Are you gearing up for an interview for a Truss Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Truss Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

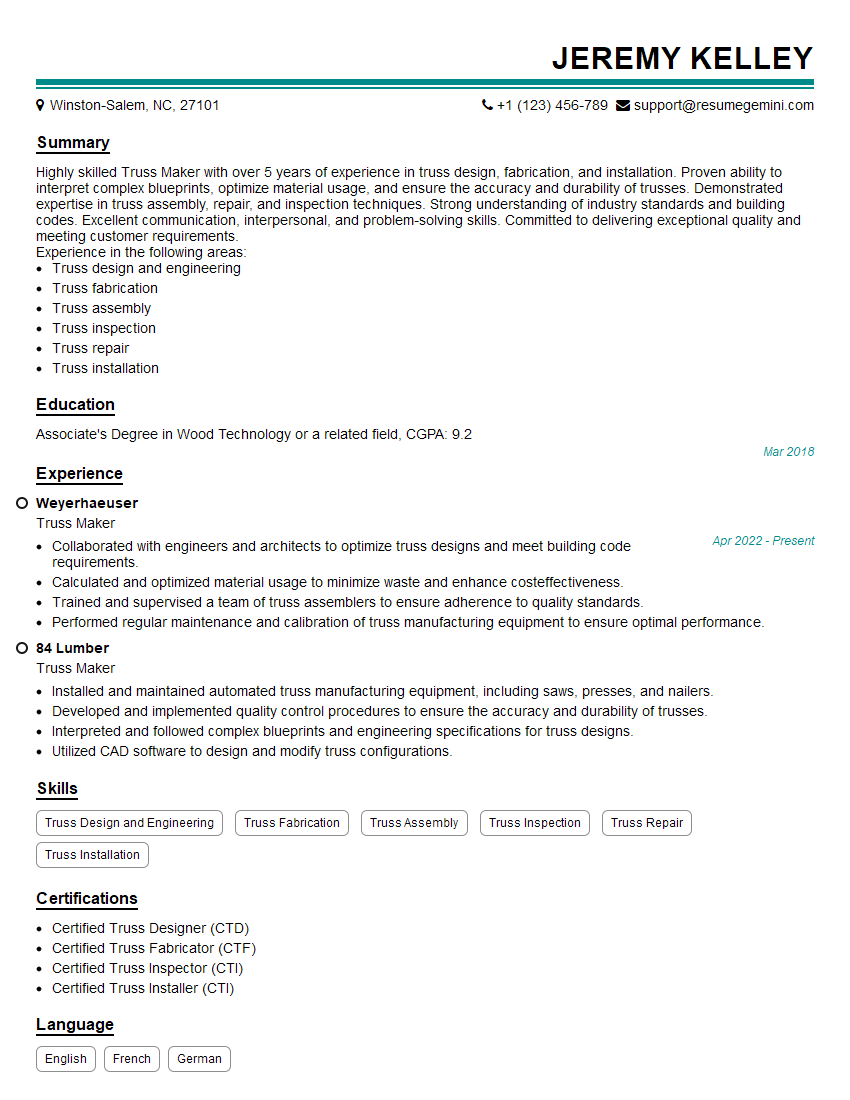

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Truss Maker

1. What are the different types of trusses?

- King post truss: This is the simplest type of truss, consisting of two rafters that meet at the top and are supported by a vertical king post in the center.

- Queen post truss: This truss is similar to a king post truss, but it has two queen posts that support the rafters instead of a single king post.

- Fink truss: This truss is made up of a series of triangles that form a series of “Vs”.

- Fan truss: This truss is made up of a series of triangles that form a “fan” shape.

- Howe truss: This truss is made up of a series of triangles that form a “W” shape.

2. What are the different materials used to make trusses?

- Wood: Wood is the most common material used to make trusses.

- Steel: Steel trusses are stronger than wood trusses, but they are also more expensive.

- Aluminum: Aluminum trusses are lightweight and corrosion-resistant, but they are also more expensive than wood and steel trusses.

3. What are the different factors that affect the design of a truss?

- Span: The span of a truss is the distance between the two supports.

- Load: The load on a truss is the weight that it must support.

- Wind speed: The wind speed that a truss must withstand.

- Snow load: The snow load that a truss must withstand.

4. What are the different steps involved in designing a truss?

- 1. Determine the span and load of the truss.

- 2. Select the type of truss that is best suited for the span and load.

- 3. Calculate the size and spacing of the members of the truss.

- 4. Draw the truss and check its stability.

5. What are the different types of joints used in trusses?

- Butt joint: This is the simplest type of joint, where two members are simply butted together.

- Lap joint: This joint is formed by overlapping two members.

- Scarf joint: This joint is formed by cutting a V-notch in each member and then overlapping the notches.

- Splice joint: This joint is formed by connecting two members with a metal plate or other connector.

6. What are the different types of fasteners used in trusses?

- Nails: Nails are the most common type of fastener used in trusses.

- Screws: Screws are stronger than nails, but they are also more expensive.

- Bolts: Bolts are the strongest type of fastener used in trusses, but they are also the most expensive.

7. What are the different types of equipment used to fabricate trusses?

- Saw: A saw is used to cut the members of a truss.

- Drill: A drill is used to make holes for nails, screws, or bolts.

- Hammer: A hammer is used to drive nails.

- Wrench: A wrench is used to tighten bolts.

8. What are the different types of safety precautions that must be taken when working with trusses?

- Wear safety glasses.

- Wear gloves.

- Use caution when using power tools.

- Be aware of your surroundings.

- Do not work on a truss that is not stable.

9. What are the different types of certification available for truss makers?

- Certified Truss Plant (CTP)

- Certified Truss Designer (CTD)

10. What are the different types of software used to design trusses?

- MiTek SAPPHIRE

- TRUTOOLS

- Psi Truss

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Truss Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Truss Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Truss Makers are skilled professionals who design, build, and install trusses, which are structural frameworks used in construction to support roofs and walls. They work closely with architects, engineers, and other construction professionals to ensure that trusses are designed and installed correctly.

1. Truss Design

Truss Makers must be able to read and interpret blueprints and drawings to design trusses that meet the specific requirements of a project.

- Calculate the loads that the truss will be expected to bear

- Select the appropriate materials for the truss

- Determine the appropriate size and shape of the truss

2. Truss Fabrication

Truss Makers fabricate trusses using a variety of tools and equipment, including saws, drills, and nail guns.

- Cut the lumber to the specified lengths

- Assemble the lumber into the truss

- Secure the joints with nails or bolts

3. Truss Installation

Truss Makers install trusses using a variety of methods, including cranes and forklifts.

- Position the truss in place

- Secure the truss to the supporting structure

- Inspect the truss to ensure that it is installed correctly

4. Quality Control

Truss Makers are responsible for ensuring that trusses are fabricated and installed to the highest quality standards.

- Inspect trusses for defects

- Test trusses to ensure that they meet the specified strength requirements

- Make repairs to trusses as needed

Interview Tips

Preparing for an interview for a Truss Maker position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and Position

Before you go to an interview, it is important to research the company and the specific Truss Maker position you are applying for.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get a sense of what it is like to work there.

- Look at the job description for the Truss Maker position to identify the specific skills and qualifications that the company is looking for.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Provide specific examples of your skills and experience.

- Be enthusiastic and positive in your answers.

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience as a Truss Maker. Be prepared to discuss your skills and experience in detail.

- Highlight your experience in designing, fabricating, and installing trusses.

- Describe your experience with different types of trusses.

- Discuss your experience with quality control procedures.

4. Be Prepared to Answer Questions About Your Safety Knowledge

Truss Makers work in a hazardous environment, so it is important to be knowledgeable about safety procedures.

- Be familiar with OSHA regulations.

- Describe your experience with using personal protective equipment.

- Discuss your experience with working at heights.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Truss Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!