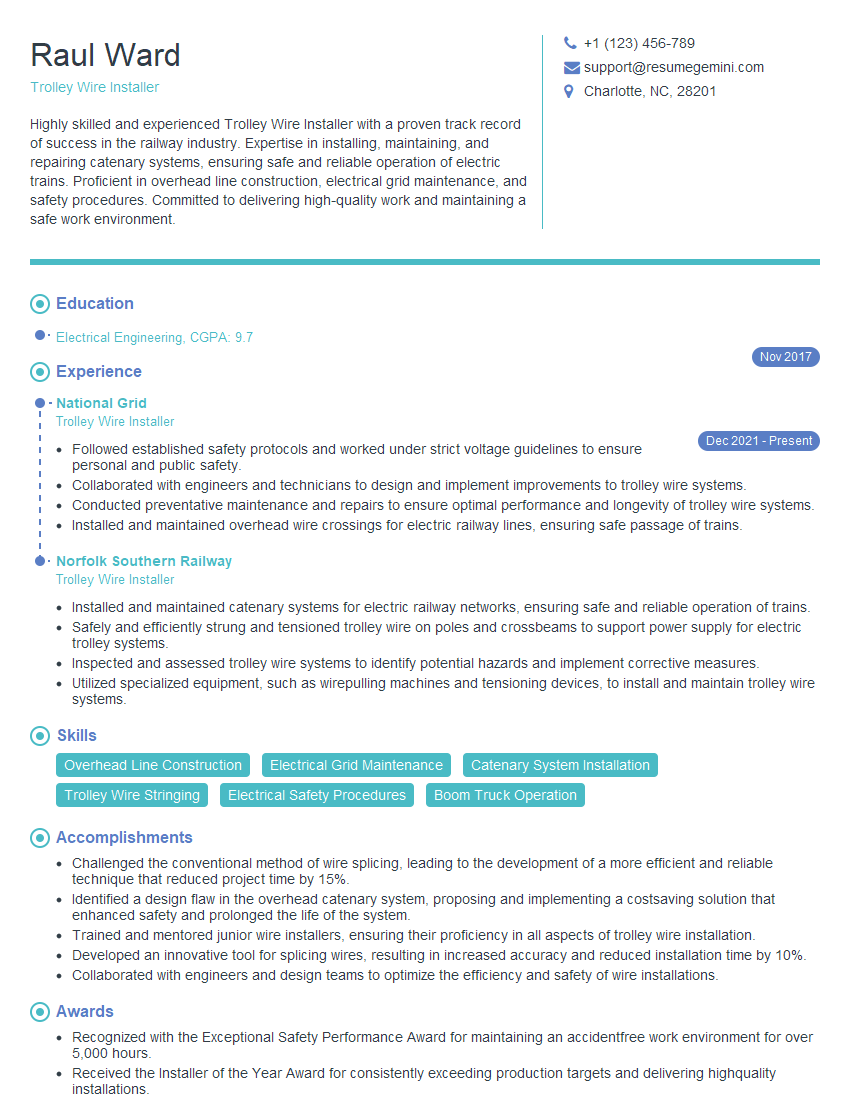

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trolley Wire Installer

1. Explain the process of installing a trolley wire system?

The process of installing a trolley wire system generally involves the following steps:

- Surveying the site: Determine the location of the trolley wire system, including the poles, wires, and other components.

- Installing the poles: Place the poles at the designated locations and secure them in the ground.

- Stringing the wires: Run the trolley wire and other wires between the poles, ensuring proper tension and alignment.

- Installing the hangers: Attach hangers to the wires to support the trolley wire and maintain its position.

- Connecting the system to the power source: Establish a connection between the trolley wire system and the electrical grid or other power source.

- Testing and commissioning: Conduct tests to verify the functionality and safety of the system before putting it into operation.

2. Describe the different types of trolley wire systems?

Overhead trolley wire systems

- Used in various applications, including electric trains, trams, and industrial cranes.

- Consist of a single wire or multiple wires suspended overhead.

Conduit trolley wire systems

- Enclosed in a conduit or protective covering.

- Provide protection from the elements and potential hazards.

Inverted trolley wire systems

- The trolley wire is positioned below the running rails.

- Often used in underground mining operations.

3. What are the safety precautions to consider when working on trolley wire systems?

Working on trolley wire systems requires strict adherence to safety precautions, including:

- Ensuring proper grounding: Grounding the system and equipment to prevent electrical hazards.

- Wearing appropriate PPE: Using personal protective equipment such as insulated gloves, safety glasses, and a hard hat.

- Maintaining safe clearances: Keeping a safe distance from energized wires and components.

- Following lockout/tagout procedures: Isolating power before performing maintenance or repairs.

- Regular inspections and maintenance: Inspecting and maintaining the system to identify and address any potential issues.

4. How do you calculate the tension required for trolley wire installation?

Calculating the tension required for trolley wire installation involves considering factors such as:

- Wire material and diameter: Different materials and diameters have different tension requirements.

- Span length: The distance between poles or other support structures.

- Temperature: Temperature affects the tension of the wire.

- Wind loading: The anticipated wind forces on the wire.

- Permissible sag: The allowable amount of deflection in the wire.

5. Explain the techniques used to join trolley wires?

Various techniques are used to join trolley wires, including:

- Mechanical splices: Using connectors or clamps to mechanically join the wires.

- Electrical splices: Welding or soldering the wires together to create an electrical connection.

- Compression sleeves: Using sleeves to compress the wires together, creating a secure and conductive joint.

6. Describe the methods for anchoring trolley wires?

Anchoring trolley wires involves securing them to structures or poles using methods such as:

- Dead-end anchors: Used at the ends of the trolley wire to prevent movement.

- Strain insulators: Insulators that allow for tension adjustment without compromising electrical isolation.

- Tensioning devices: Devices that maintain the desired tension in the wire.

7. Explain the importance of regular maintenance and inspection of trolley wire systems?

Regular maintenance and inspection of trolley wire systems are crucial for:

- Ensuring safety: Identifying and addressing potential hazards or issues that could compromise safety.

- Maintaining performance: Ensuring the system operates efficiently and reliably.

- Extending lifespan: Regular maintenance helps extend the lifespan of the system by preventing premature failures.

- Compliance: Meeting regulatory requirements and industry standards for safety and maintenance.

8. What are the common problems encountered during trolley wire installation and how do you resolve them?

Some common problems during trolley wire installation and their potential solutions include:

- Sagging wires: Adjust the tension or install additional supports to prevent excessive sagging.

- Arcing or sparking: Check for damaged insulation or loose connections and make necessary repairs.

- Corrosion: Apply protective coatings or use corrosion-resistant materials to prevent corrosion.

- Wear and tear: Regularly inspect and replace worn components to ensure proper operation.

9. Describe the tools and equipment used in trolley wire installation?

Essential tools and equipment used in trolley wire installation include:

- Stringing equipment: Used to pull and tension the wires.

- Insulated tools: To handle energized components safely.

- Tensioning devices: To adjust and maintain the tension in the wires.

- Measuring and leveling tools: To ensure accurate installation.

- Safety gear: Personal protective equipment such as gloves, safety glasses, and a hard hat.

10. Explain the importance of following manufacturer’s instructions and industry standards when installing trolley wire systems?

Adhering to manufacturer’s instructions and industry standards is critical because:

- Safety: Following guidelines helps ensure safe installation and operation.

- Performance: Proper installation methods optimize the performance and efficiency of the system.

- Reliability: Adhering to standards reduces the risk of failures and ensures long-term reliability.

- Compliance: Meeting industry standards demonstrates compliance with regulatory requirements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trolley Wire Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trolley Wire Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trolley Wire Installers play a vital role in maintaining the infrastructure for electric rail systems. Their primary responsibility is to install, maintain, and repair trolley wires that provide power to electric trains and trams.

1. Installation and Maintenance of Overhead Trolley Wires

Installers are responsible for stringing, tensioning, and fastening trolley wires to support structures along rail lines. They ensure proper alignment and electrical continuity to provide a reliable power supply to trains.

- Install and replace trolley wires, hangers, insulators, and other components.

- Adjust tension and alignment to ensure proper electrical contact and minimize wear.

2. Inspection and Troubleshooting

Regularly inspect trolley wire systems for damage, wear, and other potential issues. They identify and repair any faults promptly to prevent disruptions.

- Visually inspect wires, insulators, and support structures for signs of damage or corrosion.

- Use specialized tools to detect electrical faults and troubleshoot problems.

3. Equipment Operation

Operate specialized equipment such as tensioning machines, wire cutters, and aerial lifts. They use these tools to safely and efficiently perform installation and maintenance tasks.

- Use tensioning machines to adjust wire tension and alignment.

- Utilize aerial lifts to access overhead wires and perform repairs at height.

4. Safety Protocols

Adhere to strict safety procedures while working with high-voltage electrical equipment. They wear appropriate protective gear and follow established protocols to minimize risks.

- Wear insulated gloves, hard hats, and other safety gear.

- Follow lockout/tagout procedures to prevent electrical accidents.

Interview Tips

Preparing thoroughly for a Trolley Wire Installer interview can greatly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Trolley Wire Installer role. This will help you tailor your answers and demonstrate your understanding of the job.

- Visit the company website and review their mission statement and recent news.

- Study the job description thoroughly and identify the key skills and responsibilities.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience and skills that are directly relevant to the role. Quantify your accomplishments whenever possible.

- Showcase your experience in installing, maintaining, and repairing trolley wire systems.

- Mention any certifications, training, or previous projects that demonstrate your expertise.

3. Prepare for Technical Questions

Expect technical questions related to trolley wire installation, maintenance, and troubleshooting. Review common procedures and best practices.

- Explain the process of installing and tensioning trolley wires.

- Describe the different types of insulators used in trolley wire systems.

4. Demonstrate Safety Awareness

Emphasize your commitment to safety and adherence to established protocols. Describe your experience with electrical safety procedures and PPE.

- Explain the importance of wearing proper safety gear and following lockout/tagout procedures.

- Describe your experience working with high-voltage equipment.

5. Practice Your Answers

Rehearse your answers to common interview questions in front of a mirror or with a friend. This will help you deliver your responses confidently and clearly.

- Practice introducing yourself and explaining your qualifications.

- Prepare answers to questions about your experience and technical knowledge.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Trolley Wire Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.