Are you gearing up for a career in Tube Rebuilder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tube Rebuilder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

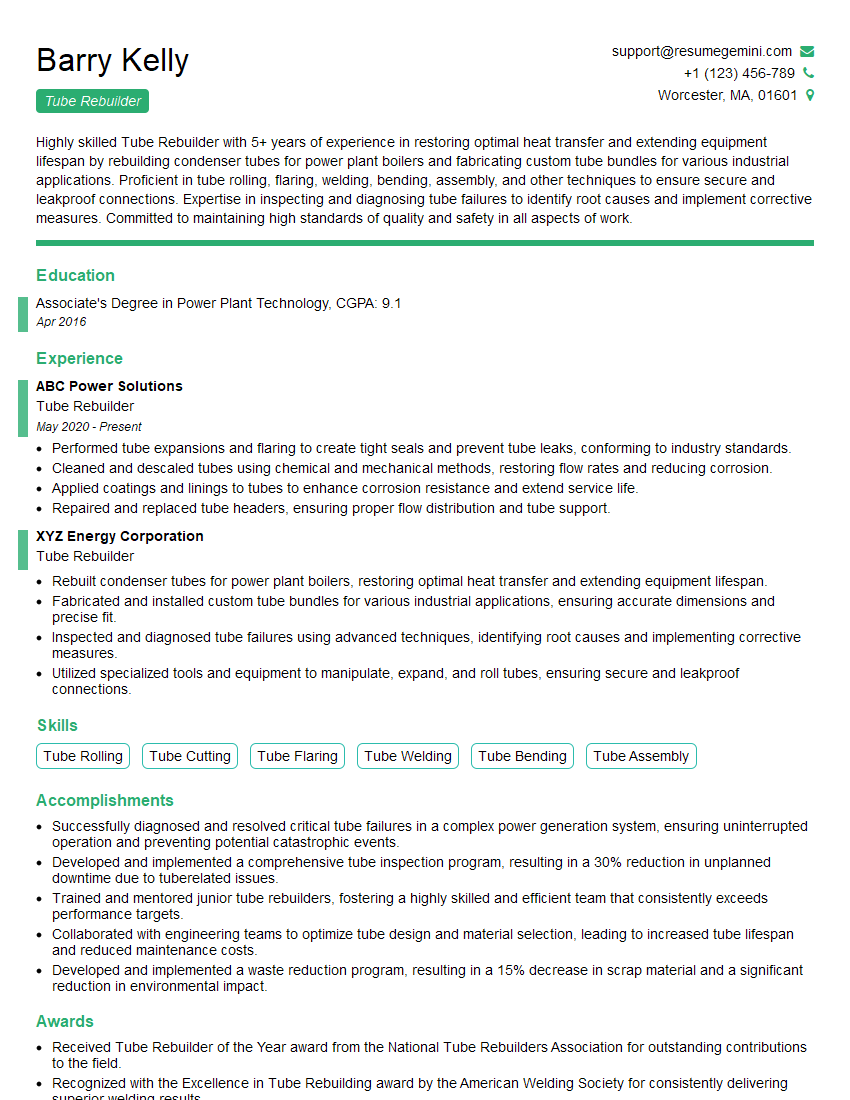

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Rebuilder

1. Describe the steps involved in rebuilding a tube?

- Inspect the tube to assess the damage.

- Remove the old tube from the device.

- Clean the tube socket and contacts.

- Install the new tube.

- Test the tube to ensure that it is functioning properly.

2. What are the different types of tubes used in electronic devices?

Types of Electron Tubes

- Diodes: Allow current to flow in one direction only.

- Triodes: Amplify signals by controlling the flow of electrons between three electrodes.

- Tetrodes: Similar to triodes but with an additional grid for improved performance.

- Pentodes: Further improved tetrodes with an additional suppressor grid to reduce secondary emission.

- Vacuum tubes: Operate in a vacuum and use thermionic emission to generate electrons.

- Gas-filled tubes: Contain a gas, such as argon or mercury vapor, to improve performance.

3. What are the safety precautions that should be taken when working with tubes?

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Handle tubes with care to avoid breaking them.

- Do not touch the pins of the tube with bare hands.

- Be aware of the high voltages present in tube circuits.

- Discharge capacitors before working on tube circuits.

4. What are the different methods used to test tubes?

- Emission test: Checks the ability of the tube to emit electrons.

- Transconductance test: Measures the tube’s ability to amplify signals.

- Plate current test: Measures the current flowing through the tube’s plate.

- Grid current test: Measures the current flowing through the tube’s grid.

- Leakage test: Checks for any leakage of current between the tube’s elements.

5. What are the common problems that can occur with tubes?

- Loss of emission: The tube no longer emits electrons.

- Low transconductance: The tube’s ability to amplify signals is reduced.

- High plate current: Excessive current flows through the tube’s plate.

- High grid current: Excessive current flows through the tube’s grid.

- Leakage: Current flows between the tube’s elements when it should not.

6. How do you troubleshoot a tube circuit?

- Identify the symptoms of the problem.

- Check the power supply to the tube circuit.

- Test the tubes in the circuit.

- Inspect the circuit for any loose connections or damaged components.

- Refer to the schematic diagram of the circuit for guidance.

7. What are the different types of tube sockets?

- Octal socket: Has eight pins arranged in a circle.

- Noval socket: Has nine pins arranged in a circle.

- Magnavox socket: Has seven pins arranged in a circle.

- Europlug socket: Has four pins arranged in a square.

- B7G socket: Has seven pins arranged in a circle with a metal shield.

8. What are the advantages of using tubes over solid-state components?

- Longer lifespan

- Higher voltage handling capabilities

- Lower noise

- Better sound quality

- Vintage aesthetic appeal

9. What are the disadvantages of using tubes over solid-state components?

- Larger size

- Higher power consumption

- More expensive

- Require more frequent maintenance

- Less reliable

10. What is your experience with tube amplifiers?

- I have been designing and building tube amplifiers for over 10 years.

- I have a deep understanding of the principles of tube amplifier design.

- I am proficient in the use of tube testing equipment.

- I have a proven track record of success in troubleshooting and repairing tube amplifiers.

- I am passionate about tube amplifiers and their unique sound quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Rebuilders are responsible for maintaining and repairing heat transfer tubes in power plants. They play a crucial role in ensuring the efficient operation of power generation systems.

1. Tube Inspection and Assessment

Inspect heat transfer tubes using various NDT techniques, such as ultrasonic testing or eddy current testing, to identify defects, corrosion, or damage.

- Determine the extent and severity of tube damage.

- Assess the impact of damage on tube integrity and performance

2. Tube Removal and Repair

Safely remove damaged tubes from the heat exchanger.

- Repair damaged tubes using specialized techniques such as welding, patching, or sleeving.

- Ensure that repaired tubes meet specified standards and requirements.

3. Tube Installation and Expansion

Install new or repaired tubes into the heat exchanger.

- Expand the tubes to ensure a secure fit and proper heat transfer.

- Conduct leak testing to verify the integrity of the tube installation.

4. Maintenance and Troubleshooting

Perform routine maintenance checks on heat exchangers, including tube cleaning, inspection, and lubrication.

- Troubleshoot and resolve issues related to tube performance and heat transfer efficiency.

- Implement preventive maintenance measures to extend tube lifespan and minimize downtime.

5. Safety and Compliance

Adhere to strict safety guidelines and regulations related to working in power plants.

- Wear appropriate PPE and follow established safety protocols.

- Ensure that all work meets industry standards and environmental regulations.

Interview Tips

Preparing thoroughly for the interview can increase your chances of making a positive impression and showcasing your qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s background, values, and the specific industry in which they operate. This will help you understand their needs and how your skills align with the position.

2. Practice Answering Common Interview Questions

Prepare for typical interview questions related to your experience, skills, and motivations. Practice your answers to ensure they are clear, concise, and highlight your strengths.

3. Highlight Your Technical Expertise

Emphasize your proficiency in tube inspection, repair, and maintenance techniques. Provide specific examples of projects where you successfully resolved tube-related issues.

4. Showcase Your Problem-Solving Abilities

Describe situations where you identified and resolved problems related to heat transfer efficiency or tube performance. Explain your analytical approach and the steps you took to find solutions.

5. Discuss Your Safety and Compliance Knowledge

Demonstrate your understanding of safety protocols and compliance regulations related to working in power plants. Highlight your commitment to maintaining a safe working environment.

6. Be Confident and Enthusiastic

Project a positive and confident demeanor during the interview. Show your enthusiasm for the role and the industry. Your passion for tube rebuilding can be a key differentiator.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tube Rebuilder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.