Are you gearing up for an interview for a Tube Laser Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tube Laser Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

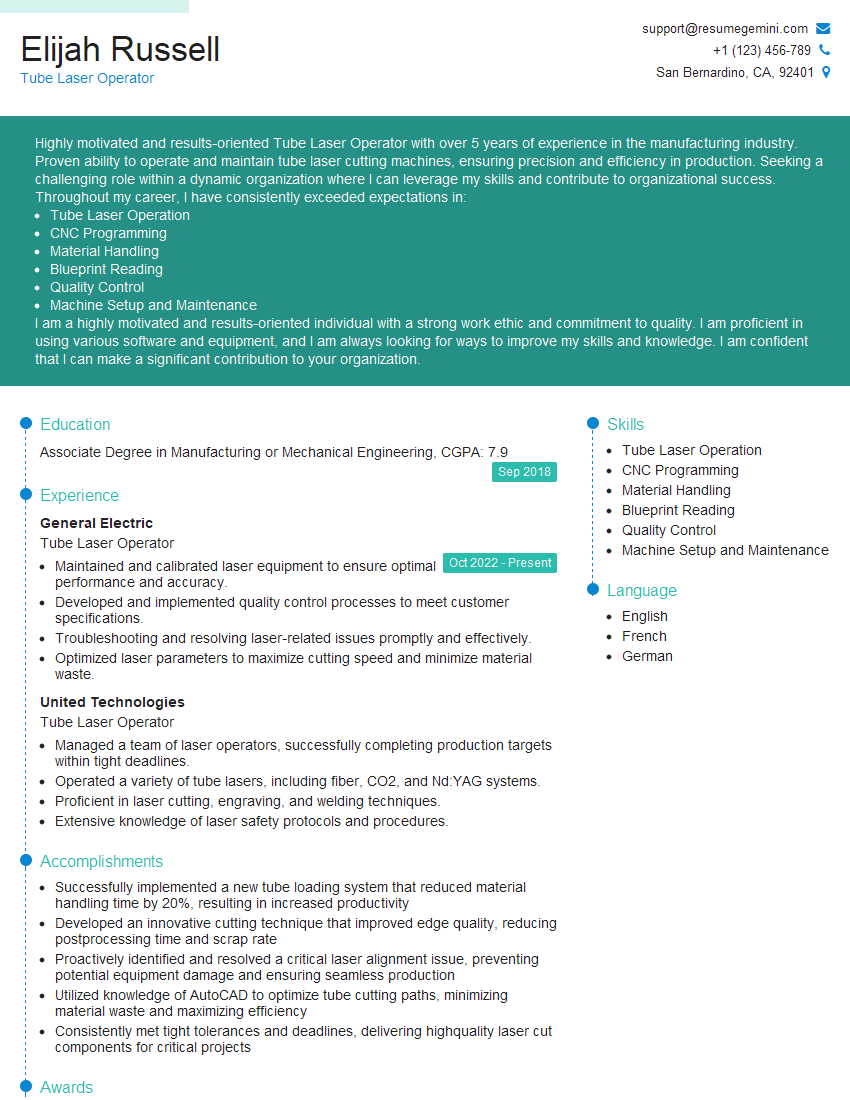

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Laser Operator

1. Describe the process of setting up a tube laser cutting machine?

1. Safety Precautions

- Wear appropriate personal protective equipment (PPE).

- Ensure that the work area is clean and free of hazards.

2. Machine Configuration

- Load the tube into the machine and secure it properly.

- Select the appropriate laser parameters (power, speed, gas pressure).

3. Software Interface

- Import the CAD file and create the cutting path.

- Adjust settings such as cutting speed, acceleration, and pierce delay.

2. How do you determine the optimal cutting parameters for different materials and thicknesses?

1. Material Considerations

- Consider the reflectivity, thermal conductivity, and melting point of the material.

- Experiment with different power settings to find the optimal balance between cutting speed and edge quality.

2. Thickness Variations

- Adjust the cutting speed and power based on the thickness of the material.

- Use a pilot hole or scribe line to assist with piercing thicker materials.

3. Gas Optimization

- Select the appropriate assist gas (e.g., oxygen, nitrogen) to improve cut quality.

- Adjust the gas pressure to optimize shielding and prevent oxidation or dross formation.

3. What troubleshooting steps would you take if the tube laser is not cutting accurately?

1. Mechanical Alignment

- Check the alignment of the laser head and mirrors.

- Ensure that the tube is properly seated and not slipping.

2. Laser Parameters

- Verify that the laser parameters (power, speed, frequency) are set correctly.

- Consider adjusting the focus position to optimize beam quality.

3. Material Properties

- Check if the material is clean and free of contaminants.

- Consider the variations in material thickness and adjust parameters accordingly.

4. How do you calculate the estimated run time for a tube laser cutting job?

1. Material Dimensions

- Measure the length of the tube to be cut.

- Estimate the cutting speed based on the material and thickness.

2. Cutting Path

- Determine the length of the cutting path based on the design.

- Consider the number of piercings and their impact on cut time.

3. Machine Efficiency

- Factor in the acceleration/deceleration time of the laser head.

- Include time for loading/unloading the tube and any setup changes.

5. Explain how you use CAD software to create cutting paths for complex tube geometries

1. Importing Geometry

- Import the 3D CAD model of the tube into the software.

- Ensure that the geometry is properly oriented and scaled.

2. Creating Cut Paths

- Use the software’s tools to create 2D cut paths that follow the tube’s contours.

- Consider the tube diameter, bend radii, and any special features.

3. Optimization and Simulation

- Optimize the cut paths for efficiency and minimize waste.

- Use the software’s simulation features to preview the cutting process and identify any potential issues.

6. Describe the maintenance procedures you follow to ensure the tube laser’s optimal performance

1. Daily Checks

- Inspect the laser head, mirrors, and lenses.

- Clean the workpiece area and remove any debris.

2. Weekly Checks

- Check the laser alignment and calibrate if necessary.

- Inspect the gas filters and replace them as needed.

3. Monthly Checks

- Perform a comprehensive cleaning of the machine.

- Lubricate all moving parts.

7. Explain how you handle and store tube materials before and after cutting

1. Pre-Cutting Handling

- Inspect the tubes for any defects or damage.

- Clean the tubes to remove any contaminants.

- Store the tubes in a dry and protected environment.

2. Post-Cutting Handling

- Remove any burrs or dross from the cut edges.

- Inspect the cut parts for quality.

- Store the finished parts properly to prevent damage.

8. Describe your experience in using different types of tube laser cutting machines

1. CO2 Laser Machines

- Explain the advantages and disadvantages of CO2 laser technology.

- Describe the applications where CO2 lasers are most suitable.

2. Fiber Laser Machines

- Discuss the benefits and limitations of fiber laser technology.

- Highlight the materials and industries where fiber lasers are commonly used.

9. Explain how you optimize the cutting process to minimize waste and maximize productivity

1. Material Yield

- Use nesting software to efficiently arrange cut paths and minimize material waste.

- Consider the tube diameter and bend radii when planning cut patterns.

2. Cutting Efficiency

- Optimize laser parameters (power, speed, gas pressure) to maximize cutting speed and quality.

- Minimize unnecessary movements and reduce machine downtime.

3. Waste Management

- Implement proper waste disposal systems for scrap material.

- Explore recycling options to reduce environmental impact.

10. Describe your communication and collaboration skills in a fast-paced manufacturing environment

1. Communication

- Explain how you maintain clear and effective communication with colleagues, supervisors, and clients.

- Discuss your experience in using communication tools and technologies.

2. Collaboration

- Describe how you work effectively in a team environment.

- Explain your approach to resolving conflicts and fostering a positive work atmosphere.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Laser Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Laser Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Laser Operators are responsible for operating and maintaining tube laser cutting machines in the manufacturing industry. They play a crucial role in ensuring efficient and safe production processes.

1. Operate Tube Laser Cutting Machines

Operate laser cutting machines to cut and shape metal tubes precisely

- Set up and calibrate machines according to specifications

- Load and unload metal tubes

- Monitor cutting processes and adjust parameters as needed

2. Machine Maintenance and Troubleshooting

Perform regular maintenance and troubleshoot any issues with laser cutting machines

- Clean and lubricate machines

- Replace consumables such as optics and nozzles

- Identify and resolve operational problems

3. Quality Control

Inspect and measure cut pieces to ensure they meet quality standards

- Use measuring tools and equipment to verify dimensional accuracy

- Inspect for defects such as burrs, slag, or excessive heat distortion

- Maintain quality control records

4. Safety and Compliance

Follow all safety procedures and regulations related to laser cutting operations

- Wear appropriate personal protective equipment (PPE)

- Handle hazardous materials safely

- Maintain a clean and organized work area

Interview Tips

Preparing thoroughly for a Tube Laser Operator interview can significantly increase your chances of success. Here are some tips to help you prepare and ace your interview:

1. Research the Company and Position

Before the interview, research the company’s history, products, and industry. Learn about the specific requirements of the Tube Laser Operator position. This will show the interviewer that you are serious about the opportunity and have taken the time to understand the company and role.

- Visit the company website and LinkedIn page

- Review job descriptions and company announcements

- Connect with current or former employees on LinkedIn

2. Practice Answering Common Interview Questions

Practice answering common interview questions related to your skills, experience, and qualifications. Prepare examples and anecdotes that demonstrate your abilities as a Tube Laser Operator. Consider using the STAR method to frame your answers:

- Situation: Describe a specific situation or task you faced

- Task: Explain your responsibilities and goals in that situation

- Action: Detail the specific actions you took to address the situation

- Result: Quantify or describe the positive results of your actions

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments whenever possible to demonstrate the impact of your work. For example, you could say, “I increased production output by 15% by optimizing machine settings and implementing new cutting techniques.”

- Review the job description and identify the key skills and experience required

- Provide specific examples from your previous work that demonstrate your proficiency in these areas

- Use action verbs and quantify your results to make your answers impactful

4. Dress Professionally and Arrive on Time

First impressions matter in an interview. Dress professionally and arrive on time to show respect for the interviewer and the company. A neat and well-groomed appearance conveys that you take the interview seriously.

- Choose business attire that is clean, pressed, and appropriate for the industry

- Arrive at the interview location 10-15 minutes early to allow time for any unexpected delays

- Introduce yourself confidently and maintain eye contact throughout the interview

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the opportunity.

- Prepare questions related to the company culture, growth opportunities, or future projects

- Avoid asking questions about compensation or benefits at this stage

- Be polite and thank the interviewer for their time

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tube Laser Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tube Laser Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.