Are you gearing up for an interview for a Tube Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tube Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

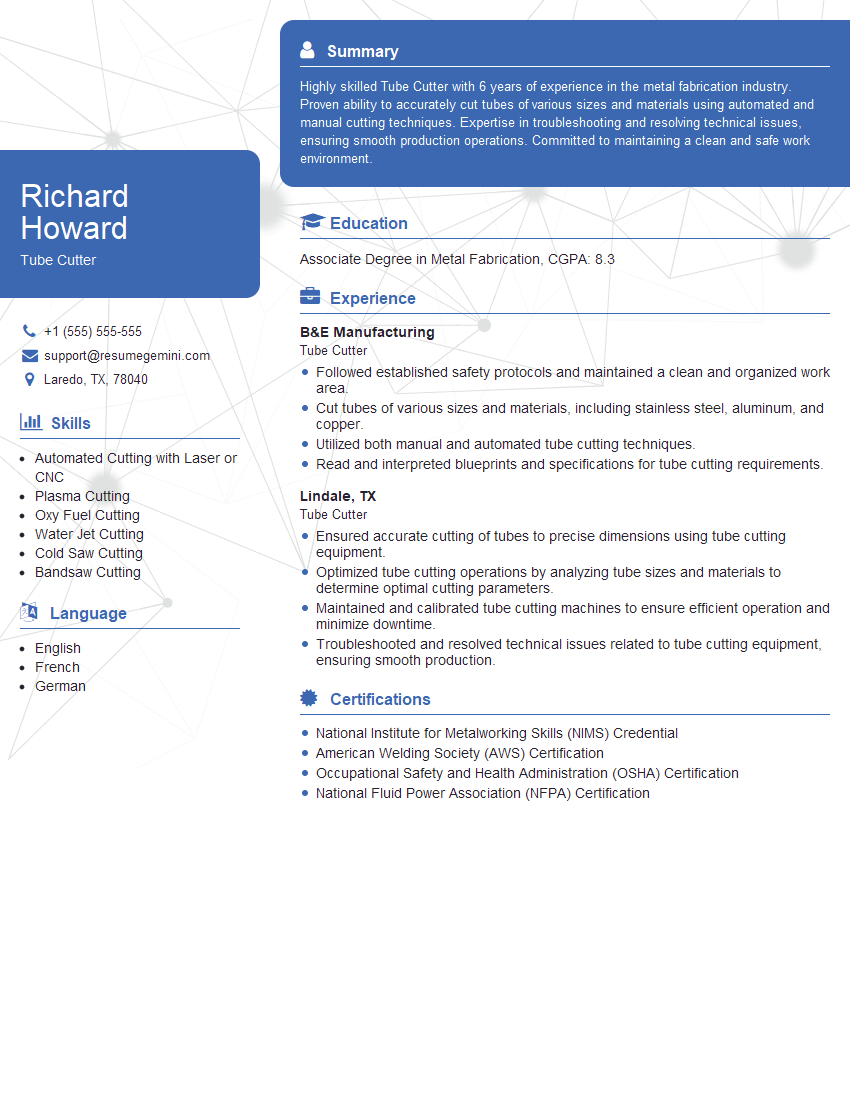

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Cutter

1. What are the different types of tube cutters and their uses?

There are several types of tube cutters, each designed for specific purposes. Here are some of the most commonly used types:

- Manual tube cutters: These are handheld tools that use a rotating cutting wheel to cut through tubes. They are suitable for cutting small-diameter tubes made of soft materials like copper, aluminum, or plastic.

- Power tube cutters: These are electric or pneumatic tools that use a motorized cutting blade to cut through tubes. They are more powerful than manual cutters and can handle larger diameter tubes and harder materials, such as steel or stainless steel.

- Hydraulic tube cutters: These use hydraulic pressure to cut through tubes. They are capable of cutting large-diameter tubes with thick walls, and are often used in industrial applications.

2. What factors should be considered when choosing a tube cutter?

Factors to Consider:

- Tube material: The material of the tube will determine the type of cutter that is best suited. Some cutters are designed specifically for cutting certain materials, such as copper, aluminum, or steel.

- Tube diameter: The diameter of the tube will determine the size of the cutter that is needed.

- Wall thickness: The thickness of the tube wall will affect the cutting difficulty and the type of cutter that is required.

- Cut type: Some cutters are designed for making square cuts, while others can make angled or beveled cuts.

- Portability: Consider whether the cutter will be used in a fixed location or if it needs to be portable for use in various locations.

3. What safety precautions should be taken when using a tube cutter?

Safety is a top priority when using tube cutters. Here are some essential precautions to follow:

- Wear proper safety gear: Wear safety glasses, gloves, and earplugs to protect yourself from flying debris and noise.

- Secure the tube: Ensure the tube is securely held in place before cutting to prevent it from moving or rotating.

- Use a sharp cutting wheel: A dull cutting wheel can increase the risk of slipping and injury.

- Keep hands clear of the cutting area: Never place your hands or fingers near the cutting wheel while it is in operation.

- Lubricate the cutting wheel: Use a lubricant on the cutting wheel to reduce friction and extend its life.

4. How do you maintain a tube cutter?

Regular maintenance is essential to keep a tube cutter in optimal condition. Here are some key maintenance tips:

- Clean the cutter: Regularly remove any metal shavings, dirt, or debris from the cutter using a brush or compressed air.

- Lubricate the cutter: Apply a thin layer of lubricant to the cutting wheel and other moving parts to reduce friction and wear.

- Inspect the cutting wheel: Regularly check the cutting wheel for any damage or wear. Replace it if necessary.

- Store the cutter properly: When not in use, store the tube cutter in a dry and clean environment to prevent rust and corrosion.

5. What are some common problems that can occur when using a tube cutter and how can they be resolved?

Some common problems that can occur with tube cutters include:

- Tube slipping: If the tube is not securely held, it may slip and result in an uneven or inaccurate cut. Ensure the tube is properly clamped or held in place before cutting.

- Dull cutting wheel: A dull cutting wheel can increase the cutting force required and lead to premature wear. Regularly inspect the cutting wheel and replace it when necessary.

- Misalignment: If the tube cutter is not properly aligned, the cut may be uneven or angled. Check the alignment of the cutter before each use and adjust as needed.

- Excessive burrs: Burrs can form on the cut edges of the tube. Use a deburring tool to remove any burrs and ensure a clean and smooth finish.

6. What are the advantages and disadvantages of using a manual tube cutter?

Advantages:

- Manual tube cutters are more affordable than power cutters.

- They are compact and easy to use.

- Manual tube cutters can be used in tight spaces or on uneven surfaces.

Disadvantages:

- Manual tube cutters require more physical effort to operate.

- They are not as powerful as power cutters and may not be able to cut through thick or hard materials.

- Manual tube cutters can be slower than power cutters.

7. What are the advantages and disadvantages of using a power tube cutter?

Advantages:

- Power tube cutters are more powerful than manual cutters and can cut through thicker and harder materials.

- They are faster and more efficient than manual cutters.

- Power tube cutters are easier to use and require less physical effort.

Disadvantages:

- Power tube cutters are more expensive than manual cutters.

- They are larger and heavier, making them less portable.

- Power tube cutters require a power source to operate.

8. What is the difference between a single-point tube cutter and a three-point tube cutter?

Single-point tube cutters have a single cutting wheel that makes contact with the tube at a single point. This type of cutter is suitable for cutting thin-walled tubes made of soft materials such as copper or aluminum.

Three-point tube cutters have three cutting wheels that make contact with the tube at three points. This type of cutter is more stable and can handle thicker-walled tubes and harder materials such as steel or stainless steel.

9. What are some tips for cutting thin-walled tubes?

Here are some tips for cutting thin-walled tubes:

- Use a sharp cutting wheel.

- Apply light pressure when cutting.

- Support the tube on both sides of the cut.

- Cut slowly and carefully.

10. What are some tips for cutting thick-walled tubes?

Here are some tips for cutting thick-walled tubes:

- Use a three-point tube cutter.

- Apply more pressure when cutting.

- Support the tube securely on all sides.

- Cut slowly and carefully.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tube Cutter is responsible for cutting and shaping tubes of different materials, such as metal, plastic, and rubber, using a variety of tools and equipment. Their key responsibilities often include:

1. Tube Preparation

Preparing tubes for cutting by measuring, marking, and securing them securely.

2. Tube Cutting

Cutting tubes accurately and precisely using appropriate saws, cutters, and other equipment, following specified dimensions and tolerances.

3. Tube Shaping

Bending, flaring, or rolling tubes to achieve desired shapes and angles, using specialized equipment and techniques.

4. Equipment Maintenance and Calibration

Maintaining and calibrating tube cutting and shaping equipment to ensure accuracy and safety, including cleaning, lubrication, and regular inspections.

5. Quality Control

Inspecting and measuring cut and shaped tubes to ensure they meet specified requirements and standards.

6. Material Handling

Handling and transporting tubes of varying sizes, weights, and materials safely and efficiently.

7. Safety Compliance

Following safety protocols and regulations related to tube cutting and shaping equipment, including wearing appropriate protective gear and maintaining a clean and organized work area.

Interview Tips

To ace the interview, it’s crucial to highlight your skills and experience relevant to the key job responsibilities. Here are some interview tips to help you prepare:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services, as well as specific details about the Tube Cutter role. This will help you demonstrate your interest and understanding of the position.

2. Highlight Your Skills and Experience

Emphasize your proficiency in tube cutting and shaping techniques, including the types of materials you have worked with. Provide specific examples of projects where you demonstrated precision and accuracy.

3. Prepare for Technical Questions

Expect questions related to your understanding of tube cutting equipment, calibration techniques, and safety protocols. Be prepared to discuss your knowledge of different types of saws, cutters, and bending machines.

4. Showcase Your Safety Knowledge

Interviewers will likely assess your understanding of safety procedures and precautions when working with tube cutting equipment. Highlight your adherence to industry standards and your commitment to maintaining a safe work environment.

5. Practice Your Answers

Prepare responses to common interview questions, such as “Why are you interested in this role?” and “Tell me about a time you faced a challenge in tube cutting.” Rehearsing your answers will help you feel more confident and present yourself professionally.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!