Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tube Knitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

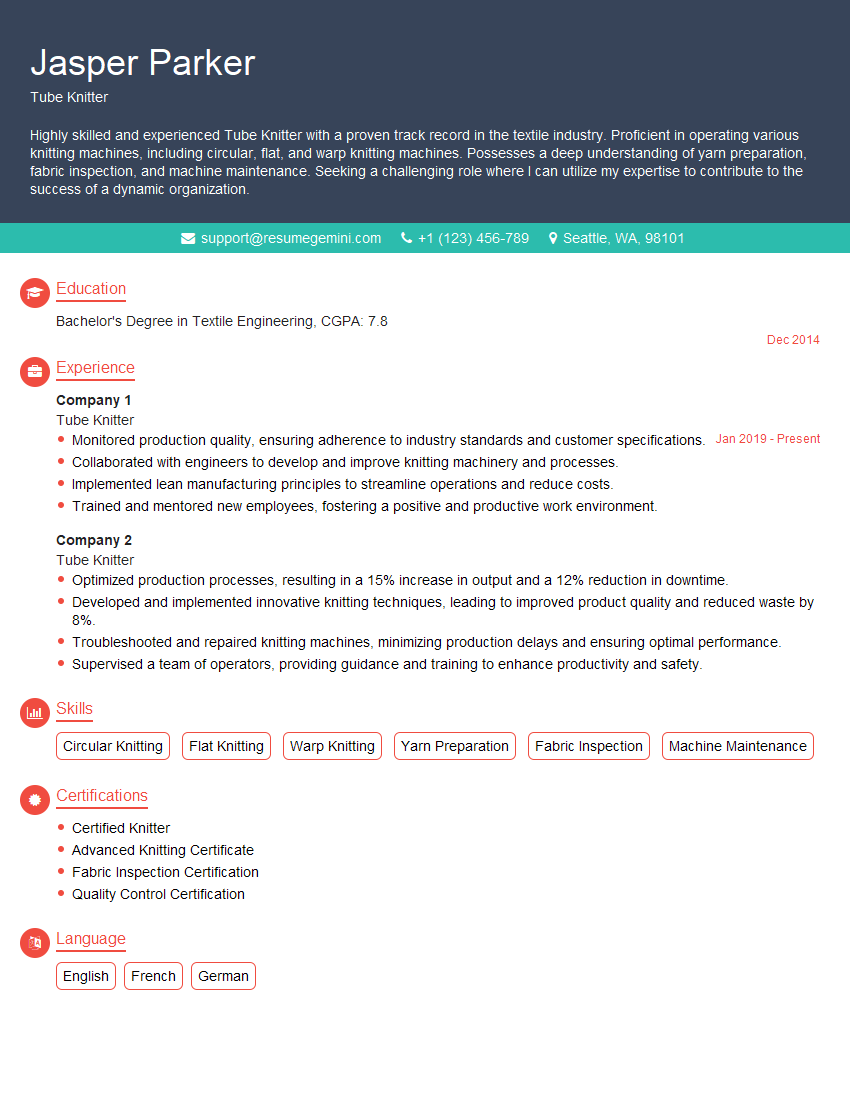

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Knitter

1. Describe the process of setting up a knitting machine for tube production?

- Mount the yarn onto the creel.

- Thread the yarn through the tensioner, guides, and needles.

- Set the knitting machine to the correct stitch pattern and yarn tension.

- Start the knitting machine and monitor the fabric as it is produced.

2. What are the different types of yarns that can be used for tube knitting?

Synthetic yarns

- Polyester

- Nylon

- Spandex

Natural yarns

- Cotton

- Wool

- Silk

3. What are the different factors that can affect the quality of the knitted fabric?

- The type of yarn used.

- The knitting machine settings.

- The tension of the yarn.

- The speed of the knitting machine.

4. What are the different types of knitted fabrics that can be produced on a tube knitting machine?

- Single jersey

- Double jersey

- Rib

- Interlock

5. What are the different applications for tube knitted fabrics?

- Apparel

- Home furnishings

- Industrial fabrics

6. What are the different types of knitting machines that can be used for tube production?

- Circular knitting machines

- Flat knitting machines

7. What are the different types of knitting needles that can be used for tube production?

- Latch needles

- Spring needles

- Compound needles

8. What are the different types of knitting stitches that can be used for tube production?

- Plain stitch

- Rib stitch

- Interlock stitch

9. What are the different types of knitting patterns that can be used for tube production?

- Stripes

- Checks

- Plaids

10. What are the different types of knitting finishing processes that can be used for tube knitted fabrics?

- Dyeing

- Printing

- Finishing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Knitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Knitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube knitters are skilled employees who work in textile mills to operate tube knitting machines. Their primary responsibility is to produce knitted fabric tubes used in the manufacturing of various garments, such as socks, hosiery, and athletic wear.

1. Machine Operation

Tube knitters are responsible for the setup, operation, and maintenance of tube knitting machines. This involves:

- Loading and threading yarn onto the machine.

- Selecting and adjusting machine settings based on fabric specifications.

- Monitoring machine performance and making adjustments as needed to ensure optimal fabric quality.

- Troubleshooting and resolving machine malfunctions to minimize downtime.

2. Fabric Inspection

Tube knitters inspect the fabric produced by the machine to ensure it meets quality standards. They check for defects such as holes, broken stitches, or uneven tension.

- Inspecting fabric width, weight, and texture.

- Identifying and removing defective fabric.

- Making adjustments to machine settings to correct fabric quality issues.

3. Production Management

Tube knitters are responsible for managing fabric production to meet quotas. This involves:

- Scheduling production runs and ensuring machines are operating efficiently.

- Estimating fabric yields and managing yarn inventory.

- Coordinating with other departments to ensure timely delivery of fabric.

4. Safety and Housekeeping

Tube knitters prioritize safety and maintain a clean and organized work environment. They adhere to safety guidelines, wear appropriate protective gear, and maintain their work area free of debris.

- Following safety protocols and reporting any potential hazards.

- Keeping the knitting machine and surrounding area clean.

- Properly handling and storing hazardous materials, such as chemicals or dyes.

Interview Preparation Tips

To ace an interview for a Tube Knitter position, it’s essential to be well-prepared. Here are some tips and tricks to help you impress the interviewers:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Check the company’s website and social media pages.

- Read industry publications and articles.

- Prepare questions about the company’s future plans and growth prospects.

2. Highlight Relevant Skills and Experience

Focus on showcasing your skills and experience that are most relevant to the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your experience in operating tube knitting machines.

- Provide specific examples of fabric quality issues you have identified and resolved.

- Highlight any production management responsibilities you have had.

3. Practice Answering Common Interview Questions

Anticipate and prepare answers to common interview questions related to your skills, experience, and motivation. Practice delivering your answers confidently and concisely.

- “Tell me about your experience with tube knitting machines.”

- “What are the most common fabric defects you have encountered and how did you resolve them?”

- “How do you ensure that fabric production meets quality standards?”

4. Prepare Questions for the Interviewers

Asking thoughtful questions at the end of the interview shows that you are genuinely interested in the position and the company. Prepare questions that demonstrate your curiosity and that are specific to the role.

- “What are the key performance indicators for this position?”

- “What are the opportunities for career growth within the company?”

- “What are the company’s plans for innovation in the tube knitting industry?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tube Knitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tube Knitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.