Are you gearing up for an interview for a Tube Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tube Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

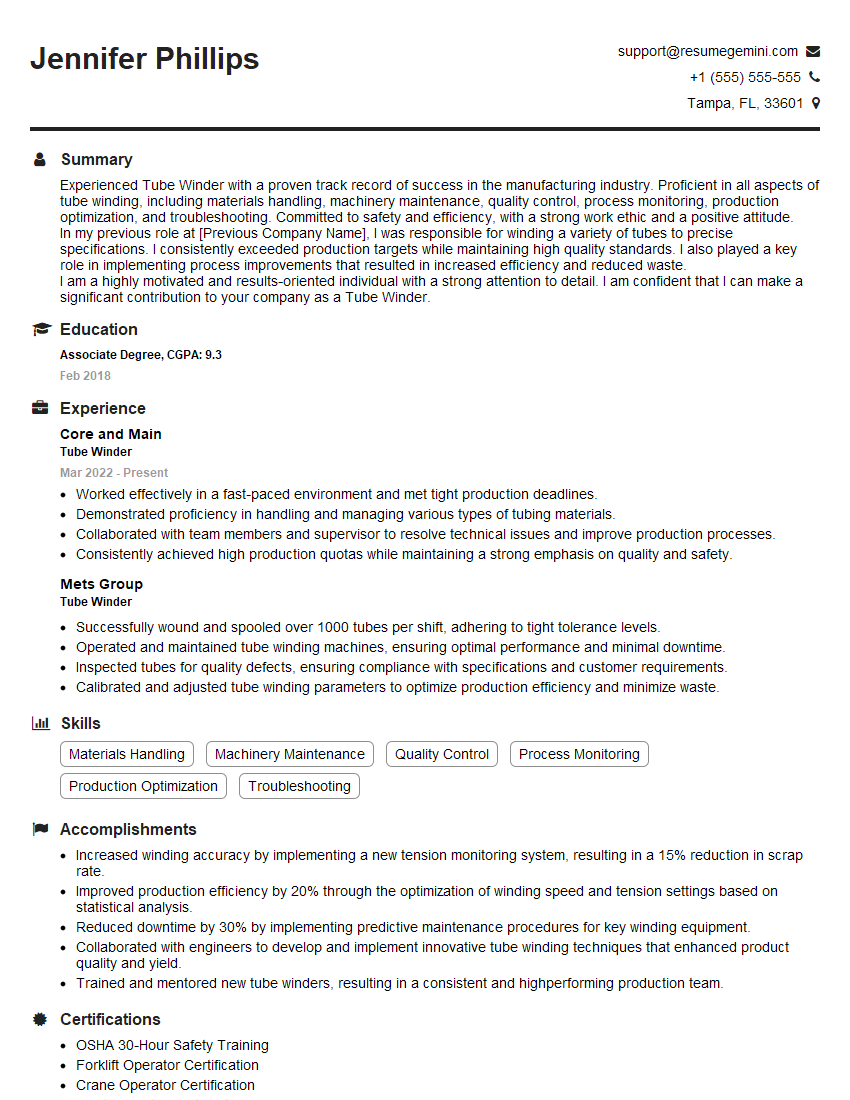

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Winder

1. Explain the process of winding tubes accurately and efficiently?

- First, I prepare the winding machine by setting the winding parameters and ensuring that the core and winding wire are properly loaded.

- I then start the winding process, monitoring the tension, speed, and other parameters to ensure accurate winding.

- During the winding process, I check for any irregularities or defects and make adjustments as needed.

- Once the winding is complete, I inspect the wound tube to verify its quality and meet customer specifications.

2. What are the different types of tubes you have experience winding?

- I have experience winding a variety of tubes, including copper tubes, aluminum tubes, and plastic tubes.

- I am also familiar with the properties of different winding materials and how they affect the performance of the tube.

3. What techniques do you use to ensure the quality of the wound tubes?

- I follow established quality control procedures and use precision measuring instruments to ensure the accuracy of the winding.

- I also perform visual inspections of the wound tubes to check for any defects or irregularities.

- Additionally, I keep detailed records of the winding process, including the parameters used and any adjustments made, to facilitate quality control.

4. How do you troubleshoot and resolve issues that arise during the winding process?

- If any issues arise during the winding process, I first identify the source of the problem.

- Next, I analyze the issue and determine the best course of action to resolve it.

- I may need to adjust the winding parameters, check the equipment for any malfunctions, or make repairs as needed.

- Once the issue is resolved, I verify that the winding process is functioning correctly and meets the required specifications.

5. What safety precautions do you take when winding tubes?

- I always wear appropriate personal protective equipment, such as gloves and safety glasses, when operating the winding machine.

- I ensure that the machine is properly grounded and that all safety mechanisms are in place.

- I am aware of the potential hazards associated with the winding process, such as electrical hazards, and take steps to mitigate these risks.

- I regularly inspect the equipment and report any potential safety issues to my supervisor.

6. What is your experience with tube winding machinery?

- I am familiar with a range of tube winding machinery, including manual, semi-automatic, and fully automatic machines.

- I have experience setting up, operating, and maintaining these machines to achieve optimal performance.

- I am also proficient in using specialized software and instrumentation for tube winding.

7. Are you comfortable working in a fast-paced production environment?

- Yes, I am able to work efficiently and accurately in a fast-paced production environment.

- I am organized and prioritize my tasks effectively to meet deadlines.

- I can work both independently and as part of a team to achieve production goals.

8. What is your understanding of lean manufacturing principles?

- I have a basic understanding of lean manufacturing principles and their application in the production environment.

- I am familiar with concepts such as waste reduction, continuous improvement, and value stream mapping.

- I am eager to learn more about lean manufacturing and how it can be applied to improve the efficiency of the tube winding process.

9. What are your quality control procedures for tube winding? What measuring instruments do you use?

- I follow established quality control procedures to ensure the accuracy and quality of the wound tubes.

- These procedures include visual inspections, dimensional measurements, and electrical testing.

- I use precision measuring instruments, such as calipers, micrometers, and ohmmeters, to verify that the wound tubes meet specifications.

- I keep detailed records of the quality control checks and report any non-conformances to my supervisor.

10. Describe a time when you faced a challenging situation while tube winding and how you overcame it.

- Once, I encountered an issue where the tube being wound was not meeting the required specifications.

- After troubleshooting, I determined that the winding tension was not set correctly.

- I adjusted the tension settings and recalibrated the machine, which resolved the issue and allowed me to produce tubes that met the required quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Tube Winder plays a significant role in the production process by operating various machines to wind tubes and ensure their quality.

1. Machine Operation

• Operate tube winding machines to produce tubes of various sizes and types.

• Adjust and calibrate machine settings to achieve optimal winding performance.

• Monitor the winding process to ensure the production of high-quality tubes.

2. Quality Control

• Inspect tubes for defects and deviations from specifications.

• Conduct dimensional checks and physical tests to ensure that tubes meet quality standards.

• Identify and resolve issues that impact tube quality.

3. Maintenance and Troubleshooting

• Perform regular maintenance and cleaning on winding machines.

• Troubleshoot equipment issues and perform minor repairs to ensure smooth operations.

• Maintain a safe and efficient work environment.

4. Production Planning

• Plan and schedule tube production in line with demand.

• Coordinate with other departments to ensure the availability of materials and resources.

• Monitor production efficiency and identify areas for improvement.

Interview Preparation Tips

To prepare for an interview as a Tube Winder, it is important to thoroughly understand key job responsibilities and develop responses that highlight relevant skills and experience.

1. Technical Expertise

• Review the job description to understand the specific equipment and winding techniques used in the role.

• Practice explaining your experience in operating tube winding machines and performing quality control.

2. Quality Orientation

• Emphasize your attention to detail and commitment to producing high-quality tubes.

• Provide examples of your success in identifying and resolving quality issues.

3. Troubleshooting Skills

• Highlight your problem-solving abilities and experience in troubleshooting machine malfunctions.

• Describe situations where you identified the root cause of an issue and implemented effective solutions.

4. Production Planning Knowledge

• Explain your understanding of production planning principles and how you can contribute to optimizing production efficiency.

• Share examples of how you planned and scheduled tube production to meet customer requirements.

Example Outline

• Tell me about your experience operating tube winding machines.

• Describe a time when you identified and resolved a quality issue with a tube.

• How do you approach troubleshooting technical problems with winding equipment?

• Explain how you plan and schedule tube production to ensure on-time delivery.

Next Step:

Now that you’re armed with the knowledge of Tube Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tube Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini