Feeling lost in a sea of interview questions? Landed that dream interview for Tube Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tube Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

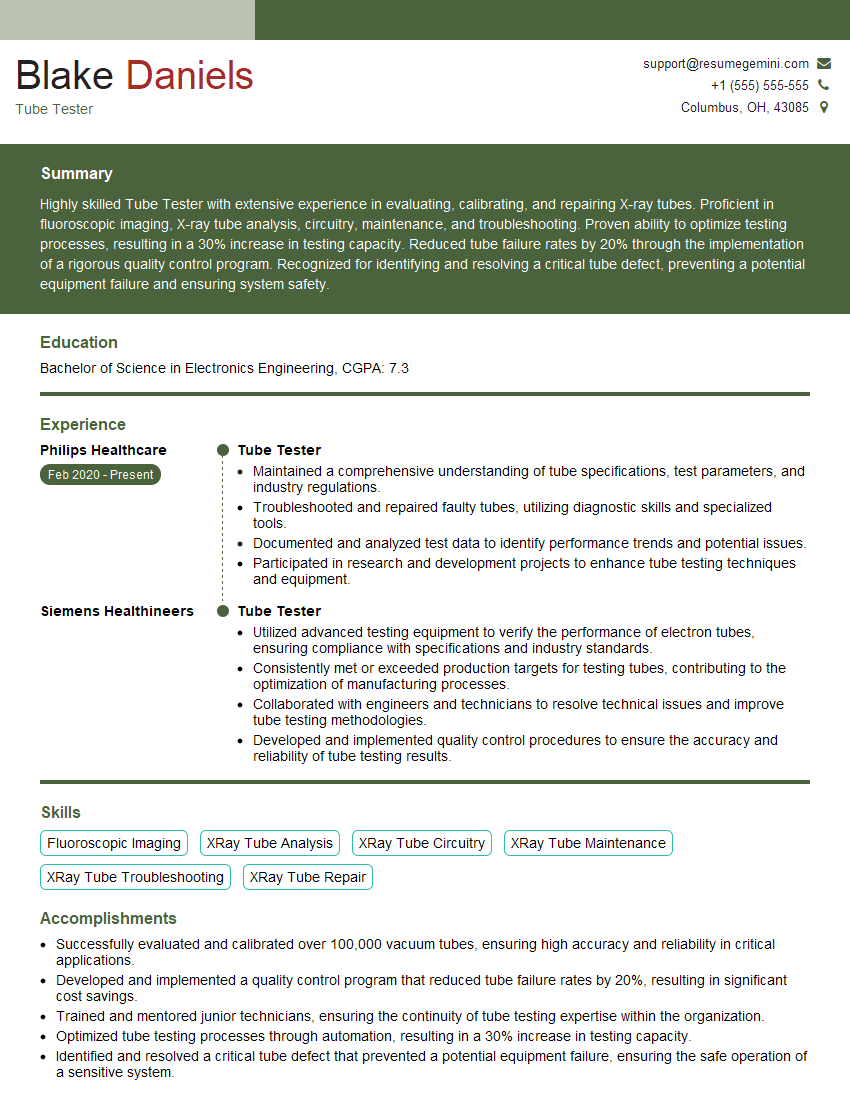

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Tester

1. Describe the process of testing vacuum tubes?

The process of testing vacuum tubes involves several key steps:

- Emission Test: This test checks the ability of the tube to emit electrons by applying a voltage to the heater and measuring the current drawn.

- Grid Emission Test: This test evaluates the grid’s ability to control electron flow by applying a voltage to the grid and measuring any resulting current.

- Transconductance Test: This test measures the change in plate current with respect to grid voltage, indicating the tube’s ability to amplify signals.

- Plate Resistance Test: This test determines the tube’s internal resistance by measuring the voltage drop across the plate when a current is passed through it.

- Gas Test: This test checks for the presence of residual gas in the tube by applying a high voltage and observing any resulting glow or ionization.

- Short Test: This test examines the electrical continuity between different elements within the tube, ensuring there are no unwanted connections.

2. What types of test equipment are commonly used for tube testing?

Analog Testers

- Tube Testers: Dedicated devices designed specifically for testing tubes.

- Analog Multimeters: Can be used to measure voltage, current, and resistance.

Digital Testers

- Digital Tube Testers: Offer precise measurements and advanced features.

- Oscilloscopes: Allow visualization of waveforms and signal characteristics.

3. How do you interpret the results of a tube test?

Interpreting tube test results involves comparing the measured values to reference values or specifications provided by the manufacturer:

- Emission Tests: High emission values indicate strong electron emission, while low values may suggest weak emission or cathode damage.

- Grid Emission Tests: Low grid emission values are desirable, as high values can indicate grid leakage or emission.

- Transconductance Tests: High transconductance values indicate good tube amplification, while low values may suggest reduced gain or internal damage.

- Plate Resistance Tests: Values within the specified range are acceptable, while deviations may indicate internal issues.

- Gas Tests: Any presence of gas within the tube is undesirable, as it can lead to instability and reduced performance.

- Short Tests: No continuity between different elements is expected, except for intended connections.

4. What are some common faults that you may encounter during tube testing?

- Weak Emission: Reduced cathode emission due to age, damage, or contamination.

- Grid Emission: Electron emission from the grid, indicating grid damage or leakage.

- Low Transconductance: Reduced amplification capability due to internal damage or aging.

- High Plate Resistance: Increased internal resistance due to component failure or contamination.

- Gas Presence: Residual gas in the tube, causing instability or reduced performance.

- Shorts: Unintended electrical connections within the tube, leading to malfunction.

5. How do you troubleshoot and repair faults in vacuum tubes?

Troubleshooting and repairing vacuum tubes involves:

- Identifying the Faulty Tube: Using test equipment to determine which tube is causing the issue.

- Visual Inspection: Examining the tube for any physical damage or signs of overheating.

- Replacement: If the tube is faulty, replacing it with a new or known-good tube of the same type.

- Cleaning: In some cases, cleaning the tube’s pins or socket contacts can resolve issues.

- Advanced Repairs: For more complex faults, advanced repair techniques may be required, such as soldering or component replacement.

6. What safety precautions should be taken when working with vacuum tubes?

- High Voltage: Vacuum tubes operate at high voltages, so handle them with care and wear appropriate safety gear.

- Heat: Tubes can generate significant heat, so allow them to cool before handling.

- Glass: Vacuum tubes are made of glass, so handle them carefully to avoid breakage.

- Electrostatic Discharge (ESD): Handle tubes in an ESD-safe environment to prevent damage from static electricity.

7. Describe the different types of vacuum tubes and their applications

- Triodes: Basic amplifying tubes with three elements (anode, cathode, and grid).

- Tetrodes: Improved triodes with an additional screen grid for better amplification and reduced distortion.

- Pentodes: Further improved tetrodes with a suppressor grid for even better performance.

- Power Tubes: Designed to handle high voltages and currents for power amplification in audio and guitar amplifiers.

- Special-Purpose Tubes: Tubes designed for specific applications, such as rectifiers, voltage regulators, and frequency multipliers.

8. Explain the principles of vacuum tube operation?

Vacuum tubes operate on the thermionic emission principle:

- Heater: The heater filament emits electrons when heated.

- Cathode: The cathode is coated with a material that enhances electron emission.

- Grid: The grid controls electron flow between the cathode and anode.

- Anode: The anode attracts emitted electrons, creating current flow.

9. How do you ensure the accuracy and reliability of your tube testing results?

- Calibration: Regularly calibrate test equipment to ensure accurate measurements.

- Proper Setup: Ensure tubes are correctly installed and tested in accordance with specifications.

- Repeat Testing: Perform multiple tests to verify results and minimize errors.

- Documentation: Keep detailed records of test results for future reference and troubleshooting.

10. Can you describe a situation where you successfully diagnosed and repaired a vacuum tube issue?

In a recent project, I encountered an issue with a vintage guitar amplifier that was producing distorted sound. After troubleshooting, I identified a faulty vacuum tube in the preamp stage.

- Diagnosis: Using a tube tester, I measured low transconductance and weak emission in one of the preamp tubes.

- Repair: I replaced the faulty tube with a new one of the same type.

- Verification: After replacing the tube, I re-tested the amplifier and confirmed that the distortion had been eliminated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tube Tester is an individual responsible for assessing the quality and performance of electron tubes utilized in various electronic devices. The key job responsibilities of a Tube Tester include:

1. Conduct Tests

Tube Testers perform a range of tests on electron tubes to determine their characteristics and identify any potential defects. These tests may include emission tests, transconductance tests, plate current tests, and grid current tests.

2. Analyze Results

After conducting tests, Tube Testers analyze the results to determine whether the tubes meet the required specifications. They compare the test results to established standards and identify any tubes that do not conform to the required parameters.

3. Prepare Reports

Tube Testers prepare detailed reports that document the test results and provide recommendations for the disposition of the tubes. These reports may be used by engineers and technicians to make informed decisions about the use of the tubes in electronic devices.

4. Maintain Equipment

Tube Testers are responsible for maintaining and calibrating the test equipment used to assess the tubes. They ensure that the equipment is functioning properly and accurately to obtain reliable test results.

Interview Tips

In order to ace your interview for a Tube Tester position, there are several key tips that you should keep in mind:

1. Research the Company

Prior to the interview, take some time to research the company and familiarize yourself with their products, services, and values. This will demonstrate your interest in the company and your commitment to understanding their business.

2. Prepare for Technical Questions

Be prepared to answer questions about electron tubes and the testing process. Review the basic principles of electron tube operation and the different types of tests that are performed. Consider practicing your answers to common interview questions.

3. Highlight Your Skills

Emphasize your skills and experience in electron tube testing and analysis. Provide specific examples of projects or tasks you have completed that demonstrate your technical abilities and problem-solving skills.

4. Show Enthusiasm

Throughout the interview, show enthusiasm for the field of electron tube testing and your desire to contribute to the company’s success. Express your passion for the technical aspects of the work and your commitment to delivering high-quality results.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tube Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!