Are you gearing up for a career in Trommel Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Trommel Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

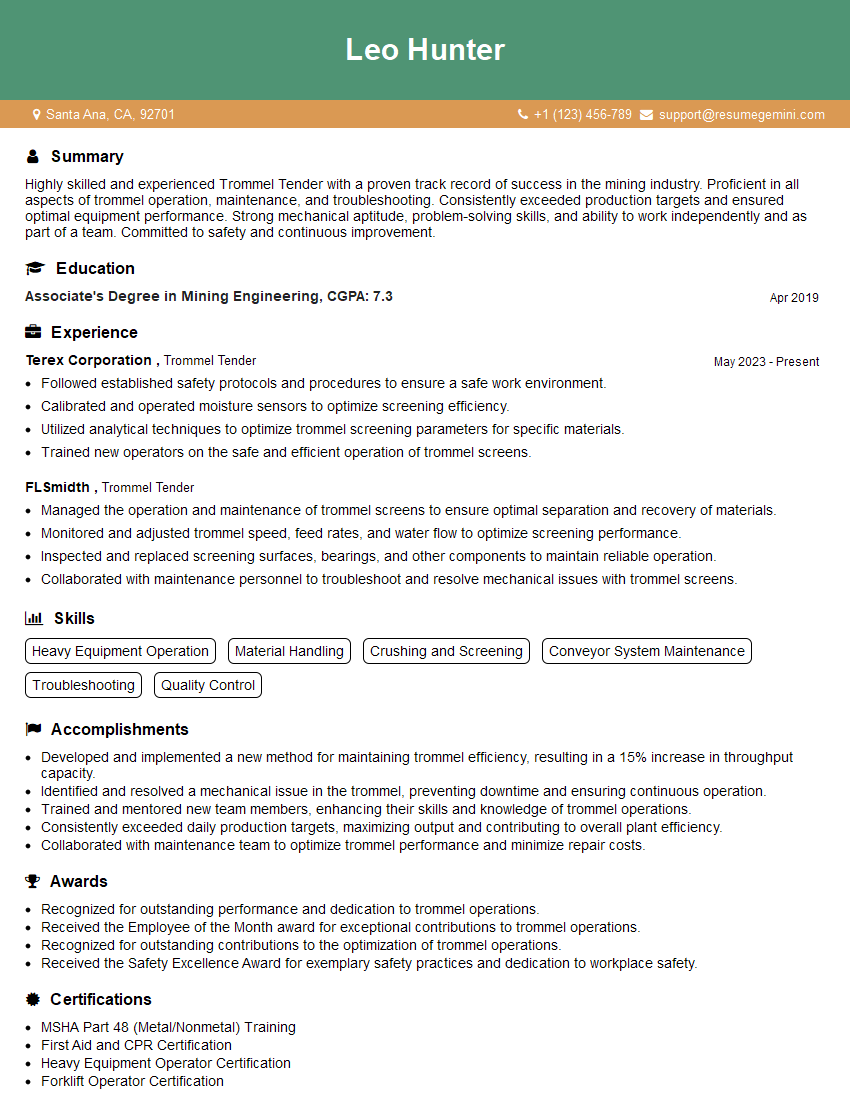

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trommel Tender

1. What is a Trommel Tender and what are its main responsibilities?

A Trommel Tender is responsible for operating and maintaining a trommel screen, a machine used in the mining and construction industries to separate materials based on size. The main responsibilities of a Trommel Tender include:

- Maintaining and inspecting the trommel screen to ensure it is in good working condition

- Setting up and operating the trommel screen, including adjusting the speed and angle of the screen to achieve the desired separation of materials

- Ensuring the proper functioning of the trommel screen by making necessary adjustments and repairs

- Monitoring the performance of the trommel screen and reporting any issues or concerns

- Following safety regulations and ensuring a safe work environment while operating the trommel screen

2. What are the different types of trommel screens and their applications?

Rotary Trommel Screen

- Cylindrical shape with a perforated screen surface

- Used for separating materials based on size, such as sand, gravel, and compost

Differential Speed Trommel Screen

- Similar to rotary trommel screens but with multiple rotating speeds

- Used for more precise separation of materials with different size ranges

Grizzly Trommel Screen

- Sturdy construction with heavy-duty bars or rods

- Used for removing oversized materials or debris from bulk materials

Washing Trommel Screen

- Features a water spray system to clean materials as they pass through the screen

- Used in applications where materials need to be washed, such as in mining and recycling

3. Can you describe the different components of a trommel screen and their functions?

- Drum or Cylinder: The rotating part of the screen that holds the perforated screen surface

- Screen Surface: A perforated metal sheet with varying hole sizes to separate materials

- Inlet and Outlet: Openings where materials enter and exit the drum, respectively

- Support Structure: The framework that supports the drum and other components

- Drive Mechanism: The motor and gearbox that rotate the drum

- Sensors: Devices that monitor the performance of the screen, such as speed and vibration

4. How do you troubleshoot common problems that arise when operating a trommel screen?

- Blockage: Inspect the screen surface for any obstructions or build-up of material

- Incorrect Material Separation: Adjust the screen speed, angle, or mesh size to achieve the desired separation

- Excessive Vibration: Check the balance of the drum, inspect the bearings, and ensure proper alignment

- Electrical Issues: Inspect wires, connections, and electrical components, and consult with an electrician if necessary

5. What safety precautions should be taken when working with a trommel screen?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Keep the area around the screen clear of obstacles and tripping hazards

- Lock out and tag out the screen before performing any maintenance or repairs

- Follow proper lockout/tagout procedures as per company regulations

- Be aware of moving parts and pinch points, and maintain a safe distance while operating the screen

6. What are the benefits of preventive maintenance for a trommel screen, and how often should it be performed?

- Improved Performance: Regular maintenance ensures optimal operation and efficiency

- Reduced Downtime: Proactively identifying and fixing issues can prevent unexpected breakdowns

- Extended Lifespan: Proper care and maintenance can prolong the life of the screen

- Enhanced Safety: Regular inspections help detect potential hazards and reduce the risk of accidents

- Cost Savings: Preventive maintenance is less expensive than reactive maintenance or repairs

The frequency of preventive maintenance should be determined based on the manufacturer’s recommendations and the operating conditions of the screen, typically every 3-6 months.

7. What are the different types of materials that can be processed using a trommel screen?

- Sand and Gravel

- Compost and Soil

- Coal and Minerals

- Construction and Demolition Debris

- Municipal Solid Waste

- Wood Chips and Biomass

8. What are the factors to consider when selecting a trommel screen for a specific application?

- Material properties (size, shape, density)

- Desired separation size and efficiency

- Capacity and throughput requirements

- Operating environment and available space

- Budget and available resources

9. What is the role of a Trommel Tender in maintaining a clean and safe work environment?

- Keep the work area around the trommel screen clean and free of debris

- Dispose of waste materials properly

- Report any spills or leaks promptly

- Follow proper safety protocols and wear appropriate PPE

- Maintain good housekeeping practices to prevent accidents and injuries

10. Why are you interested in this Trommel Tender position, and what makes you a suitable candidate for the role?

I am eager to obtain the Trommel Tender position at your esteemed company due to my strong understanding of trommel screen operations and maintenance. My previous experience in a similar role has equipped me with the necessary skills and knowledge to excel in this position.

My responsibilities included operating, maintaining, and troubleshooting a trommel screen used in a mining application. I have a deep understanding of the different types of trommel screens, their components, and their applications. I am also proficient in identifying and resolving common issues that arise during operation.

Furthermore, I am a highly motivated and safety-conscious individual with a strong work ethic. I am eager to contribute my skills and experience to your team and support the efficient operation of your trommel screen.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trommel Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trommel Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Trommel Tender plays a vital role in the operation and maintenance of a trommel, a rotating cylindrical screening device used in various industries, such as mining, recycling, and waste management.

1. Trommel Operation and Maintenance

The primary responsibility of a Trommel Tender is to operate and maintain the trommel, ensuring it runs smoothly and efficiently. This includes:

- Loading material into the trommel using conveyors or other feeding equipment.

- Monitoring the trommel’s operation, observing material flow and adjusting feed rates as needed.

- Changing screens or other trommel components as required to meet product specifications.

- Performing regular cleaning and lubrication of the trommel, including bearings and other moving parts.

2. Material Inspection and Quality Control

Trommel Tenders are also responsible for inspecting materials processed by the trommel. This involves:

- Visually inspecting materials to ensure they meet quality standards or specifications.

- Taking samples of materials for laboratory testing to verify quality or compliance with regulations.

- Reporting any abnormalities or issues with the material to supervisors or quality control personnel.

3. Equipment Monitoring and Trouble-shooting

Trommel Tenders are expected to monitor the trommel’s performance and identify any potential issues or malfunctions. This includes:

- Observing the operation of equipment, such as conveyors, feeders, and screens, for any signs of wear or damage.

- Listening for unusual noises or vibrations that may indicate equipment problems.

- Responding to alarms or other indicators of potential issues.

- Performing basic troubleshooting and making minor repairs to resolve equipment issues.

4. Safety and Compliance

Safety is paramount for Trommel Tenders. Their responsibilities include:

- Complying with all safety regulations and procedures.

- Wearing appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Ensuring the work area is clean, organized, and free of hazards.

- Reporting any safety concerns or incidents to supervisors.

Interview Tips

Preparing for a Trommel Tender interview can increase your chances of success. Here are some tips to help you stand out:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the industry. Research the company’s website, industry publications, and news articles.

- Understand the company’s values, mission, and products/services.

- Familiarize yourself with industry trends and best practices.

2. Highlight Relevant Experience and Skills

Showcase your experience in operating and maintaining industrial equipment. Emphasize your skills in:

- Equipment operation and troubleshooting.

- Material inspection and quality control.

- Safety procedures and compliance.

- Communication and teamwork.

3. Prepare for Common Interview Questions

Anticipate and prepare for common Trommel Tender interview questions. Here are examples:

- Can you describe your experience in operating and maintaining trommels?

- How do you ensure the quality of materials processed by the trommel?

- Tell me about a time you identified and resolved an equipment issue.

- What safety precautions do you take when operating a trommel?

4. Ask Thoughtful Questions

Asking thoughtful questions shows your engagement and interest in the role. Prepare questions about the company, the role, or the industry.

- What are the company’s growth plans and how does this role fit into them?

- Are there opportunities for professional development or training?

- What are the challenges and opportunities associated with the role?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trommel Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.