Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Truss Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

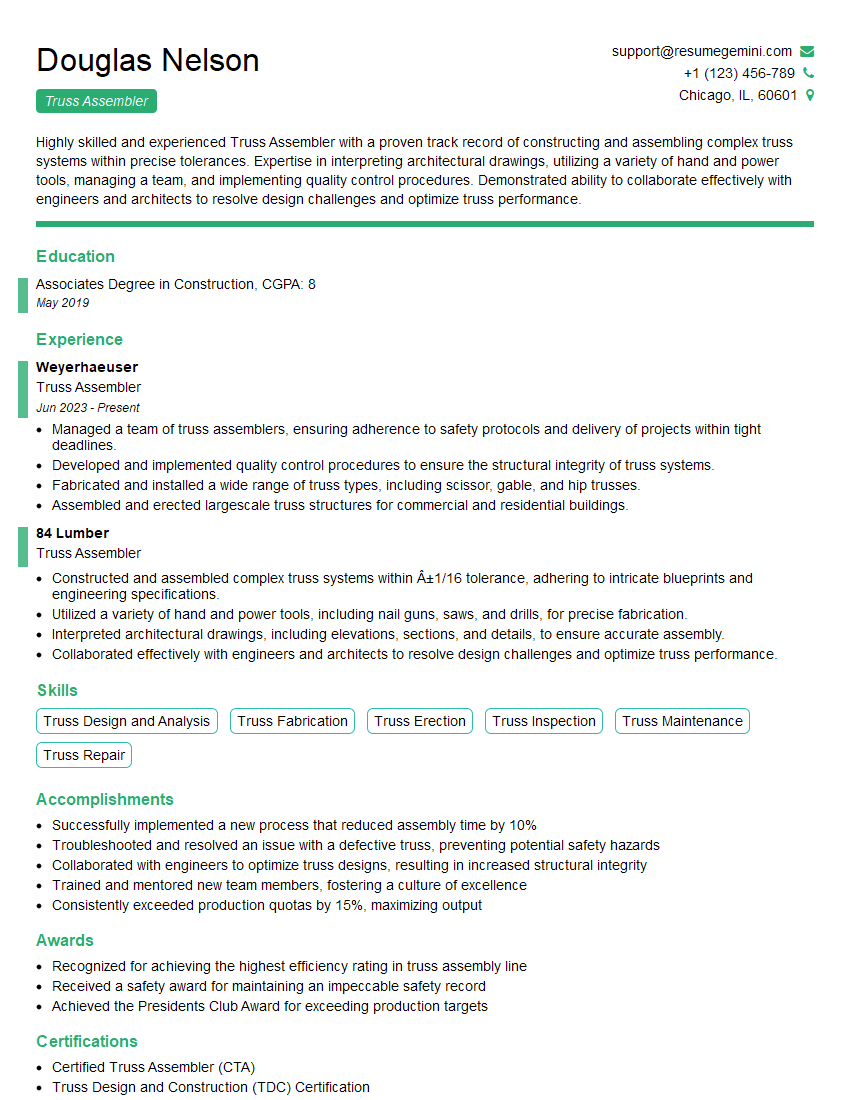

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Truss Assembler

1. Can you describe your understanding of the role of a Truss Assembler?

In my understanding, a Truss Assembler is responsible for constructing and assembling trusses, which are structural components primarily used in the construction of roofs, bridges, and certain types of buildings. The job involves working with various materials such as wood, metal, or composite materials.

2. What are the key technical skills required to be a successful Truss Assembler?

Knowledge of Truss Design and Assembly Techniques

- Understanding of truss designs and their structural properties

- Proficiency in assembly methods, including nailing, bolting, and welding

Material Handling and Fabrication Skills

- Ability to handle and manipulate heavy materials

- Skill in operating fabrication equipment, such as saws, drills, and welding machines

Safety and Quality Standards

- Adherence to safety regulations and industry best practices

- Attention to detail and commitment to maintaining high-quality standards

3. What types of materials are commonly used in truss assembly?

The most common materials used in truss assembly are:

- Wood: Strong and cost-effective, often used in residential and commercial construction

- Metal: Durable and fire-resistant, suitable for larger and more complex structures

- Composite materials: Engineered to combine the strengths of wood and metal, offering improved properties

4. Can you elaborate on the process of assembling a wooden truss?

The process of assembling a wooden truss typically involves the following steps:

- Material Preparation: Cutting and preparing lumber according to the truss design

- Joint Assembly: Connecting the lumber pieces using nails, bolts, or glue

- Truss Shaping: Manually or using jigs to shape the truss into its intended form

- Quality Control: Inspecting the assembled truss to ensure it meets specifications

5. What are the different types of trusses used in construction?

There are various types of trusses used in construction, each suited for specific applications:

- Parallel Chord Truss: Commonly used in residential roofing, with parallel top and bottom chords

- Howe Truss: Features diagonal members that form an X-shape, providing strength and stability

- Scissors Truss: Used in vaulted ceilings, with a scissor-like shape that creates a raised roofline

- Gang Nail Truss: Prefabricated truss with metal plates connecting the members, ensuring high strength

6. How do you ensure the accuracy and quality of your truss assemblies?

To ensure accuracy and quality, I adhere to the following practices:

- Precise Measurements: Using accurate measuring tools and jigs to cut and assemble materials

- Quality Control Checks: Regular inspections throughout the assembly process to identify and correct any discrepancies

- Adherence to Specifications: Following established design specifications and industry standards

- Continuous Improvement: Seeking feedback and implementing improvements to enhance the efficiency and quality of my work

7. What safety measures are important to observe when working as a Truss Assembler?

To ensure a safe work environment, I prioritize the following safety measures:

- Proper Personal Protective Equipment (PPE): Wearing hard hats, safety glasses, gloves, and sturdy footwear

- Material Handling Safety: Using proper techniques for lifting and moving heavy materials to prevent injuries

- Machine Safety: Following safety protocols when operating fabrication equipment, such as saws and drills

- Fall Prevention: Utilizing appropriate ladders and scaffolding for working at heights

8. How do you stay up-to-date with advancements in truss design and assembly techniques?

To stay current with industry advancements, I engage in the following practices:

- Industry Publications and Conferences: Regularly reading trade magazines and attending industry events to learn about new technologies and best practices

- Manufacturer Training: Participating in training programs offered by truss manufacturers to enhance knowledge of their products and assembly methods

- Online Resources: Utilizing online platforms and forums to connect with other professionals and access up-to-date information

9. Can you describe a challenging truss assembly project you have worked on and how you overcame the difficulties?

In one project, I encountered a complex truss design with intricate angles and multiple connection points. To overcome these challenges, I:

- Detailed Planning: Carefully reviewed the design and identified potential areas of difficulty

- Customized Jigs: Fabricated specialized jigs to ensure precise angles and joint alignment

- Team Collaboration: Worked closely with colleagues to develop innovative solutions for the most challenging aspects

10. How do you prioritize tasks and manage your workload when faced with multiple truss assembly orders?

To efficiently manage my workload, I prioritize tasks based on the following criteria:

- Project Deadlines: Giving priority to orders with urgent deadlines to ensure timely delivery

- Material Availability: Considering the availability of materials required for each order to avoid delays

- Team Capacity: Assessing the availability and capabilities of team members to assign tasks effectively

- Quality Standards: Ensuring that each order meets the required quality standards, regardless of its urgency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Truss Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Truss Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Truss Assemblers are responsible for assembling and constructing roof and floor trusses, ensuring that they meet specifications and building codes.

1. Truss Assembly

Assembling trusses according to blueprints and specifications using jigs, fixtures, power tools, and hand tools.

- Cutting and shaping lumber to create truss components.

- Assembling components using nails, screws, or other fasteners.

2. Truss Inspection

Inspecting assembled trusses for accuracy, strength, and compliance with specifications.

- Checking dimensions, angles, and connections.

- Identifying and correcting any errors or defects.

3. Material Handling

Handling and moving lumber, trusses, and other materials safely and efficiently.

- Loading and unloading materials from trucks or trailers.

- Storing materials in designated areas.

4. Equipment Maintenance

Maintaining and calibrating tools and equipment used in truss assembly.

- Cleaning and lubricating power tools.

- Performing minor repairs and adjustments.

Interview Tips

Preparing for an interview for a Truss Assembler position requires a combination of technical understanding and preparation.

1. Research the Company and Industry

Research the company you’re applying to and the truss assembly industry. This knowledge will demonstrate your interest and preparation.

- Visit the company website to learn about their products, services, and culture.

- Review industry publications and news articles to stay informed about trends and best practices.

2. Practice Interview Questions

Common interview questions for Truss Assemblers include:

- Tell me about your experience in truss assembly

- Describe your understanding of truss design and construction principles.

- How do you ensure the accuracy and strength of your trusses?

- What safety protocols do you follow when assembling trusses?

3. Highlight Transferable Skills

If you don’t have direct experience in truss assembly, highlight transferable skills from other industries.

- Emphasize your experience in construction, manufacturing, or related fields.

- Showcase your ability to work with precision, attention to detail, and safety.

4. Prepare Questions

Prepare thoughtful questions to ask the interviewer. This shows your engagement and interest in the position and company.

- Ask about the company’s production process and quality control measures.

- Inquire about opportunities for professional development and growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Truss Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!