Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tube Splicer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

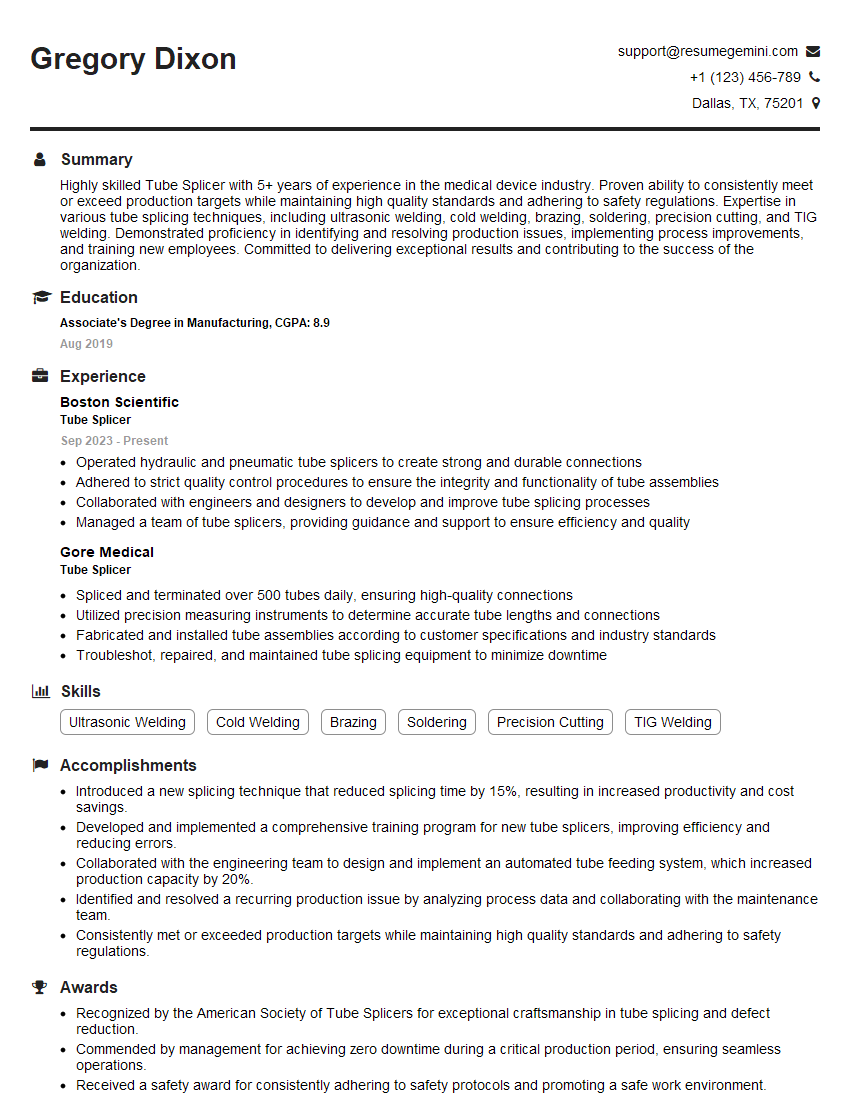

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Splicer

1. What are the different types of tube splicing techniques?

There are various tube splicing techniques, including:

- Compression splicing: Utilizes compression fittings to mechanically join tubes by crimping or compressing them together.

- Soldering: Joining tubes by melting solder around the joint, creating a strong and leak-proof connection.

- Brazing: Similar to soldering, but uses higher temperatures and a different brazing alloy, providing a stronger bond.

- Welding: Fuses tubes together using an electric arc or other heat source, resulting in a permanent and robust connection.

2. What are the critical factors to consider when selecting a tube splicing technique?

Considerations for selecting a tube splicing technique include:

- Material compatibility: Ensuring the splicing technique is suitable for the type of tube material being joined.

- Strength requirements: Selecting a technique that meets the necessary load-bearing capabilities of the joint.

- Environmental conditions: Considering factors such as temperature, moisture, and potential corrosion to ensure the joint’s longevity.

- Cost and time constraints: Evaluating the cost-effectiveness and time required for each technique.

Additional considerations:

- Specialized equipment and training: Assessing the availability of necessary equipment and the training required to perform the technique.

- Safety precautions: Understanding the potential risks and implementing appropriate safety measures for each technique.

3. Describe the steps involved in preparing a tube for splicing.

Preparing a tube for splicing typically involves the following steps:

- Cutting the tube: Precisely cutting the tube to the desired length using a tube cutter or hacksaw.

- Deburring: Removing any sharp edges or burrs from the cut ends of the tube to prevent damage during insertion.

- Cleaning: Thoroughly cleaning the tube ends to remove dirt, debris, or any contaminants that could affect the joint’s integrity.

- Fluxing (for soldering or brazing): Applying flux to the tube ends to improve solder or brazing alloy flow and adhesion.

4. What are the common causes of tube splicing failures?

Common causes of tube splicing failures include:

- Improper preparation: Inadequate cleaning, deburring, or fluxing can result in weak joints or leaks.

- Incorrect technique: Using an unsuitable splicing method or failing to follow proper procedures can lead to joint failure.

- Material incompatibility: Joining tubes made of incompatible materials can result in corrosion or structural problems.

- Overheating or underheating (for soldering or brazing): Using excessive or insufficient heat can damage the joint or weaken the bond.

- Poor quality materials: Using low-quality tubes, fittings, or solder can compromise the joint’s integrity.

5. How do you inspect a tube splice to ensure its quality?

Tube splice inspections typically involve:

- Visual inspection: Examining the joint for any visible defects, such as cracks, gaps, or misalignment.

- Pressure testing: Applying pressure to the joint to check for leaks or any signs of weakness.

- Non-destructive testing (NDT): Using techniques such as ultrasonic or radiographic testing to identify any internal flaws or imperfections.

6. What are the safety precautions to observe when performing tube splicing operations?

Tube splicing safety precautions include:

- Wearing appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and protective clothing to prevent injury.

- Working in a well-ventilated area: Ensuring proper ventilation to avoid exposure to fumes or gases.

- Handling hot materials carefully: Using tongs or gloves to handle heated tubes or fittings to prevent burns.

- Following proper fire safety procedures: Keeping a fire extinguisher nearby and taking precautions to prevent fires or explosions.

- Being aware of electrical hazards: Using insulated tools and grounding equipment to avoid electrical shocks.

7. What is the difference between a mechanical splice and a welded splice?

A mechanical splice joins tubes using mechanical means, such as compression fittings or clamps, while a welded splice fuses the tubes together using heat.

- Mechanical splices: Offer ease of installation, can be disassembled, and are suitable for various tube materials.

- Welded splices: Create permanent and stronger joints, but require specialized equipment and skills, and are limited to weldable materials.

8. How do you determine the correct size and type of fitting for a tube splicing operation?

- Tube diameter: Measuring the outer diameter of the tubes.

- Fitting material: Selecting a fitting material compatible with the tube material and application requirements.

- Fitting type: Choosing the appropriate fitting type based on the desired connection method (e.g., compression, flare, etc.).

- Pressure rating: Ensuring the fitting can withstand the operating pressure of the system.

- Temperature range: Selecting a fitting suitable for the operating temperature range.

9. Describe the process of brazing a tube splice.

Brazing a tube splice involves:

- Preparing the tube ends: Cutting and cleaning the tubes.

- Applying flux: Applying a flux paste to the joint area.

- Assembling the joint: Inserting the tubes into the fitting and aligning them.

- Heating the joint: Using a torch to heat the joint area evenly, ensuring the flux melts and flows.

- Feeding the brazing alloy: Introducing the brazing alloy (e.g., brass or silver-based alloy) into the joint, allowing it to flow by capillary action.

- Cooling the joint: Allowing the joint to cool slowly to prevent cracking.

10. What are the advantages of using compression fittings for tube splicing?

Compression fittings offer several advantages:

- Ease of installation: No special tools or skills required, simply insert the tubes and tighten the nuts.

- Reusable: Can be disassembled and reused, making it convenient for maintenance or modifications.

- Vibration resistance: Designed to withstand vibrations, ensuring a secure connection.

- Wide compatibility: Compatible with various tube materials, including copper, brass, and stainless steel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tube Splicer is responsible for joining and repairing tubes, pipes, and other cylindrical objects. Their expertise is crucial to ensure leak-free connections and maintain the integrity of various systems.

1. Tube Preparation and Joining

Prepare tubes and pipes by cleaning, aligning, and ensuring proper fit. Utilize splicing equipment and techniques to join tubes and maintain structural integrity.

- Apply adhesives, sealants, or mechanical fittings to create strong and lasting connections.

- Inspect and test joints to meet specifications and prevent leaks.

2. Pipe Repair

Diagnose and repair leaks, breaks, and other damages in tubes and pipes. Utilize soldering, welding, or mechanical patching to restore functionality.

- Identify the cause of damage and develop appropriate repair strategies.

- Work in confined spaces and maintain a clean and safe work environment.

3. Equipment Maintenance

Maintain and calibrate splicing equipment to ensure optimal performance. Perform regular inspections and repairs to keep tools and machinery operating efficiently.

- Troubleshoot equipment malfunctions and resolve issues promptly.

- Maintain a clean and organized workspace to prevent accidents.

4. Safety and Compliance

Adhere to safety regulations and industry standards to ensure a safe and compliant work environment. Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols for handling materials and operating equipment.

- Stay informed about industry best practices and participate in safety training programs.

Interview Tips

Preparing for a Tube Splicer interview requires a combination of technical knowledge, practical experience, and a strong understanding of safety measures. Follow these tips to increase your chances of success:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will demonstrate your interest and commitment to the role.

- Visit the company website and explore industry publications.

- Attend industry events or connect with professionals in the field.

2. Showcase Your Technical Skills

Highlight your proficiency in tube splicing techniques, equipment usage, and troubleshooting. Quantify your accomplishments whenever possible.

- Describe specific projects where you successfully joined or repaired tubes.

- Discuss your experience with different types of adhesives, sealants, and mechanical fittings.

3. Emphasize Your Safety Consciousness

Tube splicing involves potential hazards, so employers prioritize safety. Showcase your knowledge of safety protocols, PPE usage, and hazard identification.

- Explain your understanding of industry safety standards and regulations.

- Provide examples of situations where you followed safety procedures to prevent accidents.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest and engagement. Prepare questions about the company’s projects, industry developments, or opportunities for professional growth.

- Inquire about the upcoming projects the company is working on.

- Ask about the company’s commitment to employee training and development.

Next Step:

Now that you’re armed with the knowledge of Tube Splicer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tube Splicer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini