Feeling lost in a sea of interview questions? Landed that dream interview for Tube Drawer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tube Drawer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

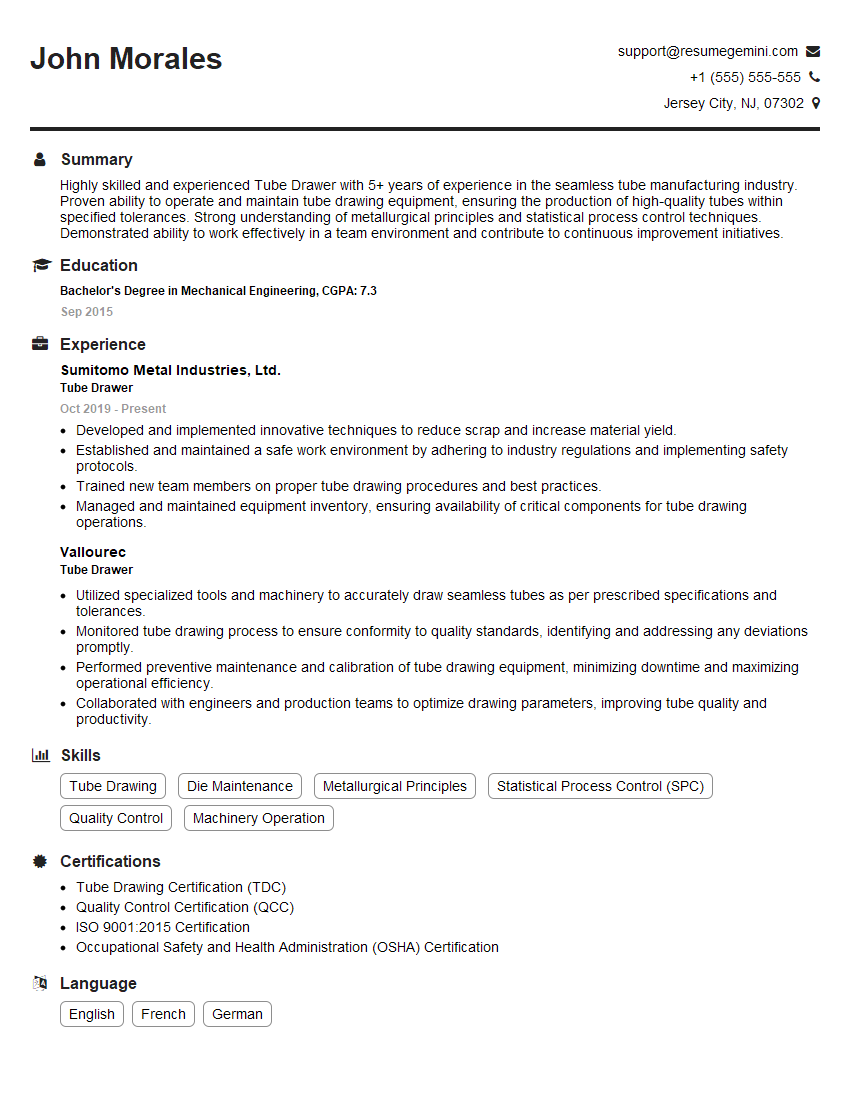

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Drawer

1. What are the different types of tube drawers and their applications?

There are different types of tube drawers, each with its specific applications:

- Manual tube drawers: These are operated manually and are suitable for small-scale production or laboratory applications where precision is not critical.

- Semi-automatic tube drawers: These are partially automated and can be programmed to draw tubes with specific dimensions and tolerances. They are suitable for medium-scale production.

- Fully automatic tube drawers: These are fully automated and can be integrated into production lines. They are suitable for high-volume production and offer consistent quality and precision.

2. What are the key factors to consider when selecting a tube drawer?

When selecting a tube drawer, several key factors should be considered:

Tube material

- The type of material to be drawn into tubes, such as steel, aluminum, copper, or brass.

Tube dimensions

- The required outer diameter, wall thickness, and length of the tubes.

Production volume

- The number of tubes that need to be produced per hour or per day.

Precision requirements

- The tolerances and surface finish required for the tubes.

Automation level

- The level of automation required, from manual to fully automatic.

3. How do you ensure the quality and accuracy of the drawn tubes?

Ensuring the quality and accuracy of drawn tubes involves several steps:

- Proper machine setup: Calibrating and setting up the tube drawer according to the desired tube dimensions and tolerances.

- Quality raw materials: Using high-quality raw materials that meet the specified standards.

- In-process inspection: Regularly checking the tubes during the drawing process to identify any defects or deviations.

- Final inspection: Thoroughly inspecting the finished tubes to ensure they meet the required specifications using measuring instruments such as micrometers or calipers.

4. What are the common maintenance procedures for tube drawers?

Regular maintenance is crucial to keep tube drawers functioning optimally and prevent breakdowns:

- Cleaning: Removing dirt, debris, and metal chips from the machine.

- Lubrication: Applying lubricants to moving parts to reduce friction and wear.

- Calibration: Checking and adjusting the machine’s settings to ensure accurate tube drawing.

- Inspection: Regularly inspecting components for wear or damage and replacing them as necessary.

5. How do you troubleshoot common problems encountered in tube drawing?

Troubleshooting common problems in tube drawing involves identifying the cause and implementing corrective actions:

- Tube surface defects: Adjusting drawing parameters, inspecting dies and mandrels, and ensuring proper lubrication.

- Dimensional inaccuracies: Calibrating the machine, checking die sizes, and adjusting drawing speed.

- Tube breakage: Inspecting raw materials, adjusting drawing force, and checking die alignment.

- Machine breakdowns: Identifying the faulty component, repairing or replacing it, and checking for any underlying issues.

6. What are the safety precautions that should be followed when operating a tube drawer?

Safety is paramount when operating a tube drawer:

- Proper training: Operators should be adequately trained on the safe operation and maintenance of the machine.

- Personal protective equipment (PPE): Safety glasses, gloves, and earplugs should be worn to protect against hazards.

- Machine guarding: Moving parts and potential pinch points should be properly guarded to prevent injuries.

- Emergency stop button: The machine should have an easily accessible emergency stop button for immediate shutdown in case of an emergency.

7. How do you stay updated with the latest advancements in tube drawing technology?

Staying updated with advancements in tube drawing technology is essential for continuous improvement:

- Industry conferences and trade shows: Attending industry events to learn about new technologies and trends.

- Technical journals and publications: Reading industry-specific magazines and journals to stay informed about research and innovations.

- Online resources: Exploring websites and forums dedicated to tube drawing to connect with experts and access technical information.

- Manufacturer training and workshops: Participating in training programs offered by tube drawing machine manufacturers.

8. Describe the role of dies and mandrels in the tube drawing process.

Dies

- Dies are hardened steel rings with a precisely shaped hole through which the tube is drawn.

- They reduce the diameter and wall thickness of the tube.

- The shape and size of the die determine the final dimensions of the tube.

Mandrels

- Mandrels are inserted into the tube during drawing to support its inner diameter.

- They prevent the tube from collapsing and ensure that it maintains its roundness.

- Mandrels can be solid or floating, depending on the tube material and desired finish.

9. Explain the difference between hot and cold tube drawing.

Hot tube drawing

- In hot tube drawing, the tube is heated to a high temperature (typically above 900°C) before being drawn.

- This process makes the tube more malleable and reduces the drawing force required.

- Hot tube drawing is suitable for tubes with large diameters and thick walls.

Cold tube drawing

- In cold tube drawing, the tube is drawn at room temperature.

- This process results in tubes with higher strength and better surface finish.

- Cold tube drawing is suitable for tubes with smaller diameters and thinner walls.

10. What are the environmental considerations associated with tube drawing?

Environmental considerations in tube drawing include:

- Waste management: Proper disposal of waste materials such as lubricants, coolants, and metal chips.

- Energy efficiency: Optimizing machine settings and using energy-efficient equipment to reduce energy consumption.

- Noise pollution: Implementing noise-reducing measures to minimize the impact on the surrounding environment.

- Material recycling: Exploring recycling options for scrap metal and other materials to promote sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Drawer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Drawer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Drawers play a crucial role in the production of various types of tubes used in different industries. Their key responsibilities include:

1. Tube Drawing and Processing

Operate and monitor tube drawing machines to produce tubes of specified dimensions and tolerances.

- Set up and adjust machines for different tube sizes and materials.

- Monitor process parameters such as speed, tension, and temperature to ensure optimal tube quality.

2. Material Handling

Load and unload raw materials (e.g., coils) into the tube drawing machines.

- Inspect incoming materials for defects and damage.

- Transport finished tubes to designated storage areas.

3. Equipment Maintenance

Perform basic maintenance on tube drawing machines.

- Clean and lubricate equipment as per maintenance schedules.

- Identify minor issues and perform troubleshooting to prevent downtime.

4. Quality Control

Inspect and measure tubes to ensure they meet the required specifications.

- Use measuring instruments to check tube dimensions, surface finish, and other quality parameters.

- Maintain quality records and report any non-conformances to supervisors.

Interview Tips

To ace the interview for a Tube Drawer position, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you:

1. Research the Company and Role

Thoroughly research the company, their products, and the specific role you’re applying for. This knowledge will help you understand the company’s needs and demonstrate your interest in the position.

2. Highlight Your Skills and Experience

Emphasize your experience in tube drawing, machine operation, and quality control. Quantify your accomplishments whenever possible, providing specific examples of projects or tasks where you excelled.

3. Prepare for Technical Questions

Tube Drawers may be asked technical questions about the tube drawing process, equipment, and quality standards. Review these concepts thoroughly and be prepared to explain your understanding.

4. Practice Your Communication Skills

Interviewers will assess your communication skills throughout the interview. Practice answering questions clearly and concisely, and be prepared to ask thoughtful questions to show your engagement and interest.

5. Dress Professionally

Dress appropriately for the interview, as it reflects your professionalism and respect for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Drawer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!