Are you gearing up for an interview for a Tube Sizer and Cutter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tube Sizer and Cutter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

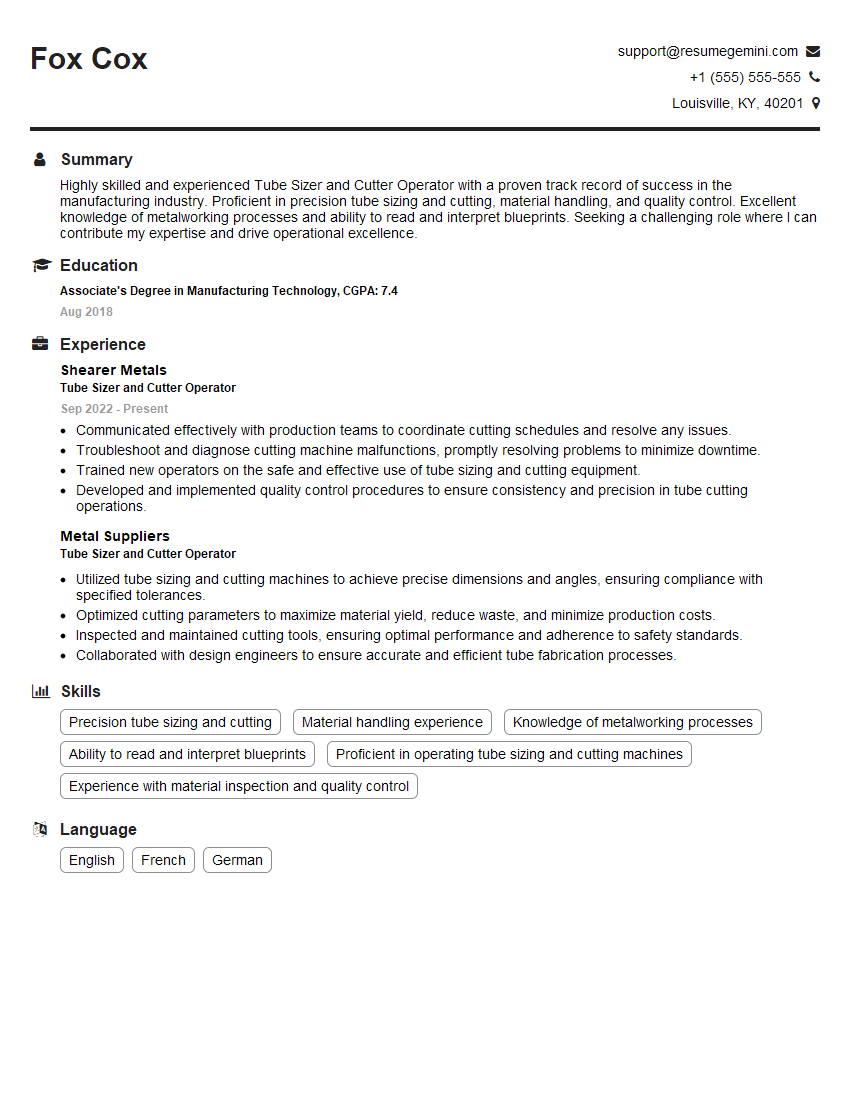

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Sizer and Cutter Operator

1. Explain the key steps involved in the tube sizing and cutting process?

The key steps involved in the tube sizing and cutting process are as follows:

- Loading the tubes: The first step is to load the tubes onto the machine. This is usually done manually, but can also be automated.

- Sizing the tubes: The next step is to size the tubes. This is done by passing them through a series of dies that gradually reduce their diameter.

- Cutting the tubes: Once the tubes have been sized, they are cut to the desired length. This is done using a saw or a shear.

- Unloading the tubes: The final step is to unload the tubes from the machine. This is usually done manually, but can also be automated.

2. What are the different types of tube sizing and cutting machines?

Types of Tube Sizing Machines

- Rotary swaging machines: These machines use a series of rotating dies to reduce the diameter of the tube.

- Stationary swaging machines: These machines use a series of stationary dies to reduce the diameter of the tube.

- Roll forming machines: These machines use a series of rollers to reduce the diameter of the tube.

- Hydroforming machines: These machines use a high-pressure fluid to expand the tube to the desired diameter.

Types of Tube Cutting Machines

- Saws: Saws use a rotating blade to cut the tube.

- Shears: Shears use two blades to cut the tube.

- Laser cutters: Laser cutters use a laser beam to cut the tube.

- Waterjet cutters: Waterjet cutters use a high-pressure jet of water to cut the tube.

3. What are the factors that affect the quality of the tube sizing and cutting process?

The factors that affect the quality of the tube sizing and cutting process are as follows:

- The type of tube: The material and thickness of the tube will affect the way it responds to the sizing and cutting process.

- The condition of the tube: The presence of any defects in the tube will affect the quality of the finished product.

- The type of machine: The quality of the machine will affect the precision and accuracy of the sizing and cutting process.

- The operator: The skill and experience of the operator will affect the quality of the finished product.

4. What are the safety precautions that should be taken when operating a tube sizing and cutting machine?

The safety precautions that should be taken when operating a tube sizing and cutting machine are as follows:

- Wear appropriate safety gear: This includes safety glasses, gloves, and hearing protection.

- Keep the work area clean and free of debris: This will help to prevent accidents.

- Be aware of the location of all controls and emergency stops: This will allow you to react quickly in the event of an emergency.

- Never operate the machine while under the influence of drugs or alcohol: This could impair your judgment and lead to an accident.

- Always follow the manufacturer’s instructions for operating the machine: This will help to ensure that you are using the machine safely and effectively.

5. What is your experience with troubleshooting tube sizing and cutting machines?

I have experience troubleshooting a variety of tube sizing and cutting machines. Some of the most common problems that I have encountered include:

- The machine is not sizing or cutting the tubes to the correct dimensions: This can be caused by a variety of factors, such as worn dies, incorrect machine settings, or a problem with the material being cut.

- The machine is making excessive noise or vibration: This can be caused by a variety of factors, such as loose bearings, a damaged drive system, or a problem with the material being cut.

- The machine is leaking fluid: This can be caused by a variety of factors, such as a damaged hydraulic hose, a loose fitting, or a problem with the pump.

- The machine is not responding to commands: This can be caused by a variety of factors, such as a problem with the electrical system, a software glitch, or a problem with the operator interface.

6. What are your strengths and weaknesses as a Tube Sizer and Cutter Operator?

My strengths as a Tube Sizer and Cutter Operator include:

- I have a strong understanding of the tube sizing and cutting process.

- I am proficient in operating a variety of tube sizing and cutting machines.

- I am able to troubleshoot and repair tube sizing and cutting machines.

- I am a safe and efficient operator.

- I am a team player and I am always willing to help others.

My weaknesses as a Tube Sizer and Cutter Operator include:

- I do not have a lot of experience with large-scale tube sizing and cutting operations.

- I am not fluent in all of the programming languages that are used to control tube sizing and cutting machines.

- I am not always able to work independently.

7. What are your career goals?

My career goals are to:

- Become a more experienced and skilled Tube Sizer and Cutter Operator.

- Gain experience with large-scale tube sizing and cutting operations.

- Learn more about the programming languages that are used to control tube sizing and cutting machines.

- Become a more independent worker.

- Eventually become a supervisor or manager in the tube sizing and cutting industry.

8. Why are you interested in working for our company?

I am interested in working for your company because:

- You are a leader in the tube sizing and cutting industry.

- You have a reputation for producing high-quality products.

- You are committed to safety.

- You offer competitive wages and benefits.

- You are located in a convenient location.

9. What is your salary expectation?

My salary expectation is $25 per hour.

10. Do you have any questions for me?

I do not have any questions for you at this time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Sizer and Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Sizer and Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tube Sizer and Cutter Operators are responsible for accurately sizing and cutting tubes to meet customer specifications. Key job responsibilities include:

1. Tube Sizing and Cutting

Accurately sizing and cutting tubes using manual or automated equipment, ensuring precise dimensions and clean cuts.

2. Machine Operation

Monitoring and operating tube sizing and cutting machines, including tube saws, notchers, and benders. Adjusting settings and performing maintenance as needed.

3. Material Handling

Loading, unloading, and moving tubes and materials safely and efficiently.

4. Inspection and Quality Control

Inspecting tubes for size, shape, and quality, ensuring they meet specifications and customer requirements.

5. Safety Compliance

Adhering to all safety protocols and wearing appropriate protective gear.

Interview Tips

To help candidates ace the interview for a Tube Sizer and Cutter Operator position, consider the following tips:

1. Research the Company and Position

Gather information about the company’s industry, size, products, and services, as well as the specific responsibilities of the Tube Sizer and Cutter Operator role.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating tube sizing and cutting equipment, as well as your knowledge of industry standards and safety procedures. Highlight any previous experience in manufacturing or production environments.

3. Demonstrate Accuracy and Attention to Detail

Give examples of your meticulous approach to work and your ability to consistently produce high-quality results. Explain how you ensure precision in your measurements and cuts.

4. Show Enthusiasm and Motivation

Express your interest in the job and the industry. Explain why you are passionate about working in a manufacturing environment and how your skills can contribute to the company’s success.

5. Be Prepared for Technical Questions

Review the job description and prepare for potential technical questions related to tube sizing and cutting processes, equipment operation, and quality control. Be ready to discuss your knowledge of industry standards and safety regulations.

6. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?”

Next Step:

Now that you’re armed with the knowledge of Tube Sizer and Cutter Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tube Sizer and Cutter Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini