Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tube Blower interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tube Blower so you can tailor your answers to impress potential employers.

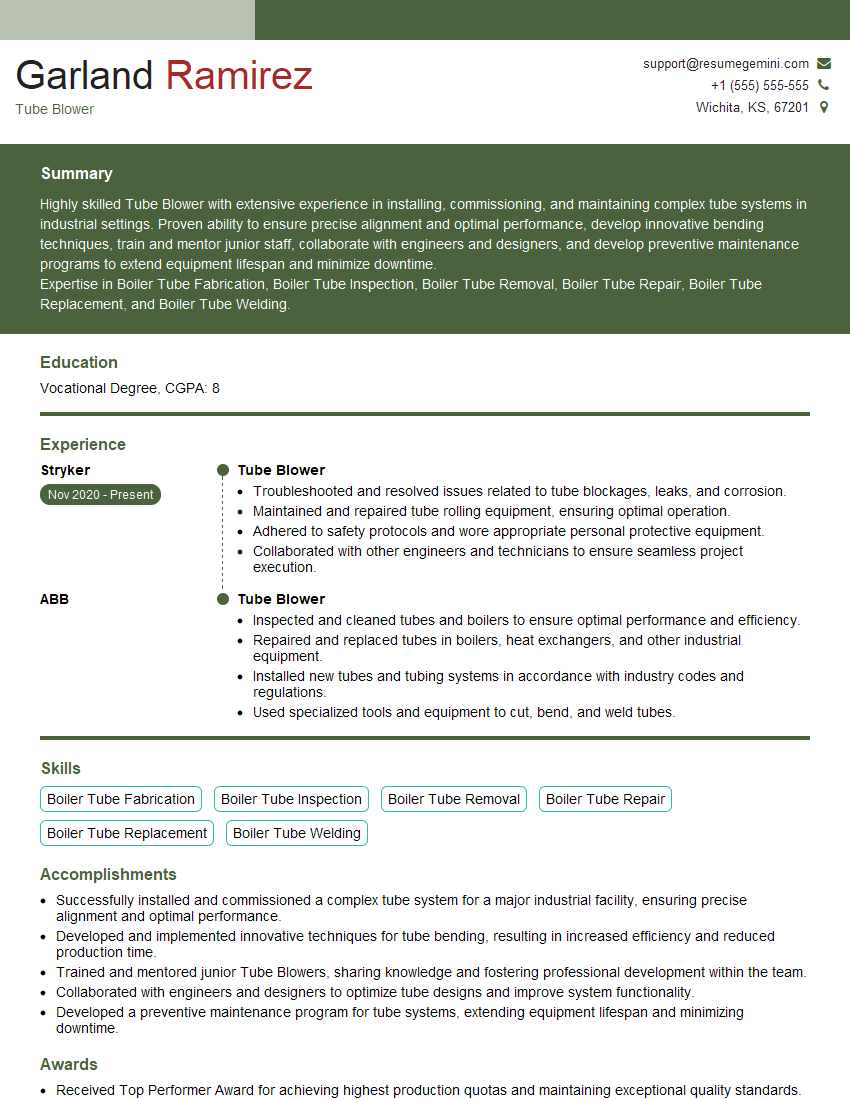

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Blower

1. Tell me about your experience with tube blowing?

I have over 5 years of experience with tube blowing. I have worked on a variety of projects, including power plants, refineries, and chemical plants. I am familiar with all aspects of tube blowing, including boiler tube cleaning, condenser tube cleaning, and heat exchanger tube cleaning.

2. What are the different types of tube blowing equipment?

There are two main types of tube blowing equipment: mechanical tube blowers and air or water powered tube blowers. Mechanical tube blowers use a rotating brush or cutter to clean the inside of tubes.

Air or water powered tube blowers use a high-pressure stream of air or water to clean the inside of tubes.

3. What are the safety precautions that must be taken when using tube blowing equipment?

- Wear appropriate personal protective equipment, such as a mask, gloves, and eye protection.

- Inspect the tube blowing equipment before each use to ensure that it is in good working condition.

- Do not use the tube blowing equipment on live electrical equipment.

- Be aware of the hazards of working with high-pressure air or water.

- Never point the tube blowing equipment at anyone.

4. What are the common problems that can occur when using tube blowing equipment?

- The tube blowing equipment may not be able to remove all of the debris from the tubes.

- The tube blowing equipment may damage the tubes.

- The tube blowing equipment may create a lot of noise.

- The tube blowing equipment may be difficult to use in confined spaces.

5. What are the benefits of using tube blowing equipment?

- Tube blowing equipment can improve the efficiency of heat exchangers.

- Tube blowing equipment can extend the life of tubes.

- Tube blowing equipment can reduce the risk of tube failures.

- Tube blowing equipment can improve the overall performance of a plant.

6. What are the different applications of tube blowing equipment?

- Tube blowing equipment is used to clean the tubes of boilers, condensers, and heat exchangers.

- Tube blowing equipment is used to remove debris, such as scale, rust, and corrosion, from the tubes.

- Tube blowing equipment is used to improve the flow of fluids through the tubes.

- Tube blowing equipment is used to maintain the efficiency of heat exchangers.

7. What are the factors that affect the effectiveness of tube blowing equipment?

- The type of tube blowing equipment.

- The condition of the tubes.

- The type of debris that is being removed.

- The operating conditions.

- The skill of the operator.

8. What are the latest developments in tube blowing technology?

The latest developments in tube blowing technology include the development of new types of tube blowing equipment, such as robotic tube blowers and laser tube blowers. These new types of equipment are more efficient and effective than traditional tube blowing equipment.

9. What are the trends in the tube blowing industry?

The trends in the tube blowing industry include the increasing use of robotic tube blowers and laser tube blowers.

These new types of equipment are more efficient and effective than traditional tube blowing equipment.

10. What are the challenges facing the tube blowing industry?

The challenges facing the tube blowing industry include the increasing demand for tube blowing services and the need to improve the efficiency and effectiveness of tube blowing equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Blowers perform a wide range of tasks related to the installation, repair, and maintenance of tubes and associated equipment in various industries such as power generation, shipbuilding, and manufacturing.

1. Installation and Fabrication

Install, fabricate, and assemble tubes, pipes, and fittings in accordance with blueprints and specifications.

- Cut and shape tubes using specialized tools and equipment.

- Assemble tubes and fittings using welding, soldering, or brazing techniques.

2. Inspection and Maintenance

Inspect tubes and associated equipment to identify defects and ensure proper functioning.

- Conduct visual inspections, ultrasonic testing, and other non-destructive testing methods.

- Perform preventative maintenance tasks, including cleaning, lubricating, and replacing faulty components.

3. Repair and Troubleshooting

Repair damaged tubes and equipment, and diagnose and troubleshoot system malfunctions.

- Repair leaks, cracks, or blockages using specialized tools and techniques.

- Analyze system failures, identify root causes, and implement solutions.

4. Safety and Compliance

Adhere to safety regulations, industry standards, and company policies at all times.

- Wear appropriate personal protective equipment.

- Follow proper handling and storage procedures for tubes and hazardous materials.

Interview Tips

Preparing thoroughly for a Tube Blower interview will increase your chances of making a positive impression and landing the job.

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and their position within the industry.

- Visit the company website.

- Read industry-related publications.

2. Practice Common Interview Questions

Anticipate questions about your skills, experience, and why you are interested in the position.

- Prepare answers that highlight your qualifications and demonstrate your enthusiasm for the role.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

3. Showcase Your Technical Skills

Emphasize your proficiency in tube installation, repair, and troubleshooting techniques.

- Provide examples of complex projects you have worked on.

- Discuss any certifications or specialized training you have obtained.

4. Highlight Your Safety Consciousness

Stress your commitment to safety and your compliance with industry regulations.

- Share examples of safety protocols you have implemented.

- Mention any safety certifications or training you have completed.

5. Professionalism and Communication

Present yourself professionally and communicate clearly and effectively.

- Dress appropriately and arrive on time for the interview.

- Listen attentively to the interviewer’s questions and respond thoughtfully.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tube Blower, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tube Blower positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.